Question

The sensor is operating normally, but the K3NR Digital Panel Indicator's display is not changing. Why is this happening?

Answer

The following three causes are most likely.

Cause 1. The sensor is wired incorrectly.

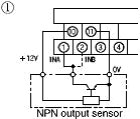

When using a 3-wire sensor, connect to terminal 10 (power supply +), terminal 11 (power supply −), and terminal 1 (output).

When using a 2-wire sensor (NPN open-collector output), connect to terminal 11 (power supply −) and terminal 1 (output).

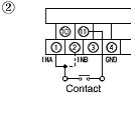

When using a relay contact or Solid-state Relay (NPN open-collector output), connect to terminal 11 (power supply −) and terminal 1 (output).

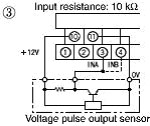

When using a sensor's voltage pulse output or a Mitsubishi inverter's FM output terminal, connect to terminal 3 (+ side) and terminal 11 (power supply −).

Note:The FM output from a Mitsubishi inverter is a voltage pulse output.

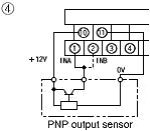

| NB: NPN input or voltage pulse input connections | PB: PNP input connection | ||

| NPN open-collector output or NPN DC 2-wire output | Contact output | Voltage output | PNP open-collector output |

When using an NPN DC 2-wire sensor, input +V to terminal 1 and -V to terminal 11. |  When shorted, about 12 V and 13 mA (nominal) will flow. |  |  With using a voltage pulse input that is not from a 3-wire sensor, input +V to terminal 3 and -V to terminal 11. |

Cause 2: The sensor's capacity does not match the K3NR.

Check the sensor's leakage current. When connecting to a K3NR, select a sensor with an OFF leakage current of 1.5 mA max.

It is especially important to have an appropriate leakage current when using a 2-wire sensor or Solid-state Relay.

Cause 3: The auto-zero time setting is too short.

The K3NR calculates the predicted pulse interval in order to predict when the next pulse will be input. If a pulse input is not received within a certain time, it is necessary to indicate that rotation has stopped (set display value to 0), and the auto-zero time specifies how long the K3NR will wait before determining that rotation has stopped. If this auto-zero time is set to a value shorter than the pulse interval, the display is forcibly set to zero.

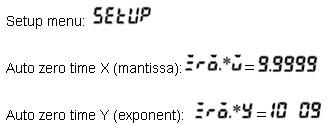

First, restore the auto-zero time to its default setting (X = 9.9999, and Y = 10 E 9).

If it is verified that measurements can be taken, set the auto-zero time to a value appropriate for your application.