Why does the adoption of Omron’s NX1 Controller increase in the automotive industry

in Japan, which experiences a major change once in 100 years?

The automotive industry in Japan is undergoing a dramatic change, such as the development of autonomous vehicles and expansion of the EV and other environmentally friendly vehicle market. This change is also known as the major change once in 100 years.

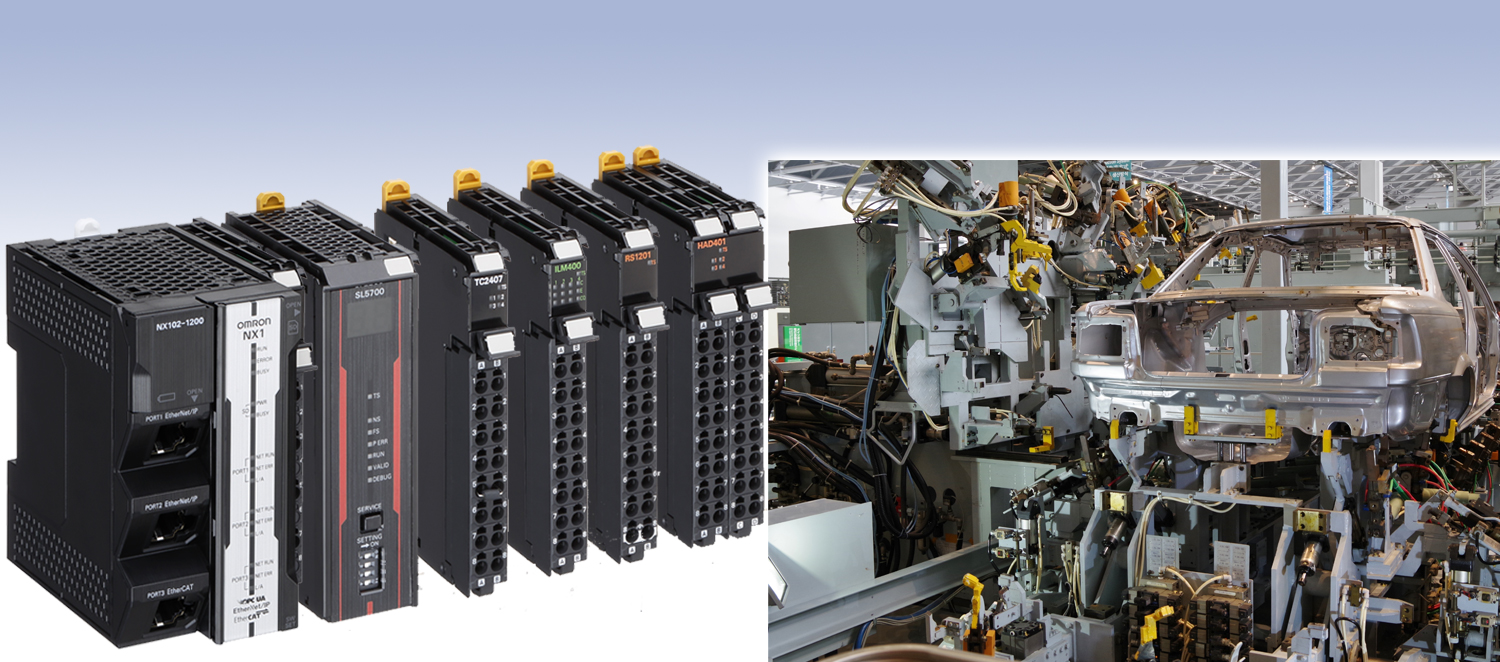

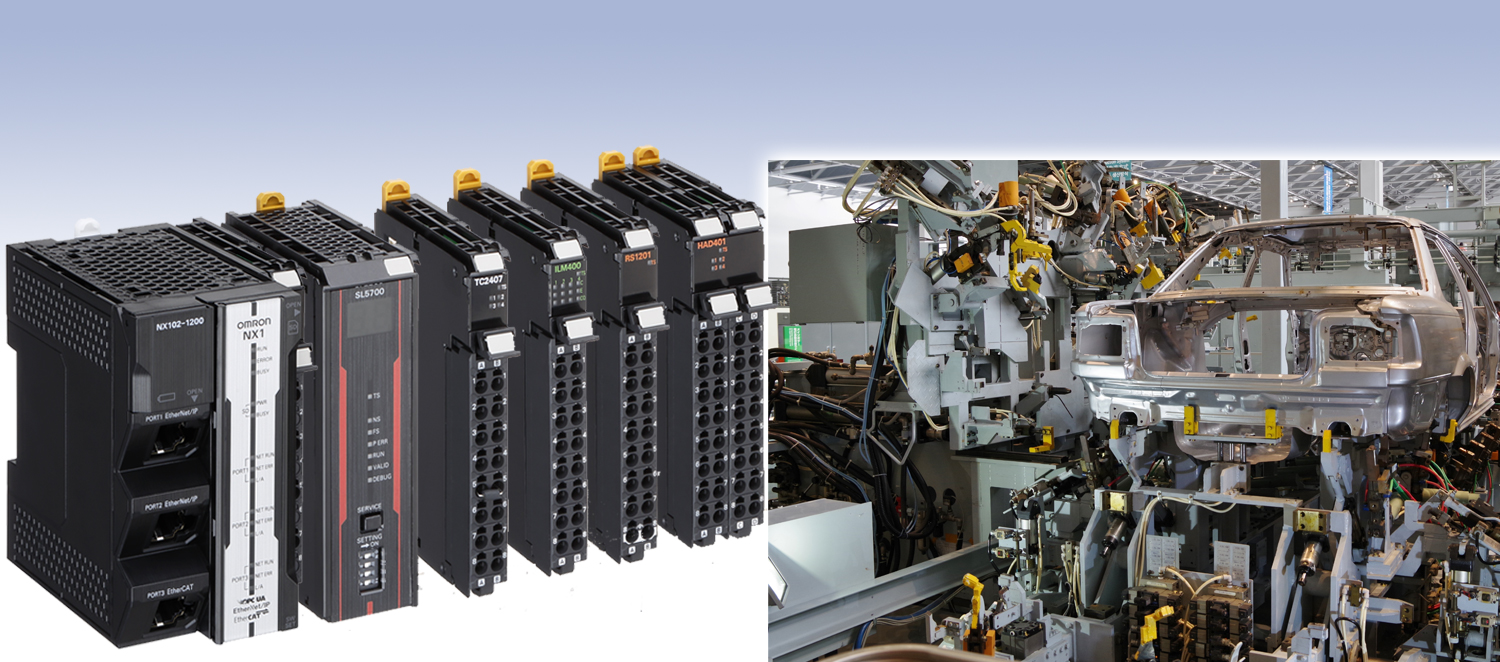

In such circumstances, manufacturers in the automotive industry in Japan started to adopt Omron’s NX1 Machine Automation Controller. Product Manager talks about why NX1 is valued.

Some solutions will also be introduced.

Solutions PDF: Add traceability - Verification and traceability of all automotive parts

The manufacturers in the automotive industry facing the major change adopted NX1 as their standard PLC because of its four features: global open, IoT, advanced architecture, and modularized. I realized that the values, which has been brushed up by NX1 and the basis of controllers Omron has fostered, met the needs of manufacturers in the automotive industry amid the major change.

Now I explain the four features.

The automotive industry is now moving forward with local production and consumption and local sourcing by employing local equipment manufacturers and engineers to produce products near the consuming countries. Factories are built in various countries, mainly in Japan, the United States, and Asia. In this trend, project managers at local factories are concerned that when the technologies used for machines and lines in Japan are deployed across the world, it takes much time to have local equipment manufacturers understand them and to educate engineers at local factories. They need to reduce this time.

