Retrofittable

IoT for existing production lines

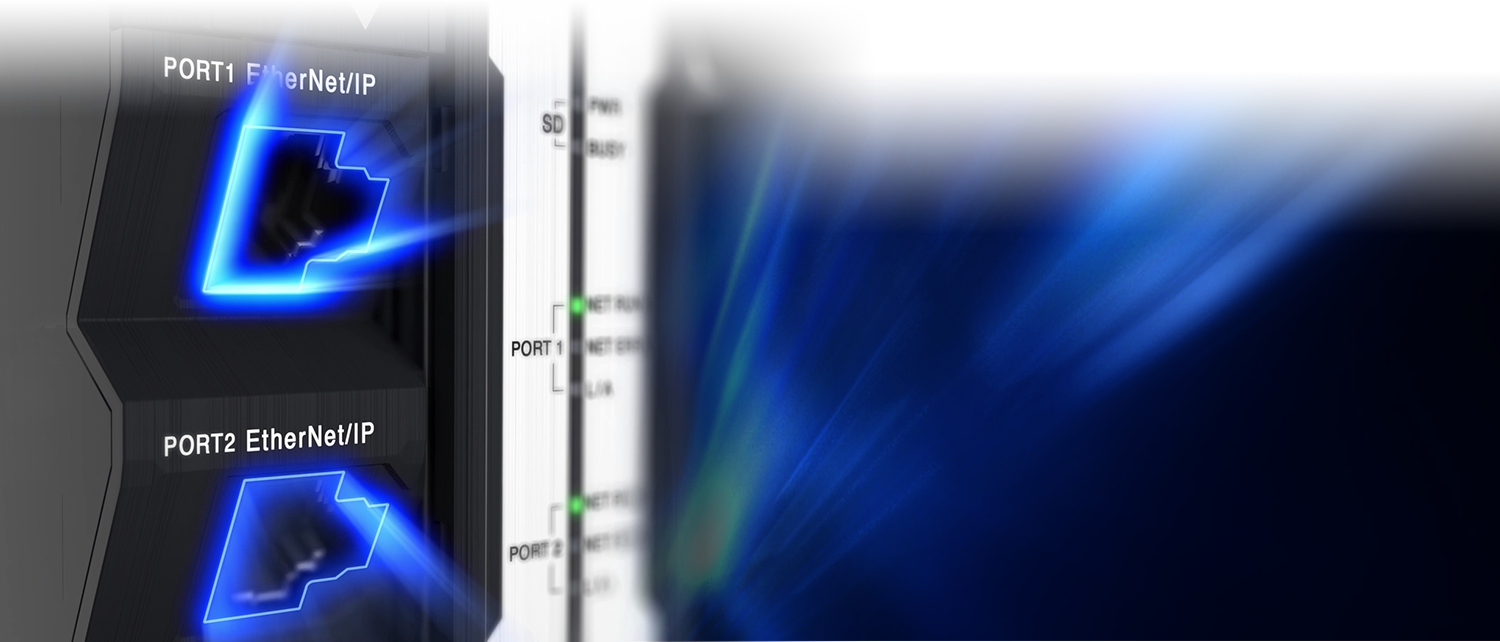

3 built-in industrial Ethernet ports

Connect to existing networks via

2 EtherNet/IP ports and 1 EtherCAT port.

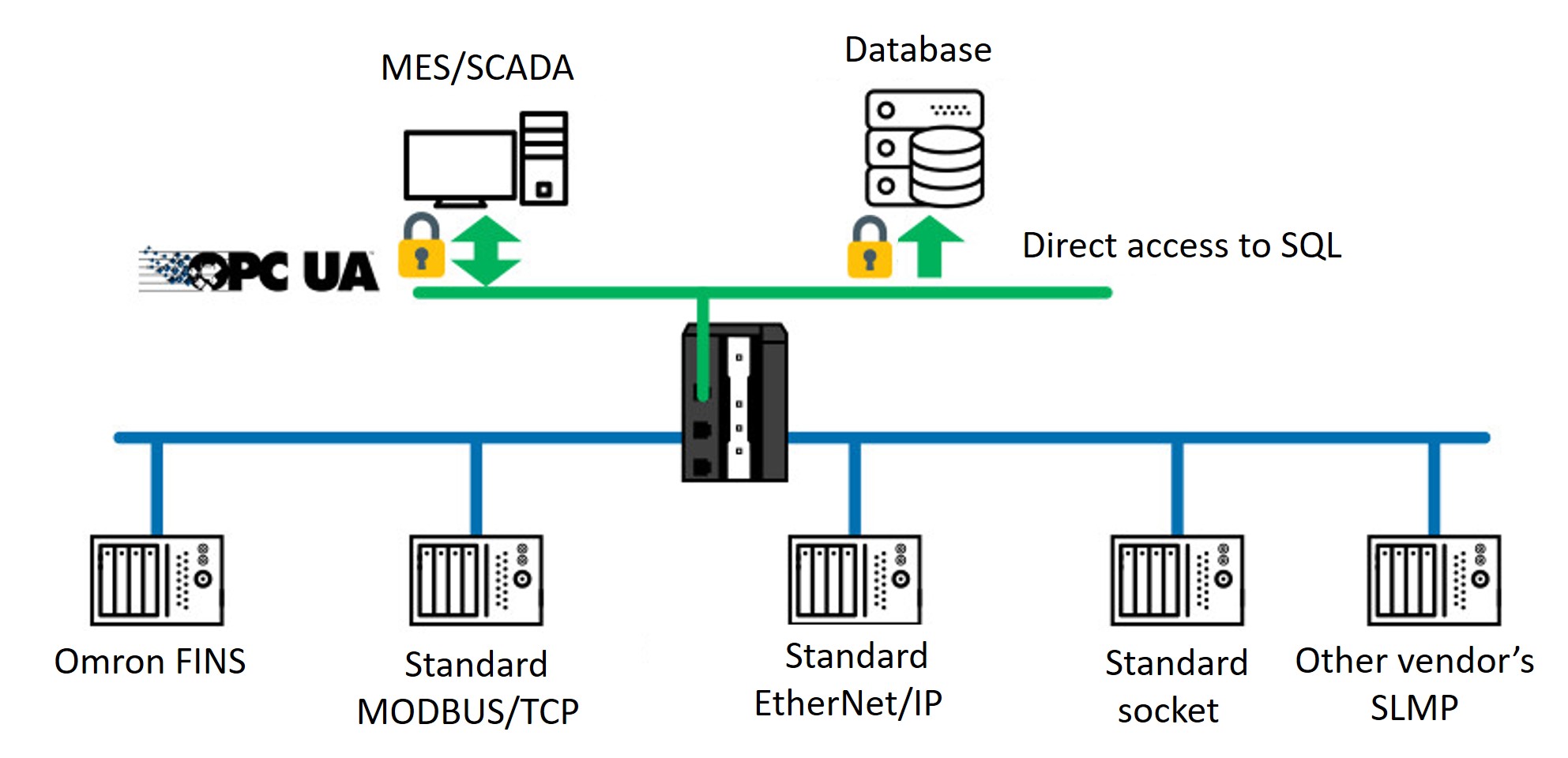

Supports various networks

OPC UA and SLMP certified NX1 ensures

secure connections to existing networks.

What is OPC UA?

What is OPC UA?OPC Unified Architecture (OPC UA), also known as IEC 62541, is an open industrial communication protocol that enables secure and reliable data exchange between products from different vendors and across operating systems.

OPC UA is listed as a recommendation for the communication technology in Reference Architecture Model Industrie 4.0 (RAMI 4.0), which has attracted interest worldwide.

In addition, this standard is integrated with the IEC 61131-3 PLC programming standard to reliably exchange field data from machines to IT systems like MES or ERP, serving as a basis for the packaging standard PackML (ANSI/ISA-TR88) and the standard for exchange of data between injection molding machines (EUROMAP 77).

Since the adoption of this open standard is increasing across the world, we are implementing OPC UA functionality as a standard feature of our NX102/NJ501 Machine Automation Controller. We are contributing to the diffusion of the industrial IoT standard, providing a bridge between industrial automation and information technology.

CPU, power supply,

and Ethernet ports

in slim housing!

