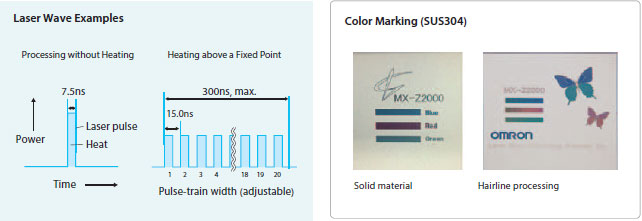

Our exclusive flexible pulse control (up to 1MHz, adjustable 1 - 20 pulses) enables optimum marking and processing for a variety of materials and applications, for a variety of materials and applications, including both heated and non-heated marking/processing, etc. For example, even for small character when thermal effects are problem, Fine marking is possible.

MX-Z2000H-V1 Series

Fiber Laser Marker

Great for either deep or shallow engraving in metals, marking on plastics/resins or plastic films, and for fine processing. Mark anything from electronic parts to automotive parts.

- Features

- Lineup

- Specifications

- Dimensions

- Catalog

last update: December 18, 2023

High Speed and High Quality in a Wide Variety of Applications Marking Flexibility

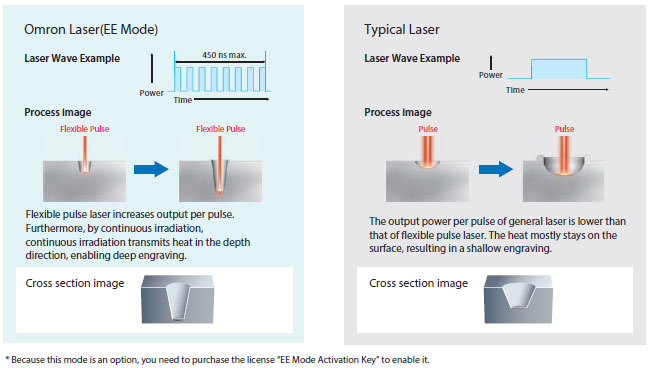

Two Operating Modes Provide Fine Detail to Deep Engraving

Standard Mode

Optional EE Mode (Energy Enhanced Mode)

Deep engraving of metal, rough polishing, and other energy-intense processing become possible with an expanded and enhanced flexible pulse control, which provides pulse streams of up to 30 pulses.

For example, deep engraving suitable for camera reading is possible even after heating process.

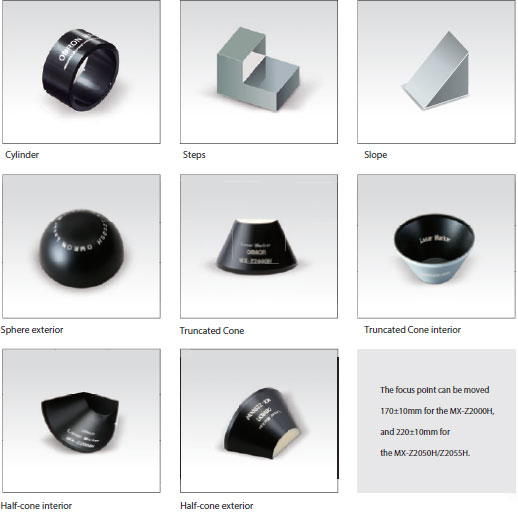

Marking 3D Objects Is Simple Even on Cones and Spheres

High-precision Z-axis Flexibility

Clean marking is now possible for 3D surfaces, such as stepped, sloped, curved, conical and spherical surfaces without any additional software.

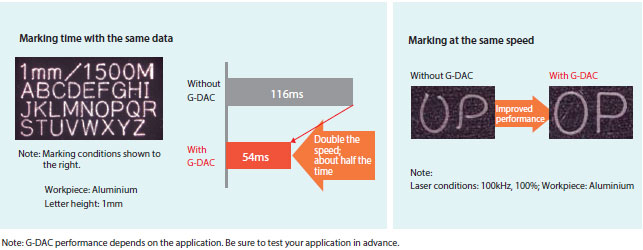

Mark Clearly and Cleanly Even at High Speed

[G-DAC]

G-DAC stands for the OMRON-developed Galvano Dynamic Acceleration Control.

The G-DAC feature adjusts the laser marking speed for optimum performance, based on the marking details.

This speed flexibility enables high-speed, clean marking.

