3. Activities of OPC UA (1)

Collaboration

In the previous two articles, we have explained that OPC UA aims for the industrial interoperability standard through three values: Connected, Communicated, Secured.

The OPC UA technology for the industrial interoperability was published as IEC 62541. Software development kits and sample applications to support the development of products for OPC UA are provided as open source.

To enable interoperability, OPC UA is focusing on two activities: Collaboration and Compliance.

This article talks about Collaboration.

Collaboration

Wikipedia defines collaboration as “the process of two or more people or organizations working together to complete a task or achieve a goal”. (From Wikipedia) The OPC Foundation takes an active part in “working together” with other organizations “to complete a task or achieve a goal” of OPC UA. It is necessary to cooperate and work with various organizations using various technologies to enable true interoperability and deliver the values to many people - this activity is Collaboration.

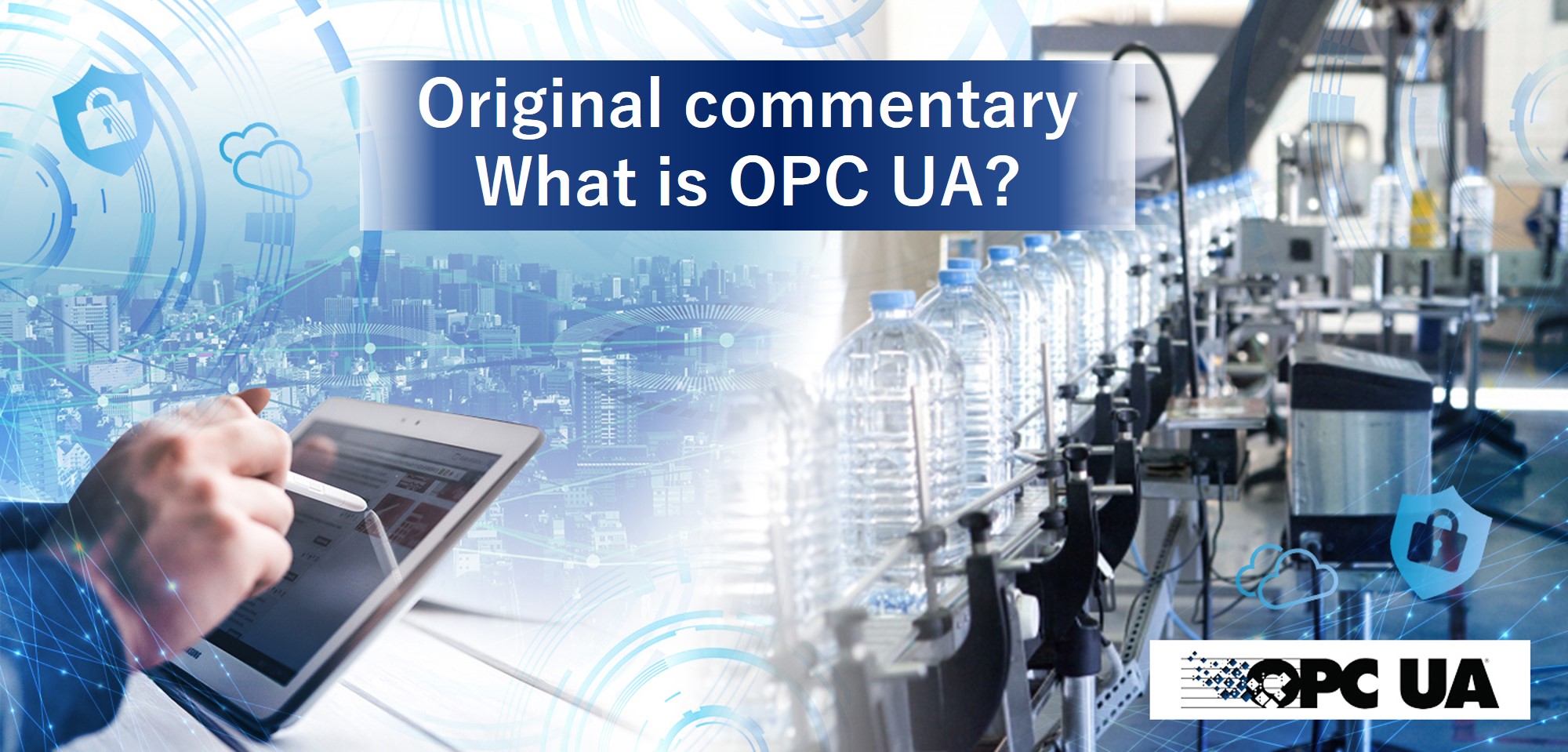

Markets and groups from various industries adopting OPC UA develop

- specifications to apply (companion specifications)

- use cases and guidelines

The examples include OPC UA Companion Specification for PLC “OPC UA Information Model for IEC 61131-3” explained in the previous article.

OPC UA specifications provide “companion information models” that are frames for interoperability. Experts from markets and groups create companion specifications and use cases that are used as contents required for the interoperability in each domain.

