In the automotive parts industry, vehicles are becoming more complex, and automotive parts are more standardized. As manufacturers are under increasing pressure to ensure parts quality, there is growing demand for full inspection and full traceability (item-level data management) rather than random inspection and lot management.

Full traceability requires an advanced system that is designed and operated by engineers with expertise to collect and store “larger amounts of data” “in more real time” from production machines.

Also prevention of impact on production cycle times and control performance needs to be considered.

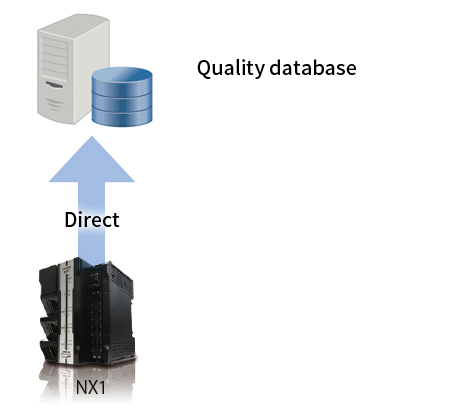

To solve this challenge, we have developed the NX1 Controller with database connection functionality that allows control engineers to collect and store item-level data while maintaining productivity.

Full inspection

Fast, precise, and reliable detection

Nowadays, full inspection is taking the place of random lot inspection.

In-line inspection is ideal to carry out full inspection without sacrificing productivity.

This requires a high-speed, high-precision automated inspection system.

Some high-precision vision sensors can be used for appearance inspection instead of human eyes, and a controller, such as PLC, can perform high-speed processing for inspection while providing control.

Full traceability

Markets require full traceability.

Complete and reliable data collection is indispensable to meeting this demand.

In the automotive, food, and pharmaceutical industries where strict quality control is essential, there is a need to respond to increasing quality risks.

Quality management systems have to conform to the IATF 16949 international standard in the automotive industry where small failure can cause a serious accident. This conformance requires traceability for tracking and managing component parts in detail.

One of the means is collection and utilization of traceability information. To obtain and reliably manage production records, mass data must be collected at high speed without compromising production efficiency.

What is IATF 16949:2016?

Developed by the International Automotive Task Force (IATF) members, IATF 16949:2016 is the international standard for automotive quality management systems. The document submitted to ISO has been revised to meet customer requirements.

The goals of this standard are: (1) Continual improvement, (2) Prevention, (3) Reduction of variation, and (4) Reduction of waste. This standard aims for consistent quality according to automotive quality management system (QMS) requirements for suppliers.

What NX1 can do

The NX1 can directly access databases, reliably storing inspection data of all products.

- No gateway computer needed (PLC and FB used)

- Fastest-in-class communication speed of 50 ms (up to 1,000 products/min)

- Data collection without affecting control performance

- Saving image and inspection data together

- Easy programming using function blocks

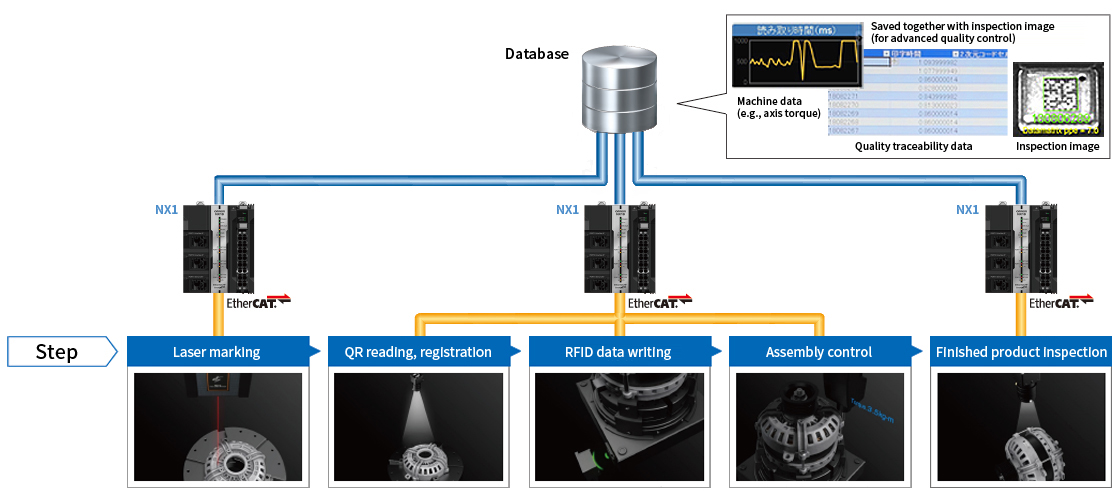

Example of assembling automotive electrical components

Information on traceability includes unique identification numbers given to all component parts, information for management and assembly in the factory, and image data.

The NX1 Controller can collect a complete set of different types of traceability data.

