NX1 effective in manufacturing sites

The NX1 can reduce cycle times through high-speed, high-precision control and increase machine availability in conjunction with distinctive sensors and automation devices, continuously improving productivity while optimizing information utilization, safety measures, and quality control.

Three examples of effective applications for improving productivity

Application case study 1: Increase speed and precision of servo press machine

Combined with the function blocks in the SYSMAC-XR013 Servo Press Library, the NX1 Controller helps improve speed and quality of the pressing process. The dedicated controller for servo press is no longer required.

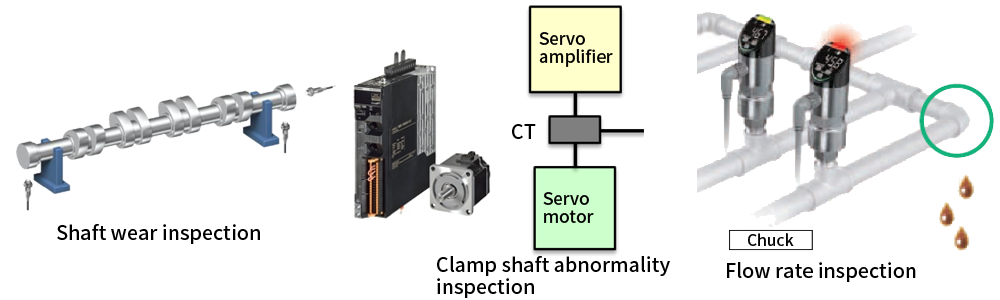

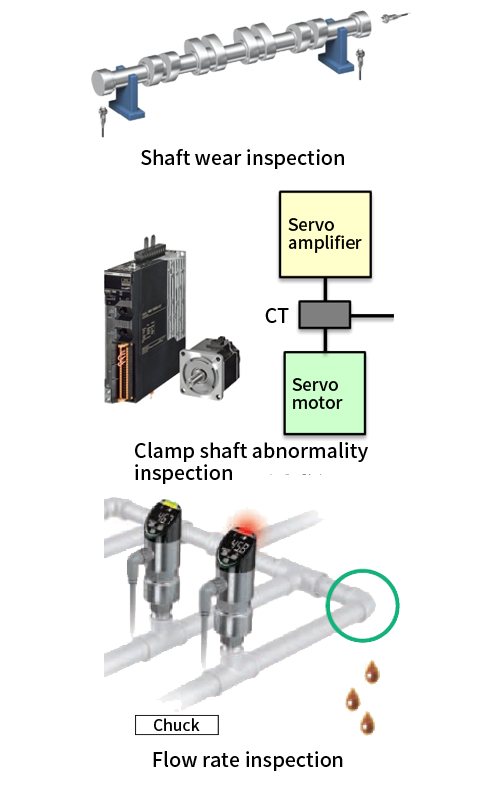

Application case study 2: Reduce downtime of processing machine through predictive management

IO-Link sensors can be used for predictive management of existing machines where periodic inspections are necessary or unscheduled downtime occurs.

Inspections based on intuition and experience can be visualized, and invisible signs (e.g., ram thinning and thickening, lack of lubrication, biting, and cycle delay) can be detected. Data collection allows users to check the relevance of processing quality.

Application case study 3: Monitor motor status of mixing machine or homogenizer

The K6CM Motor Condition Monitoring Device can be used to monitor current using a motor cable, which enables error monitoring. Installing this monitoring device in a control panel eliminates the risk of contamination by foreign matter, preventing sudden stoppage.

