The Data Flow Controller empowers on-site staff to start data utilization on their own, even if they’re unfamiliar with programming languages or control programs.

DX1

Data Flow Controller

An edge controller that provides a simple entry point to data utilization

- Features

- Lineup

- Specifications

- Dimensions

- Catalog

last update: January 26, 2026

A quick and easy start to data utilization, for anyone

Easy connection to existing equipment via Ethernet cable

The Data Flow Controller can be retrofitted easily with Ethernet cables—no need to rewire your existing equipment.

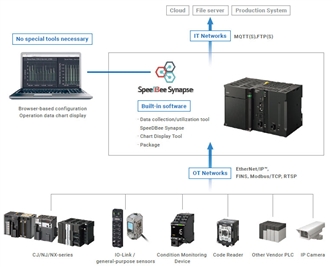

Zero tool installation

SpeeDBee Synapse, a data collection/utilization tool built into the Data Flow Controller, and the Chart Display Tool are both browser-based. They don’t need to be installed to your PC, and can be viewed and configured anytime, anywhere.

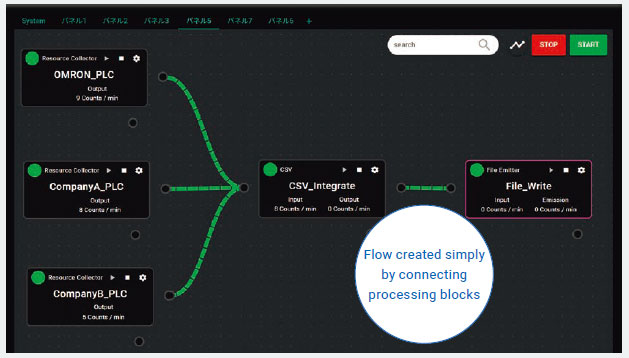

Flow editor that can be used with zero programming (no-code)

The Data Flow Controller’s flow editor lets you create data processes (data flows) just by connecting the processing blocks (components) you need with lines.Processes for collection, analysis, transmission, integration, etc. can be created intuitively, making designing accessible even to those unfamiliar with programming.

Videos for easy setup

We provide tutorial videos for a range of Data Flow Controller operations, from first-time login to troubleshooting—with even more to come.

![]() https://www.fa.omron.co.jp/dx1/video-manual/en/

https://www.fa.omron.co.jp/dx1/video-manual/en/

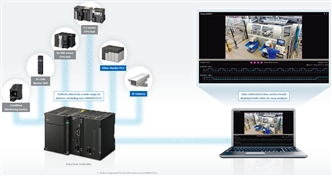

Easy-to-handle time-series data

Data from different devices, including non-OMRON PLCs, can be collected in time-series format.

Data can also be viewed together with corresponding video. This allows you to examine equipment behavior upon issue occurrence, making data analysis and identification easier.

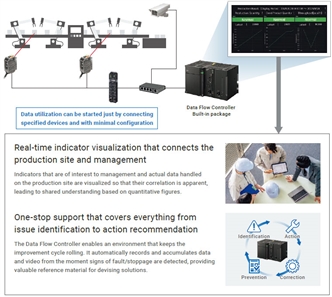

From templates to customization—solutions for every level

To make data utilization easier, the Data Flow Controller has a built-in package, including templates for critical indicators.

It can also be customized for more advanced data utilization that the templates may not cover.

Templates that enable immediate retrieval of critical indicator data

Start your data utilization journey smoothly by simply connecting the specified devices*1 and selecting packages pre-installed to the Data Flow Controller.

*1. For the connected devices of each package, refer to the data sheet of the Data Flow Controller DX1 (Cat. No. V305)

Complex/advanced customization also supported

Customization using PythonTM and C—for connection with PLCs provided by non-OMRON suppliers, complex calculations, communication via unsupported protocols, and other system-specific features are covered.

Effective on their own that can also work together to drive improvement

The Packages helps you track uptime, identify stoppage causes, and make improvements. It coordinates four separate packages to visualize everything from individual equipment and devices to the factory at large along the same timeline, and links KPIs with on-site operations. Each package can also be individually implemented, allowing you to start small according to the specific needs of your production site.

Implementation with zero equipment downtime

The Data Flow Controller can be retrofitted without stopping your equipment, allowing you to start data utilization smoothly and without impacting productivity.

Retrofit support even for equipment using non-OMRON PLCs

The Data Flow Controller supports an extensive array of communication methods and requires no replacement of devices or control programs. This means that you can start data utilization with your equipment kept running, even when using a non-OMRON PLC.

Supported PLCs

Mitsubishi Electric Corporation : MELSEC-series

JTEKT Corporation : TOYOPUC-series

KEYENCE CORPORATION : KV-series

Panasonic Industry Co., Ltd. : FP-series

OMRON Corporation : NJ/NX-series, CK-series, CS/CJ/CP-series and NSJ-series

Note: Some of the above models may not be connectable.

Contact your Omron representative for details.

Smooth transition from pre-implementation evaluation to rollout

You can get a feel of the Data Flow Controller before actually purchasing it, by trying out its trial version. Support is available at locations across the world, allowing you to embark on your data utilization journey with confidence.

Key advantages of the Data Flow Controller

The Data Flow Controller provides a simple path to production site data utilization, through its built-in software that requires no special tools and broad support of networks that integrate IT and OT.

last update: January 26, 2026