Application case study

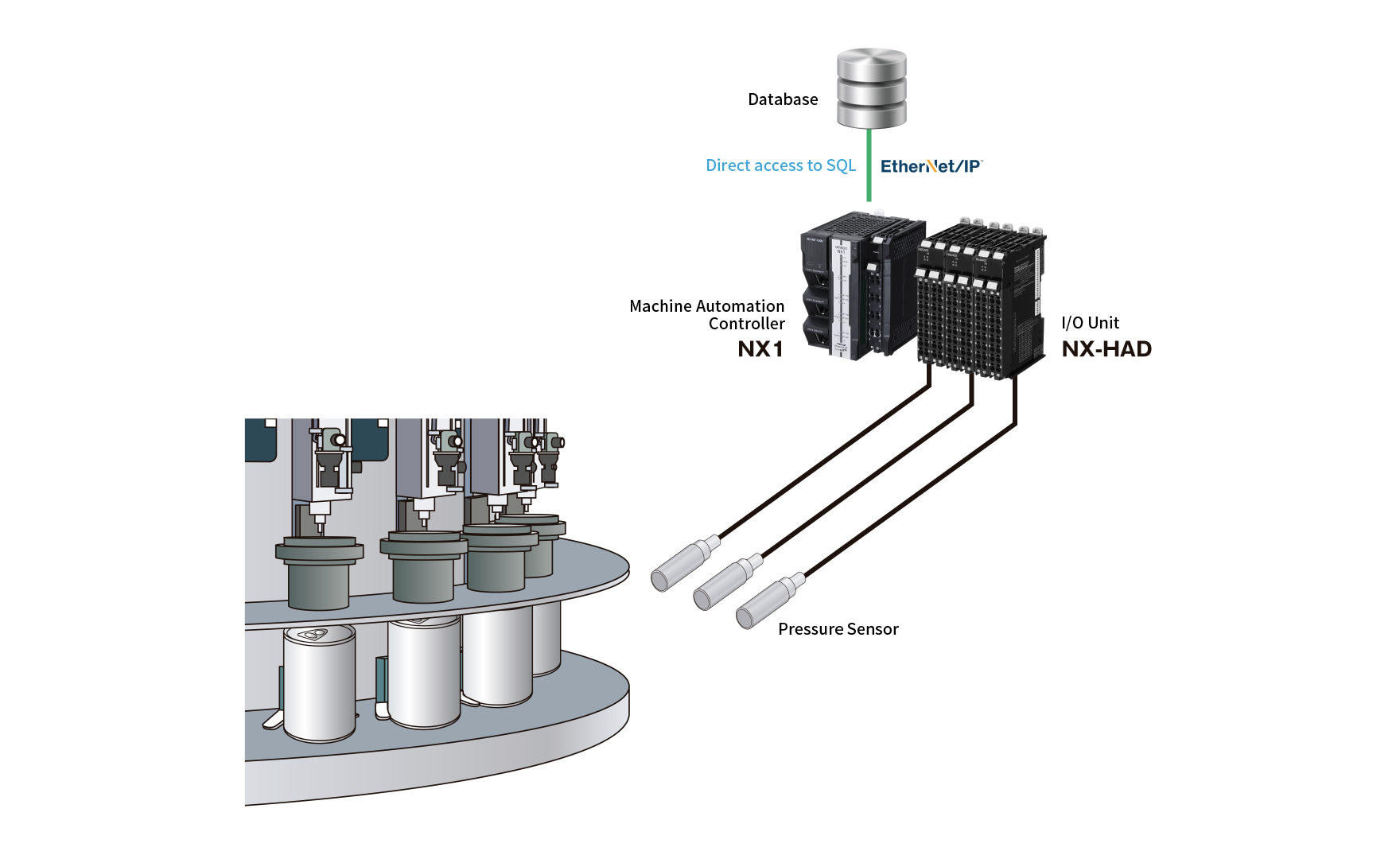

Beverage can leakage tester

Air leakage is detected to identify holes in cans.

The combination of the NX-HAD High-speed Analog Input Unit and the NX1 Controller speeds up in-line full inspection.

The NX-HAD High-speed Analog Input Unit provides:

- High resolution of up to 1/64000 to measure even subtle pressure changes, enabling detection of smaller holes.

- High-speed sampling every 5 μs from 4 channels at the same time, increasing inspection speed by 15% compared with conventional testers.