Sysmac Studio works for productivity throughout lifecycle

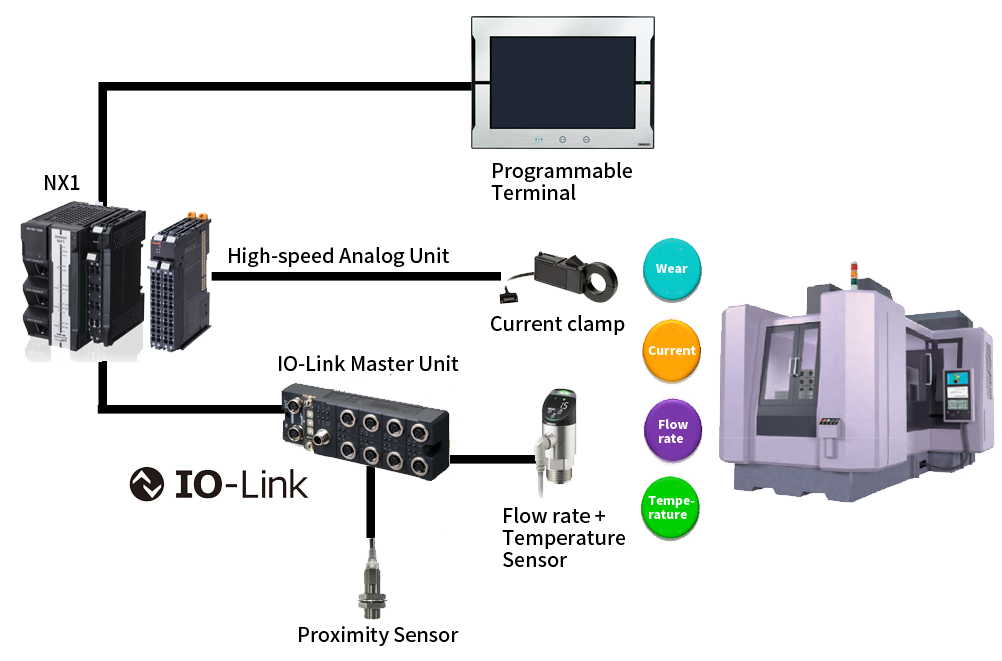

Version control function improved by Git

Sysmac Studio is the Integrated Development Environment (IDE) designed to be your automation companion for your machine’s or system’s entire lifecycle from design to verification and maintenance.

The intuitive user interface, PLCopen programming, and the Project Version Control function* keep team working smoothly.

The Project Version Control function* combined with the version control system Git™ significantly reduces time and effort require to change the master and merge changes in the multi-user environment.

For example, when code developed by multiple users is merged, the functions to merge changes automatically and resolve conflicting changes make merging easier and faster. The users can even revert to the previous revision after graphically comparing the current project with a previous one.

Since common programs between different machines can be centrally managed, machine variations and customizations can be handled efficiently.

* This function can be used by applying the Team Development Option to Sysmac Studio version 1.20 or higher. This function is supported by the NX1 CPU Unit version 1.16 or later.

Git and the Git logo are either registered trademarks or trademarks of Software Freedom Conservancy, Inc., corporate home of the Git Project, in the United States and/or other countries.

Easy to understand project records

Easy to find changes in code

Easy to apply changes in variant machine program

Download our product catalog

for more information!

for more information!

NX1 Machine Automation Controller

Photographs are for illustration purposes only and do not represent actual applications.

Images used under license from Shutterstock.com.

The system configurations in this page are for reference purposes only.

Sysmac is a trademark or registered trademark of OMRON Corporation in Japan and other countries for OMRON factory automation products.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

Safety over EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

EtherNet/IP™, CIP Safety™, CompoNet™, and DeviceNet™ are trademarks of ODVA.

OPC and OPC UA are trademarks of the OPC Foundation.

Other company names and product names in this page are the trademarks or registered trademarks of their respective companies.

Microsoft product screen shot(s) reprinted with permission from Microsoft Corporation.

The product photographs and figures that are used in this page may vary somewhat from the actual products.

Images used under license from Shutterstock.com.

The system configurations in this page are for reference purposes only.

Sysmac is a trademark or registered trademark of OMRON Corporation in Japan and other countries for OMRON factory automation products.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

Safety over EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

EtherNet/IP™, CIP Safety™, CompoNet™, and DeviceNet™ are trademarks of ODVA.

OPC and OPC UA are trademarks of the OPC Foundation.

Other company names and product names in this page are the trademarks or registered trademarks of their respective companies.

Microsoft product screen shot(s) reprinted with permission from Microsoft Corporation.

The product photographs and figures that are used in this page may vary somewhat from the actual products.