As interest in industrial IoT such as Industrie 4.0 has risen, the OPC Foundation has expanded its collaboration activities with more than 50 organizations (as of April 2019).

(List of collaborations: https://opcfoundation.org/markets-collaboration/)

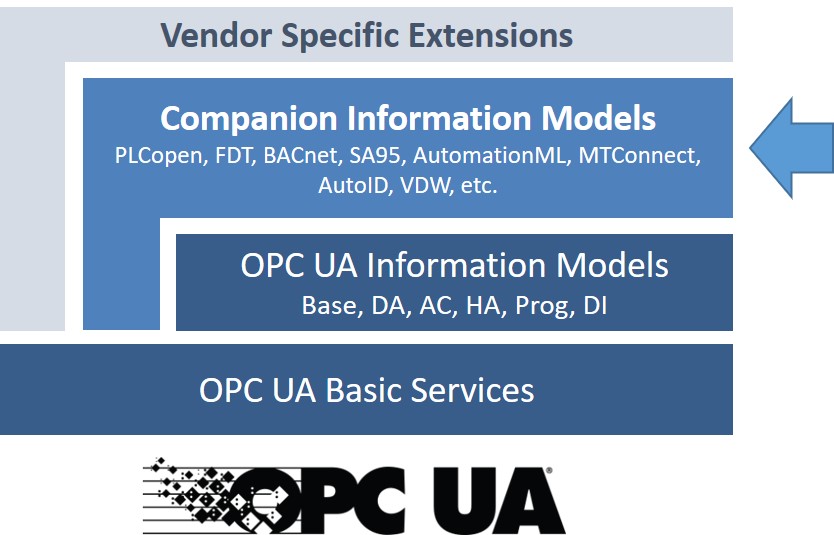

1st World Interoperability Conference, which was intended to show collaboration with OPC UA, was held in parallel to Hannover Messe 2019 in April 2019, and 35 collaboration partners participated.

More than 300 attendees learned about the quality and quantity of collaborations that the OPC Foundation has promoted.

The scope of collaboration is expanding from the factory automation domain to the building automation, energy, oil and gas, and transportation industries and IoT and security domains.

Joint working groups, which members of the OPC Foundation*1 can join, take the initiative to create companion specifications.

*1. Corporate Members and End-User Members, excluding Logo Members.

Collaboration examples

This section shows some examples of collaboration through which companion specifications has been created.

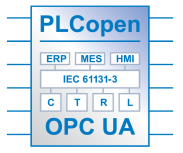

1) PLCopen

This is one of the first collaborations. The OPC Foundation proposed collaboration to the PLCopen in 2006, and they established a joint working group in 2008.

The PLC international standard IEC 61131-3 promoted by the PLCopen was aligned with IEC 62541 (OPC UA) promoted by the OPC Foundation to develop a companion specification. This companion specification enables vendor and platform-independent transfer of control and field data in the PLC to the higher-level system such as Manufacturing Execution Systems (MES) and Supervisory Control and Data Acquisition (SCADA) systems. It was released as version 1.0 in 2010*2.

