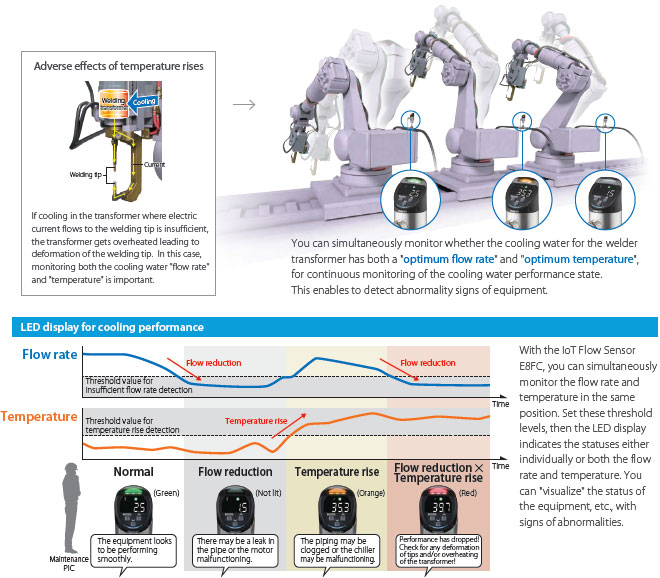

• If the cooling water temperature rises, the welding tip or welding transformer cannot be sufficiently cooled.

• If the welding tip gets overheated and deformed, welding defects occur.

• The welding transformer gets overheated, and the equipment suddenly stops.

• You cannot detect a cooling water temperature rise by monitoring the flow rate alone.

E8FC

IoT Flow Sensors

Detect signs of abnormalities in cooling water, water-soluble coolant, and water-insoluble oil by simultaneous measurement of “flow rate + temperature”

- Features

- Lineup

- Specifications

- Dimensions

- Catalog

last update: August 1, 2022

Prevents sudden stops and molding defects due to cooling abnormalities

Welding machine

Problems

[Deformed welding tips and overheated transformers due to cooling performance degradation]

Solution from OMRON

You can detect signs even before welding tip deformation or sudden stops occur

Molding machine

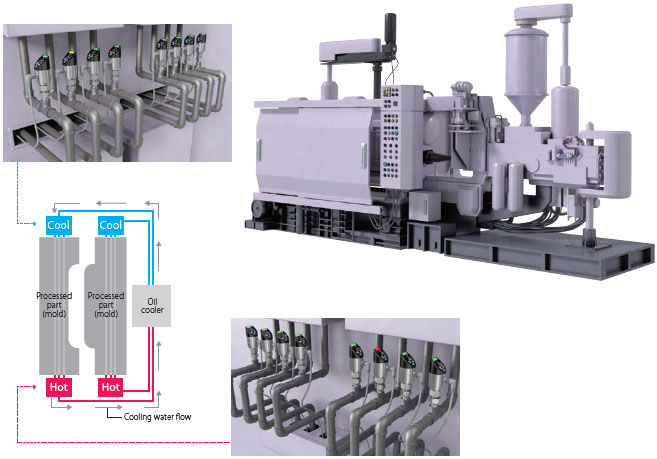

Problems

[Molding defects due to cooling performance degradation]

• Even if the amount of cooling water is adequate, a rise in water temperature leads to a drop in cooling performance.

• If the cooling performance declines, the processed part on the mold cannot be adequately cooled, resulting in deformation, voids, or other molding defects.

• You cannot detect a cooling water temperature rise by monitoring the flow rate alone.

Solution from OMRON

You can detect signs of cooling performance degradation even before occurrence of molding defects.

Monitor the "flow rate" and "temperature changes" in the same position, and quantify the optimum ranges for flow rate and temperature. You can detect signs of cooling performance degradation without relying on the experience or skills of maintenance personnel.

In addition, by mounting sensors on multiple pipes, you can quickly tell from the sensor LEDs what abnormality has occurred, in which pipe.