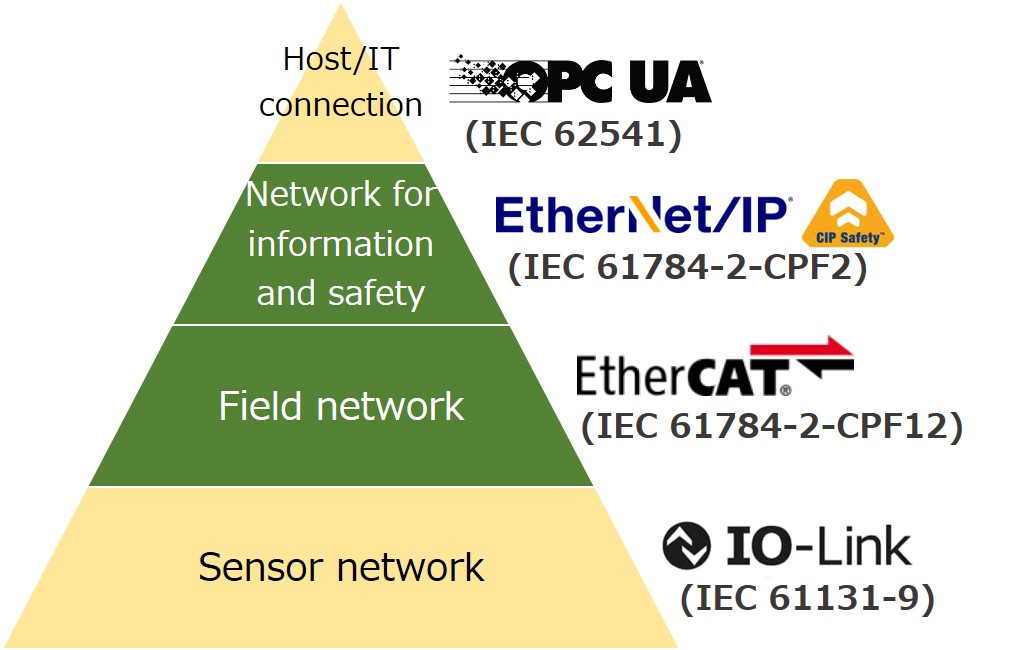

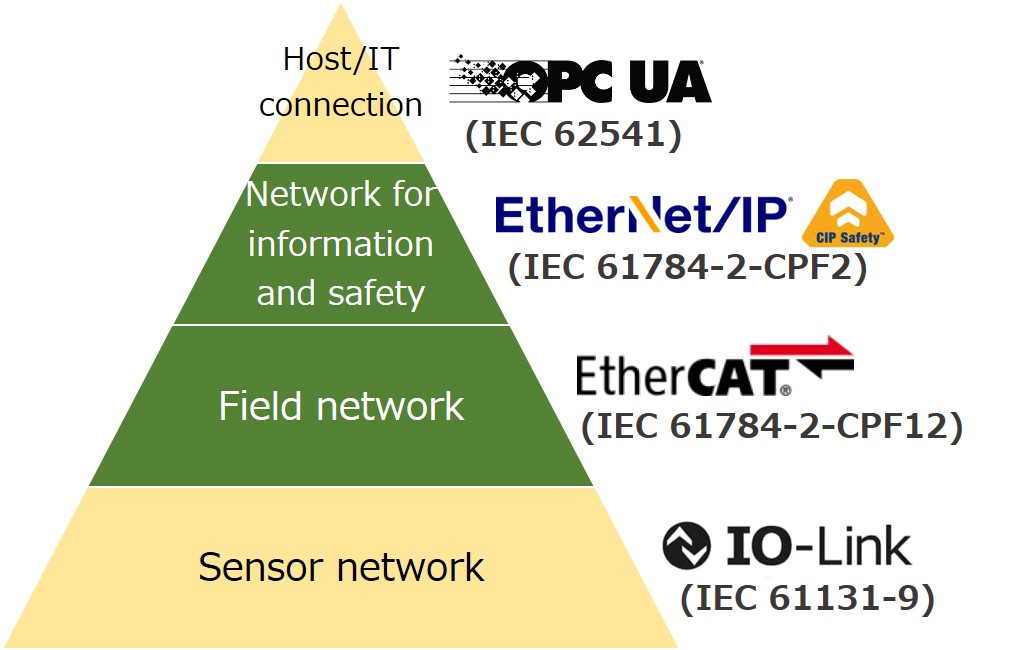

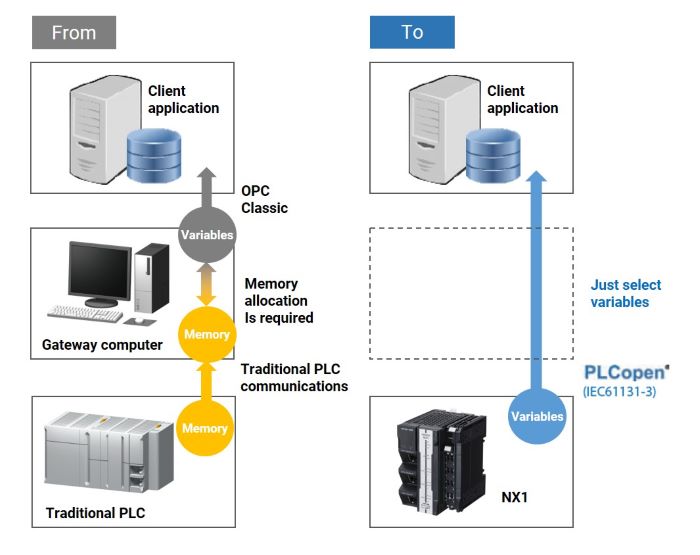

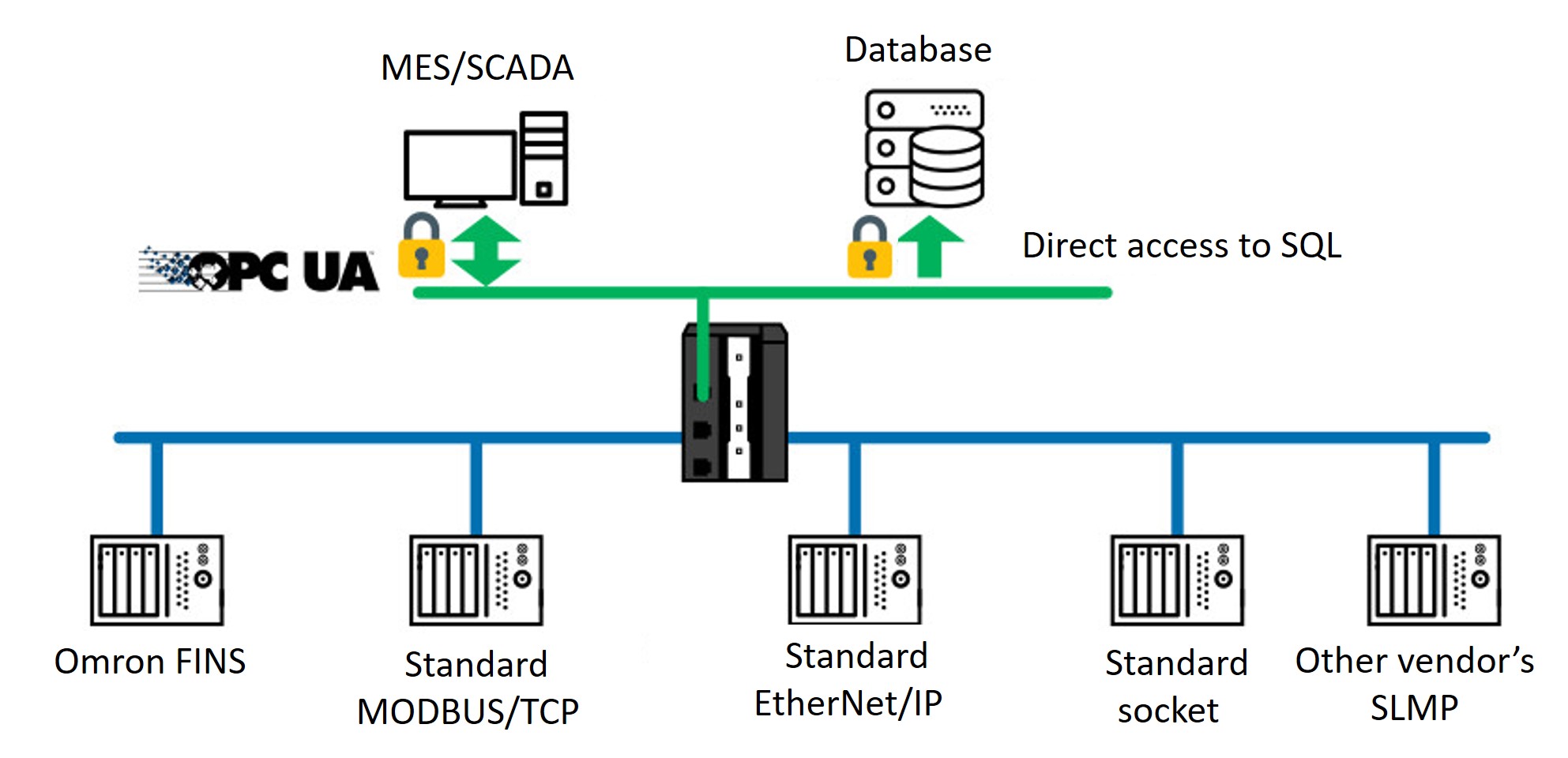

NX1 supports global standard industrial networks, OPU UA, EtherNet/IP™, and EtherCAT®, and complies with the PLC programming standard IEC 61131-3 (PLCopen). This reduces the time required for project members to explain and train engineers in each country. The customer who adopted NX1 appreciated that NX1 made employment and recruitment easier because it eliminated the need for special education for local engineers in each country.

Reference: Trend in global open and certification

