Materializing quantitative solder joint inspection, whilst minimizing the risks of overlooked defects defined by the quality criteria, and contributing to a vertical startup.

VT-S730

PCB Inspection System

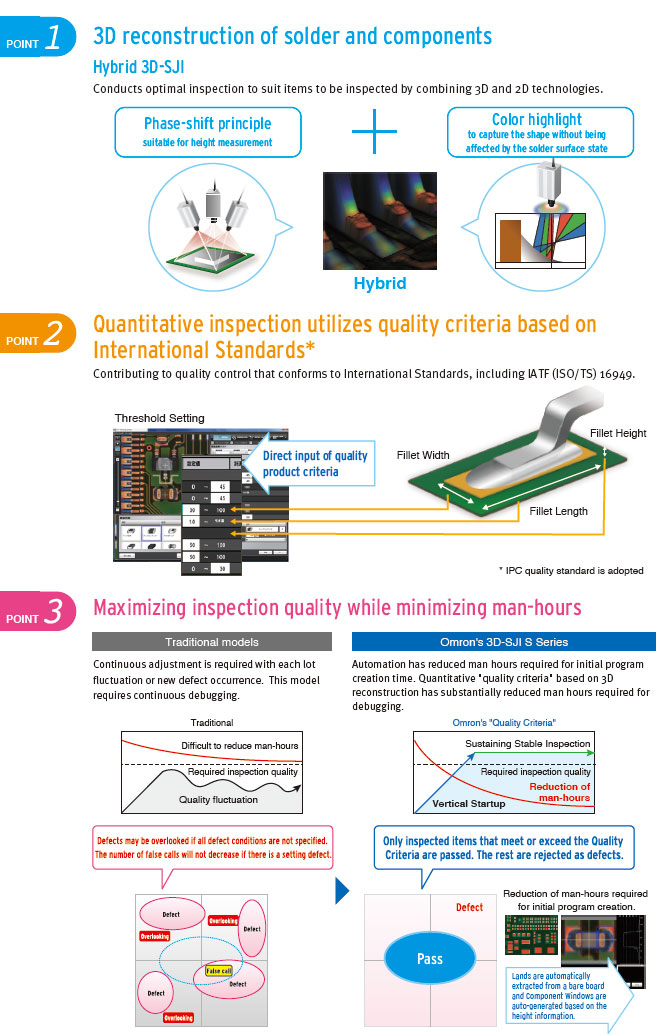

Omron's 3D-SJI (Solder Joint Inspection) Ensuring High-quality Products in an Efficient Manufacturing Environment

- Features

- Lineup

- Specifications

- Dimensions

- Catalog

last update: April 15, 2019

Omron's 3D-SJI (Solder Joint Inspection)

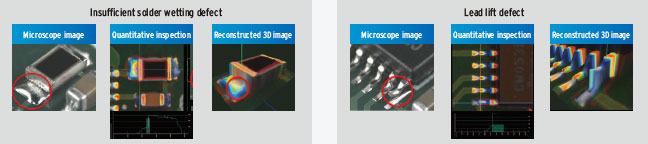

Example Defects

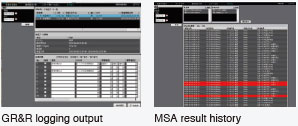

Support for statistical inspection required by IATF (ISO/TS) 16949

Support to quantitatively evaluate measurement for MSA (Measurement System Analysis).

Maintain inspection accuracy by continuously measuring and evaluating accuracy automatically while recording history.

Whole PCB surface inspection

Detecting foreign objects accurately is achieved through combining 3D (height) and 2D (area) measurements on the entire PCB surface. (Lands without solder can be excluded from the inspection)

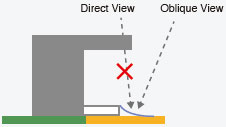

Oblique viewing camera incorporated

Oblique view inspections can be performed on solder joints that are hidden from the direct view camera.

Various Lineup of High-Speed Models

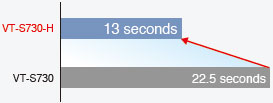

The VT-S730-H incorporates a high-speed image capturing module to substantially reduce the inspection time compared to standard models of the same series.

Comparison of inspection time of Omron's PCB (example)

last update: April 15, 2019