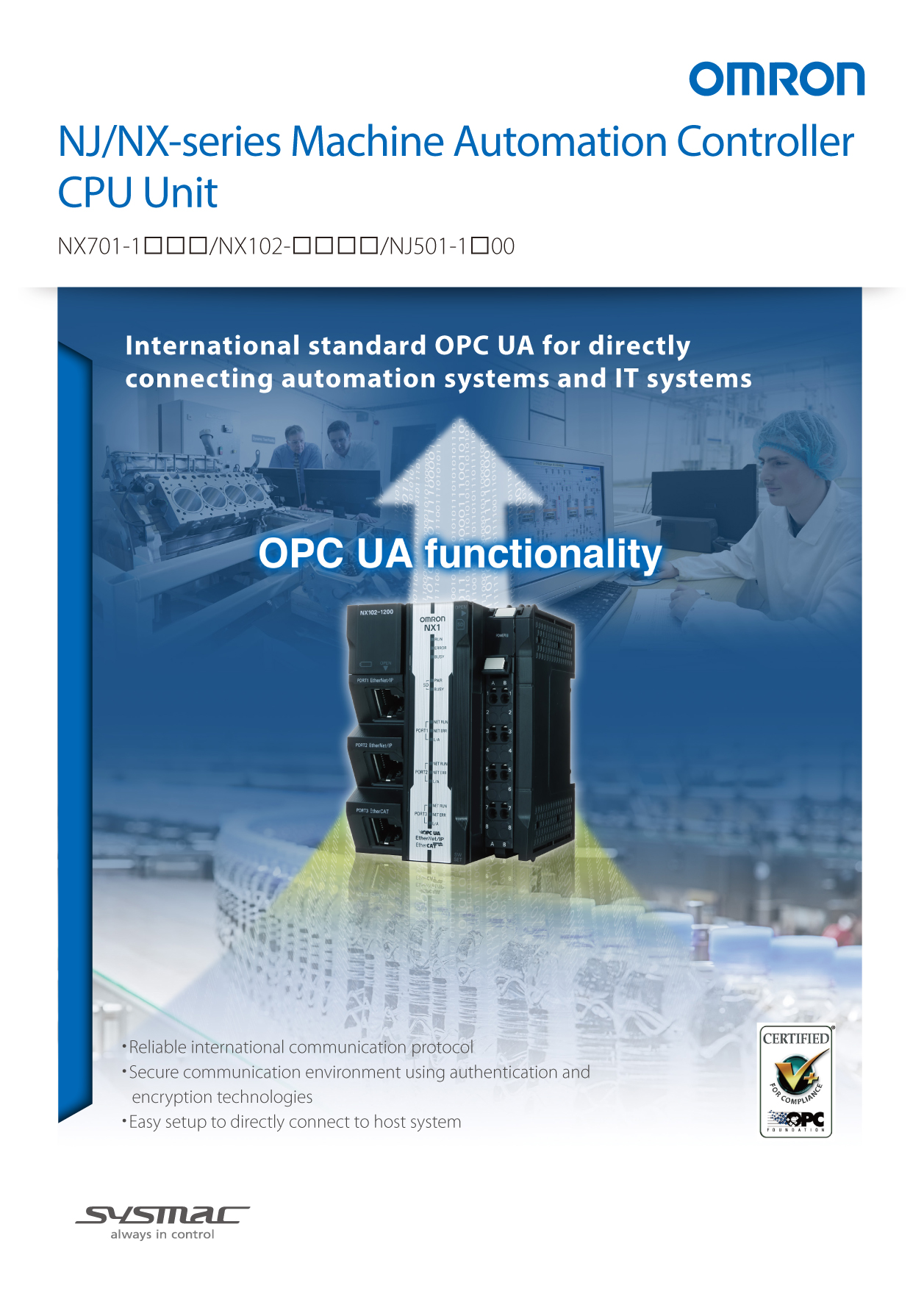

OPC UA integrated into Omron’s NX701-1□□□/NX102-□□□□/NJ501-1□00 complies with this companion specification “OPC UA Information Model for IEC 61131-3”.