With/Without G-DAC

Enhanced Functionality Improves Productivity Connectivity & Traceability

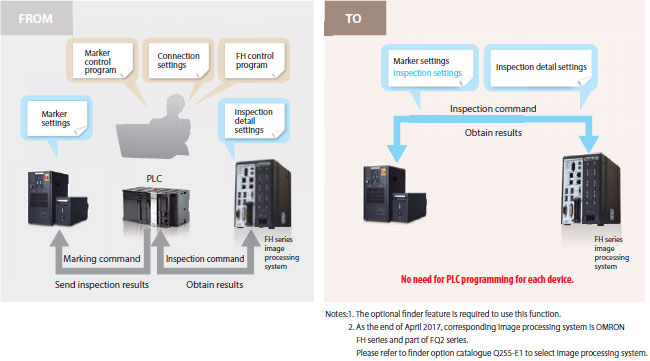

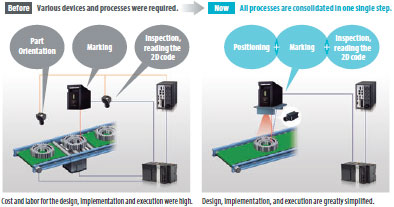

Position-correction without the need of a PLC

Direct Finder Link

The MX-Z2000H series enables direct connectivity between the image processing system and the laser marker that traditionally required PLC processing . This means, there is no need for a PLC to do the linking between the vision system and the laser marker.

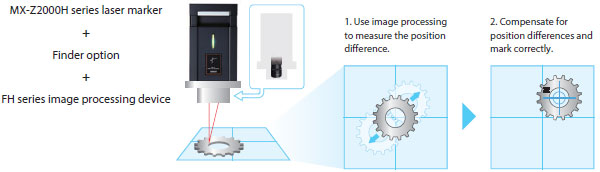

Example Application

To mark a product in the same area everytime, an image processing system measures the position reference, transfers the position coordinates and the laser marker adjusts itself to mark in the correct place. After the laser marking is completed, the image processing system can also read a 2D code or any other inspection of the data or images just marked on the product.

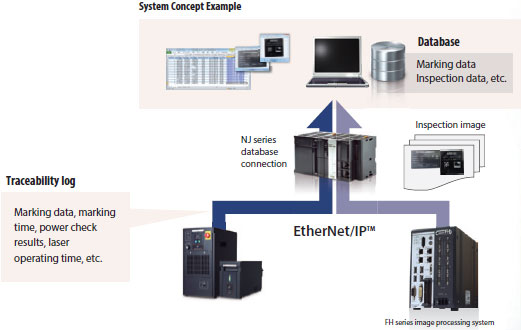

Easily Configure a Traceability System

Traceability Log

Archive marking data, and other data to a log, etc. Simplify both traceability and preventive maintenance.

Smoothly Integrate External Control

EtherNet/IP™ Compatibility

The MX-Z2000H series is compatible with various kinds of external control.

Built-in I/O connections, RS-232C, Ethernet, and EtherNet/IP™ simplify programming to control the system from a PLC.

*Please check the user's manual before using available functions and commands.

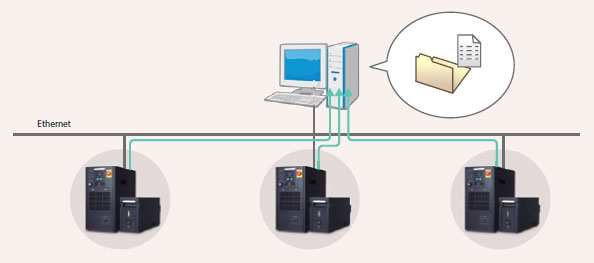

Marking for Small Lots with Multiple Variants

Data can be shared with external storage

The MX-Z2000H series can access the marking data that is stored on an Ethernet server to keep up with the tremendous amount of data used for multi-variant, small lot productions. This simplifies the switching of marking data for each variant.

Withstands Severe Conditions and Meets International Standards Durability/Safety

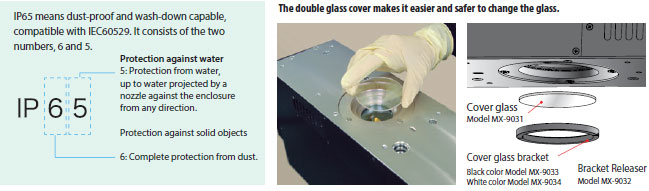

Stable Operation Even in Dusty/Wet Environments

Durable IP65 Head

The laser head (where the laser light is emitted) has a double glass cover to keep dust and moisture away and ensure air-tightness.

