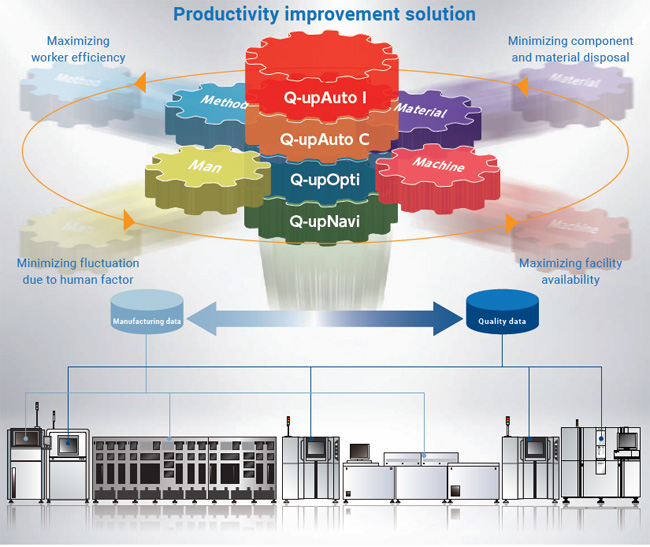

Capturing production 4M data that “affects quality” in real time and supporting

efficient improvement activities based on quality information from inspection equipment

Q-upNavi Series

Productivity improvement support software

Allows real-time capturing of "changes that affect quality" of 4Ms in production fluctuations, and assisting efficient improvement activities.

- Features

- Lineup

- Specifications

- Dimensions

- Catalog

last update: April 22, 2024

Omron supports "Manufacturing without defects".

Q-upAuto feat.Inspection (Abbreviation: Q-upAuto I)

Do you have this problem?

・The operational status of inspection machines cannot be fully grasped, and

countermeasures are delayed, resulting in inspection losses and backtracking.

・The number of personnel in charge is limited and there is no time to debug the inspection programs.

・Routine work such as making production reports takes time.

Q-upAuto I: Improve productivity of inspection machine operation with real-time automatic analysis

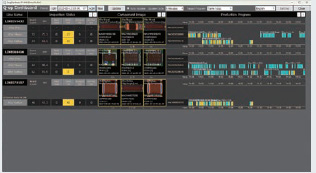

Dashboard

Visualize the operating status of all inspection machines without any skills.

Inspection abnormalities can be noticed in real time, minimizing inspection production loss.

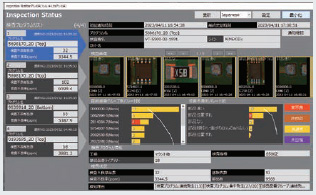

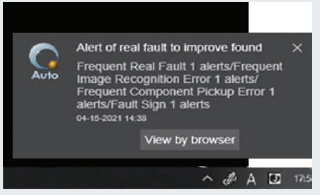

Inspection Status Notification

Automatically analyzes inspection abnormalities and sends push notifications.

Even with limited teaching time, you can quickly find out the part number that needs to be tuned, improving work efficiency.

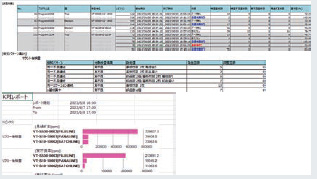

Reporintg

Automatically creates the daily/weekly/monthly reports and changes in pass rate/false call rate/abnormal notification block etc., to confirm improvement effects.

Significant reduction in indirect work man-hours

Performance Comparison

Confirm the improvement effect on pass rate and false-call rate over time for each line or inspection program.

Improving work efficiency

System configuration

Q-upAuto compatible version: S10 series V4.01.00A or higher. S730/530 series V3.03.00C or higher

Q-upAuto feat.Component (Abbreviation: Q-upAuto C)

Do you have this problem?

・We want to produce high-quality products without producing defective products.

・We want to address issues in the mounter process based on quality standards for post-reflow inspection.

・We want to maintain the productivity of mounting process and automate the routine report works.

Q-upAuto C: Supports manufacturing of quality products by linking inspection result data and mounter data in real time

Analysis support (cooperative analysis of inspection data and mounter data)

Using the inspection machine's "defective" judgment information as a starting point, Q-upAuto links it to mounter factors (advance, head, feeder status) and automatically analyze the relationships that occur.

Quality Notification

Receive quality notifications when quality deterioration or abnormalities caused by the mounting process are detected.

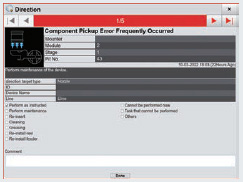

Work order

You can find out the detailed status of the trouble mounter factor (nozzle, header, feeder), making countermeasures more efficient.

Reporting

Automatically creates daily/weekly/monthly reports.

You can check quality results and error records for each mounter factor (nozzle, head, feeder), inspection pass rate and defective rate for each model.

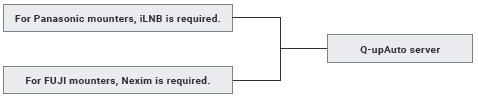

System configuration

It is necessary to purchase an Omron Q-upAuto connection license from Panasonic or FUJI.

Please contact Panasonic or FUJI for details.

Q-upAuto compatible version: S10 series V4.01.00A or higher. S730/530 series V3.03.00C or higher

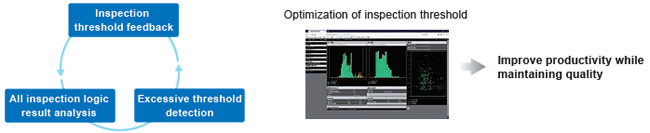

Q-upOpti

“Optimization of process inspection equipment operations”

Optimize the inspection threshold of SPI (post-print inspection machine) and pre-reflow inspection machine based on the quality standards of post-reflow inspection machine.

Q-upNavi

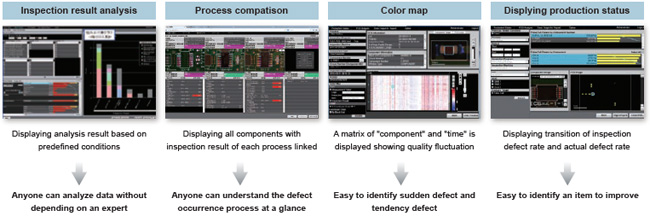

Analyzing quality data (e.g. defect images and inspection result) from inspection systems and productivity information (defect/false call rate).

last update: April 22, 2024