The use of global open programming language according to IEC 61131-3 and open industrial networks is crucial to globalization and development of local human resources. READ MORE >

Collecting various information from production machines and lines is needed to improve productivity and comply with quality management standards such as IATF 16949. The customer using NX1 for quality traceability said that the PLC for machine control could be installed quickly without using PC to implement traceability for all parts.

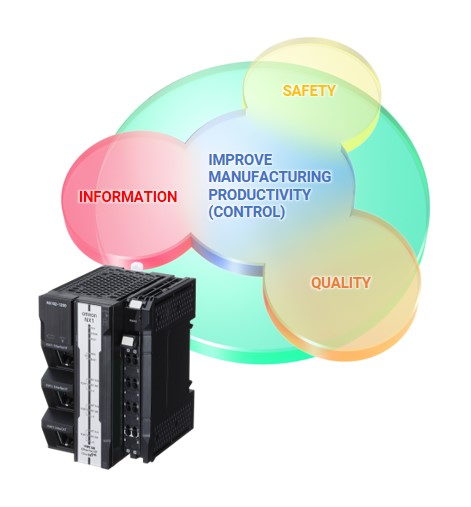

Manufacturing machines require three elements: control, information, and safety. A different controller or PC was used for each element. NX1 can handle control, information, and safety, making design and configuration simple and reducing installation time. One of our customers said, “Safety is essential for manufacturing sites in the automotive industry. The concept to integrate control, information, and safety is excellent.”

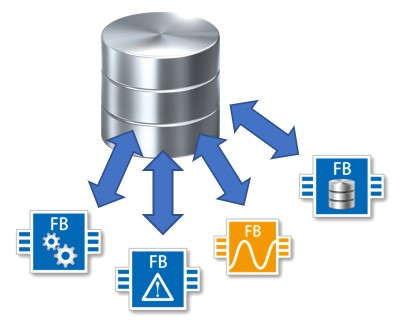

Structured programming to write programs in functional units reduces design time. “It took two weeks to adjust machines to meet our customer’s requirements and retrofit them, but the reuse of modular programs reduced programming time required for adjustment and retrofit to about one day,” a customer said.

The compact design of NX1 is suitable for modular machines and processes.