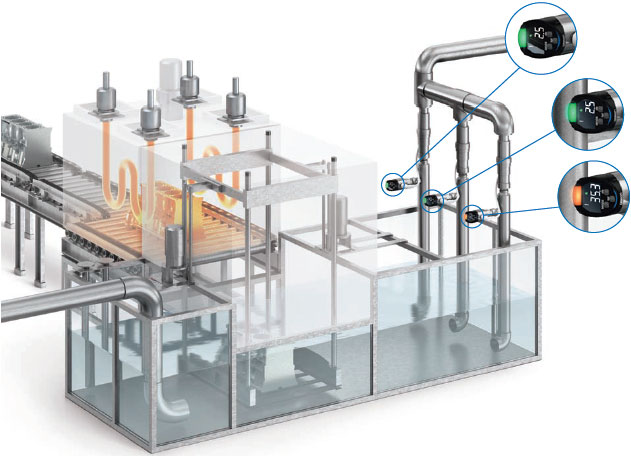

Prevents insufficient strength of parts due to cooling abnormalities

Carburizing furnace

Problems

[Parts strength defects due to cooling performance degradation]

• The requirement for the parts strength is stricter than before, which makes the stable cooling performance of the carburizing furnace more important.

• To meet this requirement, not only the currently measured cooling water flow rate but also the temperature must be maintained to be constant.

• Additional installation of a thermometer incurs high plumbing costs.

Solution from OMRON

You can optimize cooling performance by monitoring flow rate and temperature to enhance strength of parts

You can simultaneously monitor cooling water temperature and flow rate to maintain and control the ideal cooling performance. This ensures consistent finish and raises the strength level of parts. Machines can be developed to enhance strength by leveraging cooling performance data.

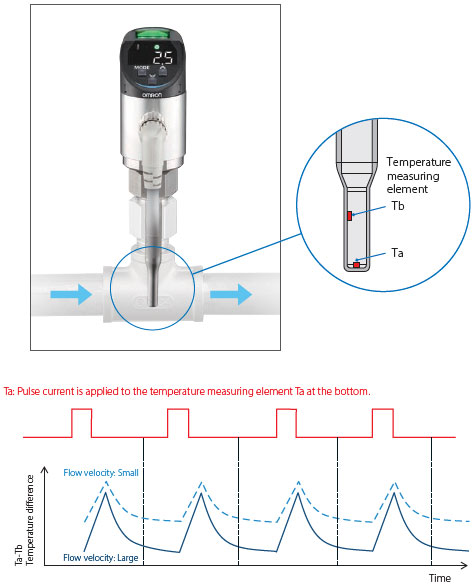

Multi-sensing technology

[Flow rate]

Uses the "Thermal flow rate measurement algorithm".

The sensor calculates first the flow velocity by measuring how fast the fluid cools the heated temperature measuring element Ta, and then the flow rate based on the pipe diameter.

[Temp.]

The temperature measuring element Tb directly measures fluid temperature.

Notifications of changes in the cooling water or hydraulic oil states are easy to understand

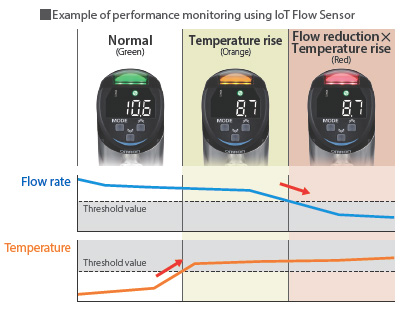

You can see the cause of the abnormality Multi-sensing display [Patent pending]*1

The sensor judges by monitoring "Flow rate + Temperature" and "Pressure + Temperature". Since data outputs to a PLC by the IO-Link communications is possible, it is easy to perform maintenance before entering an abnormal state. For the display colors, you can set 3 patterns, or if combined with Not lit, a total of 4 patterns.

*1. “Patent pending” means that we applied for a patent in Japan, and “Patented” means that we obtained a patent in Japan. (As of July 2022)

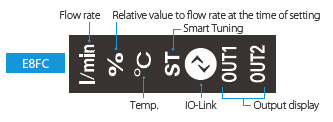

You can see the rate of change with a percentage Relative value display

With the flow rate at the time of setting as 100%, you can relatively measure the change in flow rate value. Smart Tuning function is convenient for cases where optimum value management of absolute values is difficult, such as when the operating environment is changing, and liquid types are changing, etc.

Easy to understand Display by unit

Converts to physical quantity units for display.

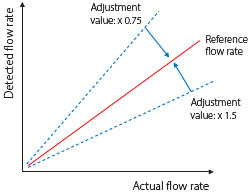

Adjustable to reference flow rate Scaling function

Detected flow rate values can be adjusted to reference flow rates (red line) of the application. This function is useful when detected flow rates deviate from reference values.

Easy to see High luminosity LED display

A high luminosity LED gives good visibility even at the back of equipment or in dark locations.

