Digital Panel Indicators

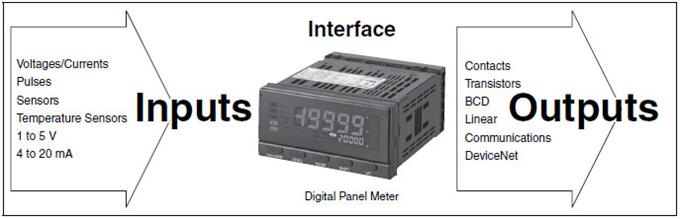

Digital Panel Meters perform digital processing on or conversion and display of voltages, currents, other analog signals, and pulse signals. They can also compare input values to set values, transfer data, and perform other functions.

| Overview |

|

| Principles | Classifications |

| Engineering Data |

|

Overview of Digital Panel Meters

The Role of Digital Panel Meters

Digital Panel Meters digitally process measurement data such as analog signals from linear sensors (including voltages and currents) and pulse signals. It then converts and displays the data. They can also act as interfaces (see note) by performing operations such as comparisons with user-set values, and transmitting data to computers and PLCs

OMRON Digital Panel Meters have good visibility in the field, are easy to use, are waterproof, and conform to international standards. Communications with host computers or programmable controllers have been improved to provide functionality for advanced information systems, such as data collection to increase operating rates and data recording capabilities to provide for implementing measures for PL laws and ISO.

Note:An interface is the boundary between two devices.

Analog Signals

An analog signal is signal that changes continuously.

Types: 4 to 20 mA DC

1 to 5 VDC

0 to 5 VDC

0 to 10 VDC

Infrared Thermosensor

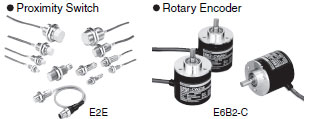

Proximity Sensor or Rotary Encoder

A Wide Range of Voltages/Currents

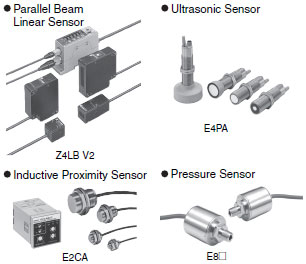

Displacement, Length Measurement, or Linear Output Sensors

Recommended Products

K3HB-X

K3HB-X

A Process Indicator Ideal for Discriminating and Displaying Measurements for Voltage/Current Signals

K3HB-V

K3HB-V

An Ideal Indicator for OK/NG Judgements in Automated and Picking Machines, Measuring Factors such as Pressure, Load, Torque, and Weight Using Load Cell Signal Input.

K3HB-H

K3HB-H

New High-speed, High-precision Temperature Indicator