NX1 is used for not only new machines but also existing machines to improve their functionality. Omron’s engineer visits you to propose the best solution for your application.

Here I introduce some examples of our solutions.

When a PC is connected, problems often occur, and on-site operators cannot handle the PC. We don’t want to use PCs if possible. This is one of problems manufacturers frequently encounter.

NX1 with database connection functionality and OPC UA connectivity can be connected directly to the higher-level system. A system for quality traceability could be constructed quickly by integrating NX1 into the existing machine without adding an PC.

Solutions PDF: Add traceability - Verification and traceability of all automotive parts

To adapt to the change in a safety standard, a customer needed to improve safety of the robots that did not comply with the new standard. Omron’s engineer who is a qualified safety assessor visited their factory and proposed a solution to conform to the safety standard using their existing system.

Solutions PDF: Add safety - Conformance of existing robots to safety standards

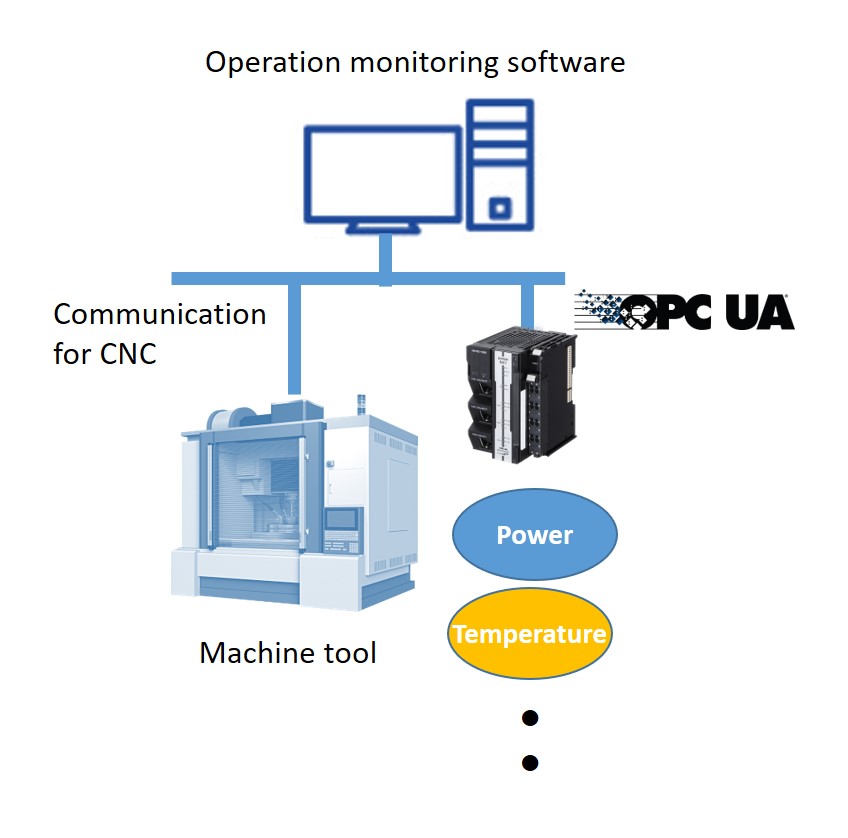

A customer wanted to find improvement points at their manufacturing site by quantifying the operating status of existing machine tools. NX1 supports the international standard OPC UA that enables reliable exchange of information and is recommended for the communication technology for industrie 4.0. They built a visualization system using it. They can easily check the current status including machine uptime, and they are sure that further improvements at their manufacturing site will be made.

Solutions PDF: Add IoT - Operation monitoring of existing machine tools

NX1 can meet various requirements, from new installation to functionality improvement of existing systems. Please consult Omron.

Omron provides the collection of software functional components Sysmac Library including SLMP Communications Library (conforming to Mitsubishi’s CC-Link IE Field SLMP) to connect with Mitsubishi’s Sequencer and other functions to facilitate retrofitting existing machines with NX1. In addition, Omron’s engineers make propositions on the basis of their experience.

Three introduced NX1 solutions can be downloaded in PDF format.