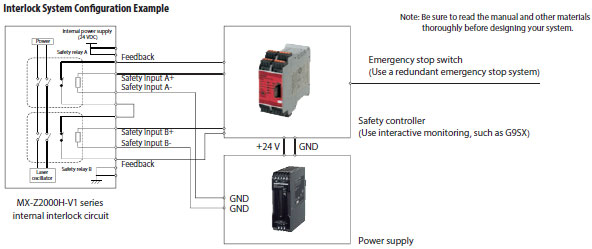

Meets Safety Requirements and Standards

[NEW] Built-in Safety Relay Circuit

When building a machine to meet the ISO 13849-1 (JIS-B9705-1) criteria, you have to provide safety measures for the total machine in which the laser marker is installed. The MX-Z2000H series has 2 safety relays in the controller, and sending an emergency stop signal from an external controller to the interlock terminals will absolutely stop the power supply to the laser. The safety relays installed on the back of the controller can be easily replaced in case of failure.

The laser beam can be emitted within 1 second after returning from laser shutdown by Omron's original fiber laser system.

Meets International Standards and Regulations

The laser markers meet each standard and regulation. They can now be used internationally.

Note: For details about exact countries and areas, contact your local OMRON representative.

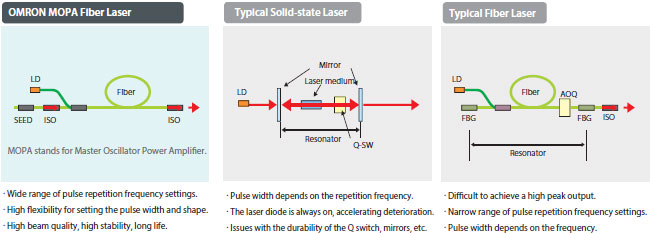

OMRON's Fiber Lasers

All-fiber Lasers Provide High Quality, High Stability, Long Life

MOPA Fiber Laser

Typical solid-state lasers use mirrors to resonate and amplify the laser, and then Q-switching to output the laser. However, this approach makes it difficult to achieve a high quality and flexible laser. It also leaves something to be desired in the areas of reliability and durability. OMRON has achieved high quality, high stability, long life and flexibility by eliminating the resonator configuration and using the MOPA approach.

High Beam Quality

The closer the beam is to a perfect circle, the higher the quality of the laser.

OMRON lasers have a very round, high quality beam, as shown to the right.

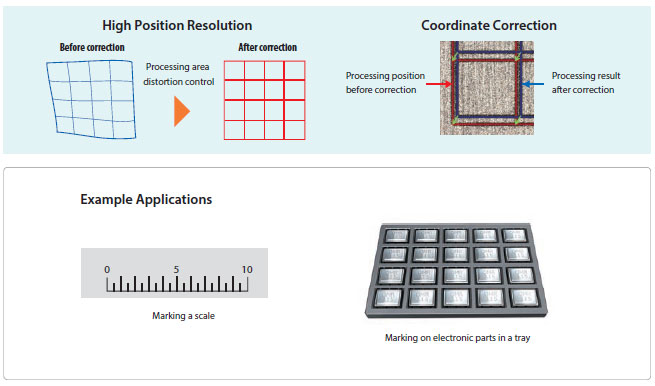

Corrects for Lens Distortion

High Position Resolution/Coordinate Correction

Precision positioning is now possible for fine detail, and processing area distortion is minimized.

Coordinate correction is provided to eliminate errors based on installation.

Operation Flexibility Increases Throughput With Less Effort

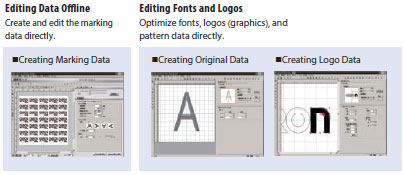

Edit the Marking Data Directly on the Laser Marker

Editing Data

There is no need to buy separate editing software, or a computer to edit data. Data editing functionality is built right into the laser marker itself, simplifying the process.

Offline Editing Software is Also Standard

You can also use a separate computer if you choose, to create and edit the print data, including graphics, with the same functionality as is built into the laser marker.

Simplifying Positioning and Other Floor Work

Optional Features

Finder (Vision Attachment)

The Finder feature enables visual positioning of small parts for marking or processing, as well as automated positioning and inspection with a vision system.

This simplifies the system configuration, reducing processes, cycle time, and costs.

Please refer to the catalogue Q255-E1

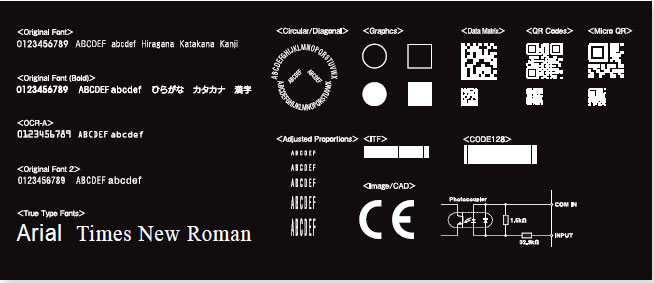

Laser Marking Samples

last update: December 18, 2023