They continue to cooperate to promote companion specifications through version upgrades of companion specifications and joint exhibition at events.

2) FDT

FDT is a software interface technology that provides the integrated display method and usability to configure field devices, independent of device manufacturers, models, and communication protocols*3.

Since 2014, FDT Group and the OPC Foundation have worked together to develop companion specifications to apply OPC UA information models to the FDT technology. The FDT/OPC UA specification was released in November 2016, and the demonstration was exhibited at Hannover Messe in 2017.

This companion specification is expected to handle settings and parameters, which are dependent on fieldbus protocols and automation devices, from OPC UA-enabled host systems and applications.

3) OMAC

OMAC (The Organization for Machine Automation and Control)*4 established the Packaging Working Group to reduce installation costs for packaging lines of food and household goods and make packaging operations more effective. They developed a guideline for packaging machines that defines mode and state of devices and interface with host devices. It was released as PackML (ISA-TR88.00.02).

While PackML defines the data structure such as host interfaces, it does not specify a communication protocol. In 2016 OMAC and the OPC Foundation agreed to start examination of the adoption of OPC UA as the PackML standard communication protocol. The data structure and information model defined by PackML were highly compatible with OPC UA, and OPC UA was independent of vendors and platforms, which helped OMAC decide on OPC UA. The joint working group is now developing a companion specification and will be released soon.

Since IEC 61131-3 is the programming standard recommended by OMAC in its guidelines, it was announced that OMAC, PLCopen, and the OPC Foundation would work together for standardization.

*2. PLCopen OPC UA Information Model for IEC 61131-3 specification

https://www.plcopen.org/downloads/plcopen-opc-ua-information-model-iec-61131-3-version-100

*3. FDT Group website

https://www.fdtgroup.org/

*4. OMAC website

https://omac.org/

(To be continued)

- 1. Outline of OPC UA "The Industrial Interoperability Standard"

- 2. Features of OPC UA “Connected, Communicated, Secured”

- 3. Activities of OPC UA (1) Collaboration (this article)

- 4. Working of OPC UA (2) Compliance

- 5. OPC UA Products and Case Studies

- 6. Update on OPC UA

- 7. The proliferation and evolution of OPC UA

- 8. Case Study (Winder with OPC UA)

- 9. A New Initiative for OPC UA

[Reference]

The OPC Foundation website https://opcfoundation.org/

The OPC Foundation website https://opcfoundation.org/

Download our product catalog

for more information!

for more information!

Machine Automation Controller

NJ/NX-series CPU Unit

NX701-1□□□/NX102-□□□□/NJ501-1□00

Photographs are for illustration purposes only and do not represent actual applications.

The system configurations in this page are for reference purposes only.

Sysmac is a trademark or registered trademark of OMRON Corporation in Japan and other countries for OMRON factory automation products.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

Safety over EtherCAT®is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

EtherNet/IP™, CIP Safety™, CompoNet™, and DeviceNet™ are trademarks of ODVA.

OPC and OPC UA are trademarks of the OPC Foundation.

Other company names and product names in this page are the trademarks or registered trademarks of their respective companies.

Microsoft product screen shot(s) reprinted with permission from Microsoft Corporation.

The product photographs and figures that are used in this page may vary somewhat from the actual products.

The system configurations in this page are for reference purposes only.

Sysmac is a trademark or registered trademark of OMRON Corporation in Japan and other countries for OMRON factory automation products.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

Safety over EtherCAT®is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

EtherNet/IP™, CIP Safety™, CompoNet™, and DeviceNet™ are trademarks of ODVA.

OPC and OPC UA are trademarks of the OPC Foundation.

Other company names and product names in this page are the trademarks or registered trademarks of their respective companies.

Microsoft product screen shot(s) reprinted with permission from Microsoft Corporation.

The product photographs and figures that are used in this page may vary somewhat from the actual products.