Question

Are there any precautions for the mounting interval, separators, taping, and wavebreaking pipes when mounting Electrodes?

Answer

Note the following Electrode precautions.

1.When cutting an Electrode, be sure to chamfer cut surfaces of the electrode.

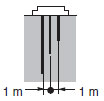

2.Maintain a Clearance Between Electrodes

Maintain sufficient clearance (normally 1 m) between Electrodes in sea water or contaminated water. Use 61F-[]D (or -[]ND) lowsensitivity models if this clearance is difficult to maintain.

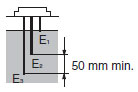

3.Long Ground Electrode

The Electrodes are mounted in sets of three. Connect the shortest Electrode to E1, the medium Electrode to E2 and the longest Electrode to E3. The longest Electrode, E3, must be at least 50 mm longer than the other Electrodes.

4.Consider the Operating Leve

Due to the liquid type and fluctuations in the power supply voltage, the operating level may fluctuate to a small degree from the level at which the liquid surface makes contact with the Electrode tip.

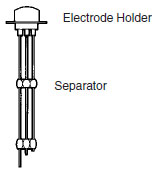

5.Use Separators

If the Electrode length reaches 1 m min., insert Separators at the joint positions to prevent the Electrodes touching each other in the liquid.

6.Do Not Allow Suspended Matter to Short the Electrodes

If suspended matter may short the electrodes, use tubing electrodes. The tubing must be removed at least 100 mm from the bottom end to ensure sufficient conductivity. Do not use a tubing electrode as a ground electrode.

7.Mount Electrodes Vertically

Install the Electrodes vertically to avoid the accumulation of slime which can form an insulating layer on the Electrode surface.

8.Keep Electrodes Clean

Lift the Electrodes and remove the surface film with fine sandpaper about 6 months after installation. Subsequently, repeat this cleaning once or twice per year.

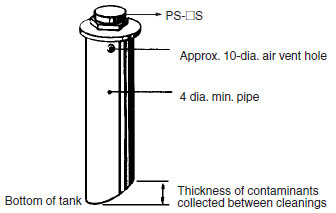

Cleaning is particularly important for Electrodes used in a liquid containing large amounts of dirt or slime, which can build up into an insulating film on the Electrode surface and cause malfunctions. Clean the surface insulating film from Electrodes used in this environment once every three months. Use a pipe, as shown in the diagram below in situations where the water contains large amounts of dirt.

Use a pipe as shown to keep dirt and oil films from the Electrode in situations where the liquid is highly contaminated with dirt and oil, such as sewage holding tanks.

Use a pipe at least 4 inches in diameter.

Cut off the end of the pipe at an angle to clear the estimated amount of contaminants accumulating at the bottom of the tank.

Drill an approximately 10-dia. vent hole at the top of the pipe.

Using an Anti-ripple Pipe:

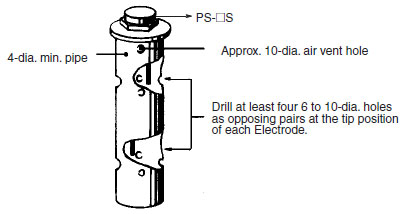

Use an anti-ripple pipe as shown below in cases where large ripples are produced by a rapid fluid flow rate.

Use a pipe at least 4 inches in diameter.

To improve liquid circulation inside the pipe, drill at least four 6 to 10-dia. holes as opposing pairs at the tip position of each Electrode.

Drill an approximately 10-dia. vent hole at the top of the pipe.

Follow the information above with regard to using Electrodes.

Recommended Products

Other Level Switches FAQ

-

Why do the specifications for the High-sensitivity 61F Floatless Level Controller say, "possible to use with 15 kOHM or less, however, this may cause reset failure"?

Why do the specifications for the High-sensitivity 61F Floatless Level Controller say, "possible to use with 15 kOHM or less, however, this may cause reset failure"?

-

Can two 61F Floatless Level Controllers and two Electrode Holders be used in the same tank?

Can two 61F Floatless Level Controllers and two Electrode Holders be used in the same tank?

-

When voltage is applied to 61F Floatless Level Controller, it operates regardless of the actual liquid level. What is the cause of the problem and how can it be corrected?

When voltage is applied to 61F Floatless Level Controller, it operates regardless of the actual liquid level. What is the cause of the problem and how can it be corrected?