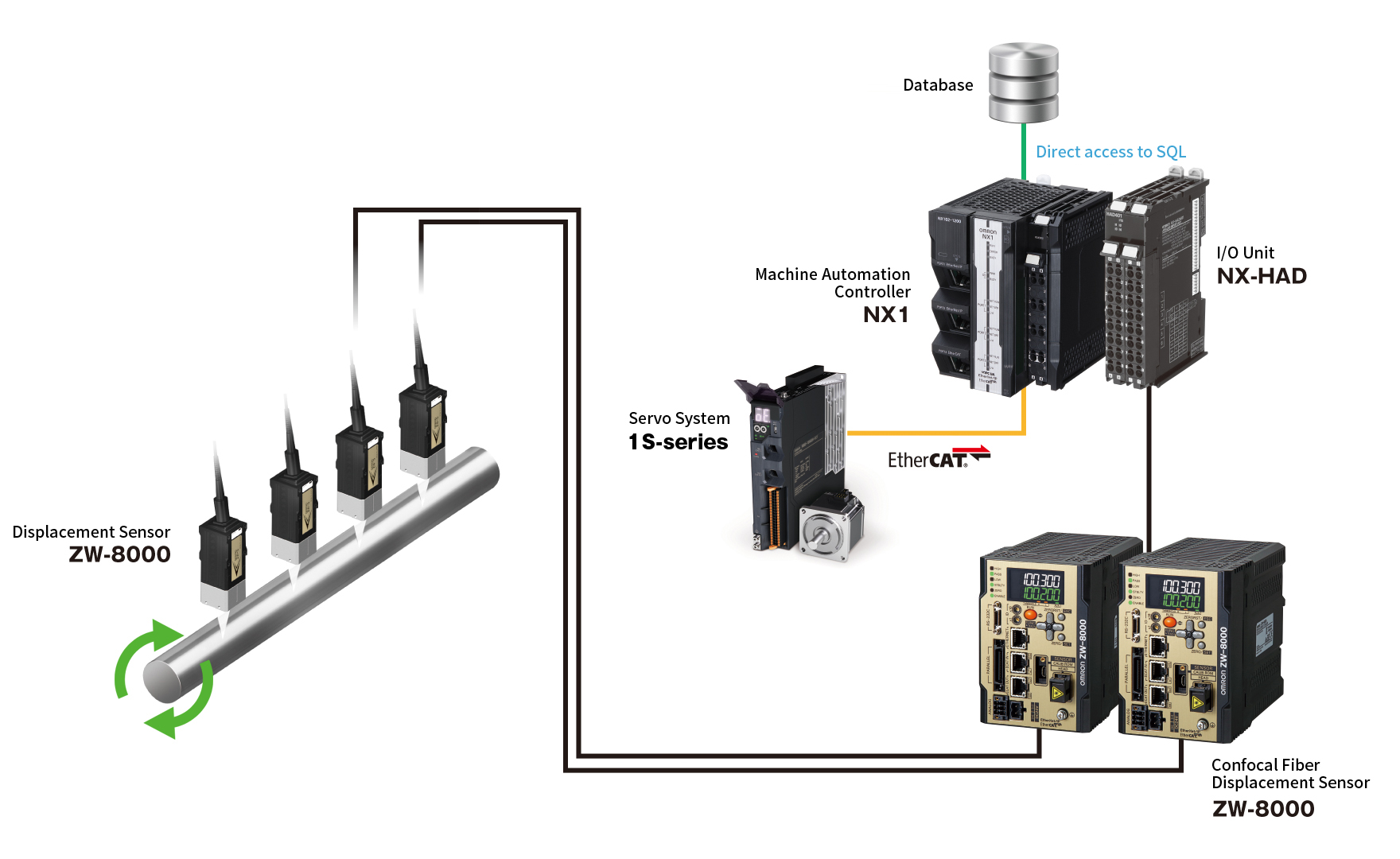

Roundness inspection for shafts

The ZW-8000 Confocal Fiber Displacement Sensor, the NX-HAD High-speed Analog Input Unit, and the NX1 Controller are used together to measure roundness of shafts.

The NX-HAD High-speed Analog Input Unit can:

- Obtain data synchronously from multiple channels, facilitating comparative analysis of trajectory data.

- Acquire precise trajectory data without noise through insulated channels that minimize mutual interference.