Real-time

-

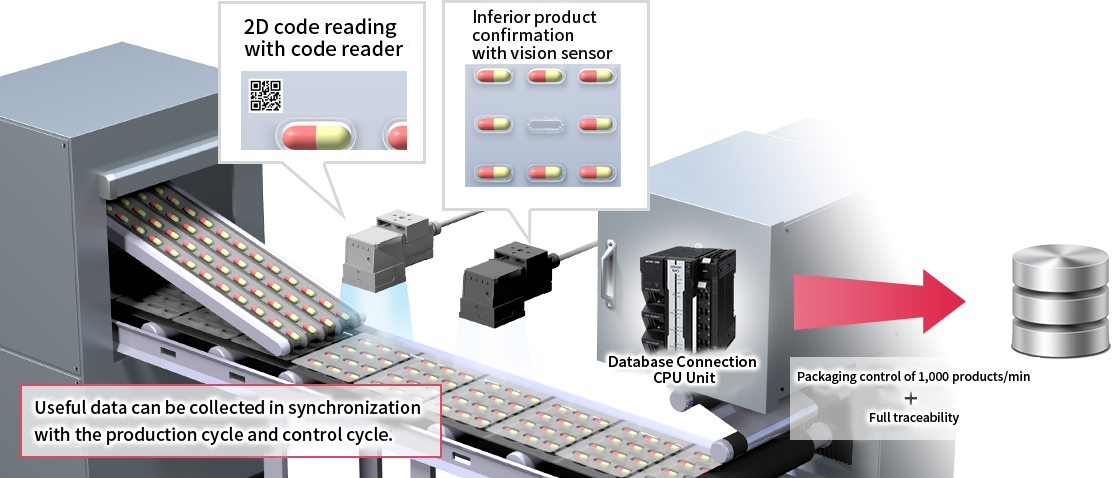

Collection of useful production data

Real-time full traceability

The NX1 can verify 1,000 products per minute (approximately 60 ms per product), enabling traceability of all products without increasing the production cycle time.

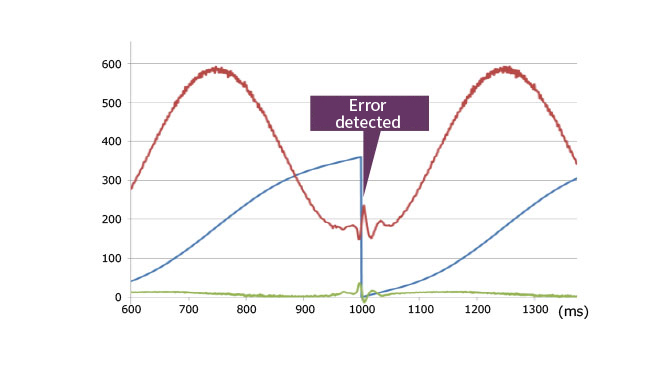

Fast data collection for predictive maintenance

Synchronized data can be stored in a database within the same fixed cycle time of 1 ms, allowing you to understand machine behavior more accurately.

Seamless

Integration of control and information

Based on our long experience,

we bring IoT to production sites using the controller that integrates control and information.

A key element is the use of a multicore processor.

Multicore processor

The NX1 maximizes the multicore processor’s performance to control a machine and utilize data at the same time without compromising control performance.

This enables a single controller to provide

full product traceability during motion control.

Application case study

Food manufacturer

Improve accuracy of liquid filling quantity and collect filling quantity data

| Problem | The quantity of liquid food filled in bottles is inconsistent. If the filling quantity is more than the specified quantity, it can lead to company’s loss. If less than the specified quantity, it can lead to complaints from consumers. |

|---|---|

| Request | To manage production records, filling quantities need to be written into a database without affecting control of the filling process. Monitoring uptime across the production line will be required in the future. |

- Benefit

- The NX1 Controller combined with the NX-RS Load Cell Input Unit can write the filling quantity to the database using database direct connection functionality while controlling filling at high speeds with high precision. This enables production log management. Its OPC UA functionality can be used for information utilization for the entire production line in the future.

for more information!

NX1 Machine Automation Controller

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

Safety over EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

EtherNet/IP™, CIP Safety™, CompoNet™, and DeviceNet™ are trademarks of ODVA.

OPC and OPC UA are trademarks of the OPC Foundation.

Other company names and product names in this page are the trademarks or registered trademarks of their respective companies.

Microsoft product screen shot(s) reprinted with permission from Microsoft Corporation.

The product photographs and figures that are used in this page may vary somewhat from the actual products.