Even if the sensor is installed in dark locations or at the back of equipment at manufacturing sites, a high luminosity LED enables you to easily read the status. You can immediately tell which sensor is showing signs of abnormalities by the colors of the indicators.

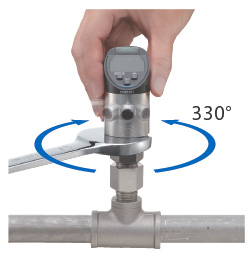

Adjust the angle according to the mounting position

Angle adjustment up to 330°

After fastening to the adapter, you can adjust the angle so that the display is easy to see.

180° reverse display

The display can rotate 180°.

Useful functions to capture equipment status

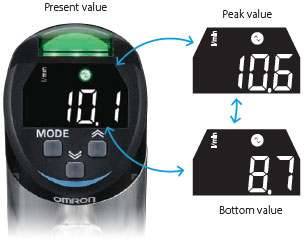

Peak/Bottom Hold function

Data at the moment when an error occurs can be identified even if no one is on site.

NPN/PNP selection

The output polarity can be easily switched with a button, eliminating the need to use different sensors for each polarity.

This means that maintenance stock can be reduced.

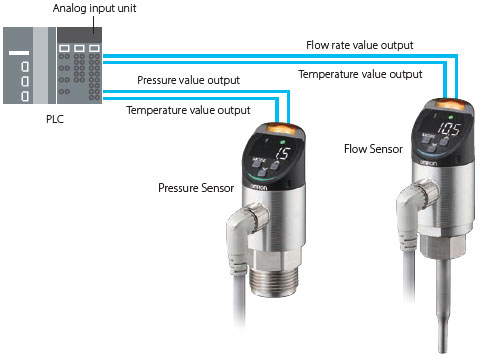

Two-channel analog current output

Both flow rate or pressure values and temperature values can be output as analog currents at the same time, which enables simultaneous monitoring of two physical quantities even in equipment using only analog input devices.

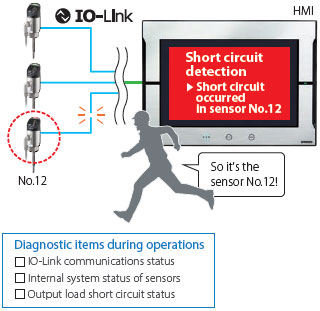

You can also see the sensor status Self-diagnostic outputs

Self-diagnoses the sensor's own status, and autonomously sends notification when signs of a connection error or a malfunction appears.

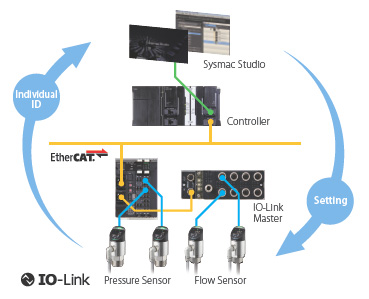

Batch setting from host devices

During maintenance, the settings must be the same conditions as when the product was initially mounted. If you use the IO-Link function, you can perform batch setting from a host device. You can manage by quantifying the adjustment that is performed by skilled personnel to avoid affecting the manufacturing quality.

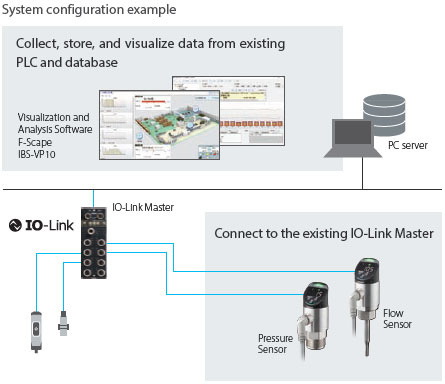

Easy visualization of on-site issues

Data can be easily collected from sensors installed in existing equipment and monitored remotely simply by connecting the sensors to Visualization Software F-Scape that highlights on-site issues.

Building a complex system and programming are no longer required.

Easy to use in various location

Compact and space-saving

You can even mount in narrow spaces with multiple pipes arrayed.

Expanded cable and adapter lineups (sold separately)*

* Use our dedicated adapters. In addition, if there is a possibility of pulsations or vibrations to a Pressure Sensor, we recommend the attachment of a throttle (sold separately).

Easy-to-clean structure

Structure is easily removable from the piping for periodic inspections, etc., and easily cleaned.

Highly durable liquid contact part

last update: August 1, 2022