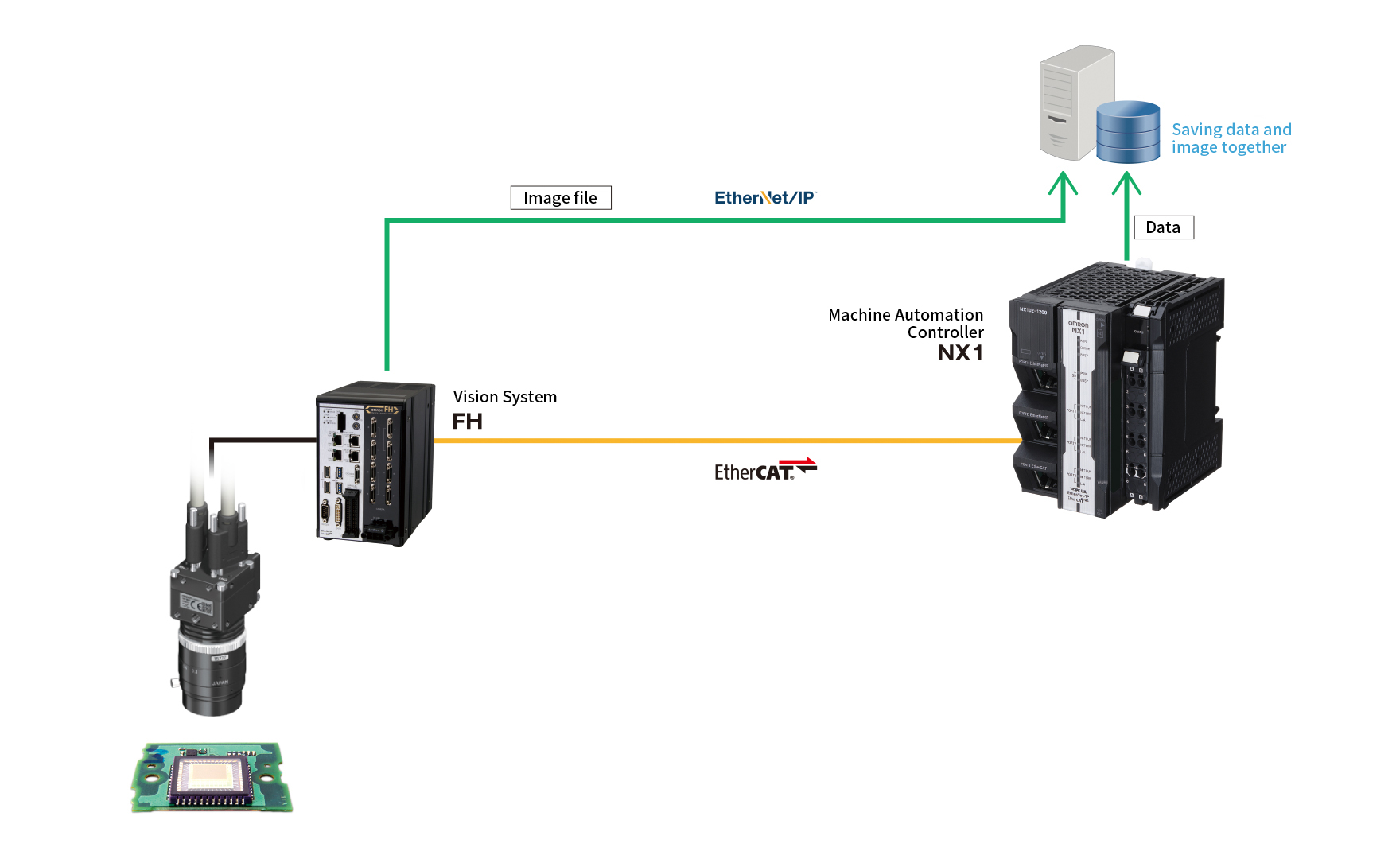

Appearance inspection for ECUs

The FH Vision System and the NX1 Controller are combined to perform appearance inspection for electronic control units (ECUs).

The FH Vision System can:

- Reliably inspect all units for missing parts and incorrect mounting thanks to the MDMC light and the high-speed, high-precision camera.

- Save image and inspection data together when used with the NX1.

Download our product catalog

for more information!

for more information!

NX1 Machine Automation Controller

Download our product catalog

for more information!

for more information!

NX-series NX-HAD401/402

High-speed Analog Input Unit

Photographs are for illustration purposes only and do not represent actual applications.

Images used under license from Shutterstock.com.

The system configurations in this page are for reference purposes only.

Sysmac is a trademark or registered trademark of OMRON Corporation in Japan and other countries for OMRON factory automation products.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

Safety over EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

EtherNet/IP™, CIP Safety™, CompoNet™, and DeviceNet™ are trademarks of ODVA.

OPC and OPC UA are trademarks of the OPC Foundation.

Other company names and product names in this page are the trademarks or registered trademarks of their respective companies.

Microsoft product screen shot(s) reprinted with permission from Microsoft Corporation.

The product photographs and figures that are used in this page may vary somewhat from the actual products.

Images used under license from Shutterstock.com.

The system configurations in this page are for reference purposes only.

Sysmac is a trademark or registered trademark of OMRON Corporation in Japan and other countries for OMRON factory automation products.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

Safety over EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

EtherNet/IP™, CIP Safety™, CompoNet™, and DeviceNet™ are trademarks of ODVA.

OPC and OPC UA are trademarks of the OPC Foundation.

Other company names and product names in this page are the trademarks or registered trademarks of their respective companies.

Microsoft product screen shot(s) reprinted with permission from Microsoft Corporation.

The product photographs and figures that are used in this page may vary somewhat from the actual products.