7. The proliferation and evolution of OPC UA

Selected as a recommended standard for Industry 4.0, OPC UA is gaining even more recognition as the global interoperability standard to serve as the underpinning for manufacturing in the digital age and for DX (digital transformation) in manufacturing. Industrial IoT solutions designed for smart manufacturing are increasingly advertised to "support OPC UA" and therefore more easily connectable or secure.

Omron's "What is OPC UA?" article series has detailed the features of OPC UA, use cases, and trends surrounding the protocol. This article explores how OPC UA has spread and evolved since the publication of the last article of the series, and provides an update on our latest efforts and use cases.

The proliferation of OPC UA

Three developments indicate the increasing prevalence of OPC UA.

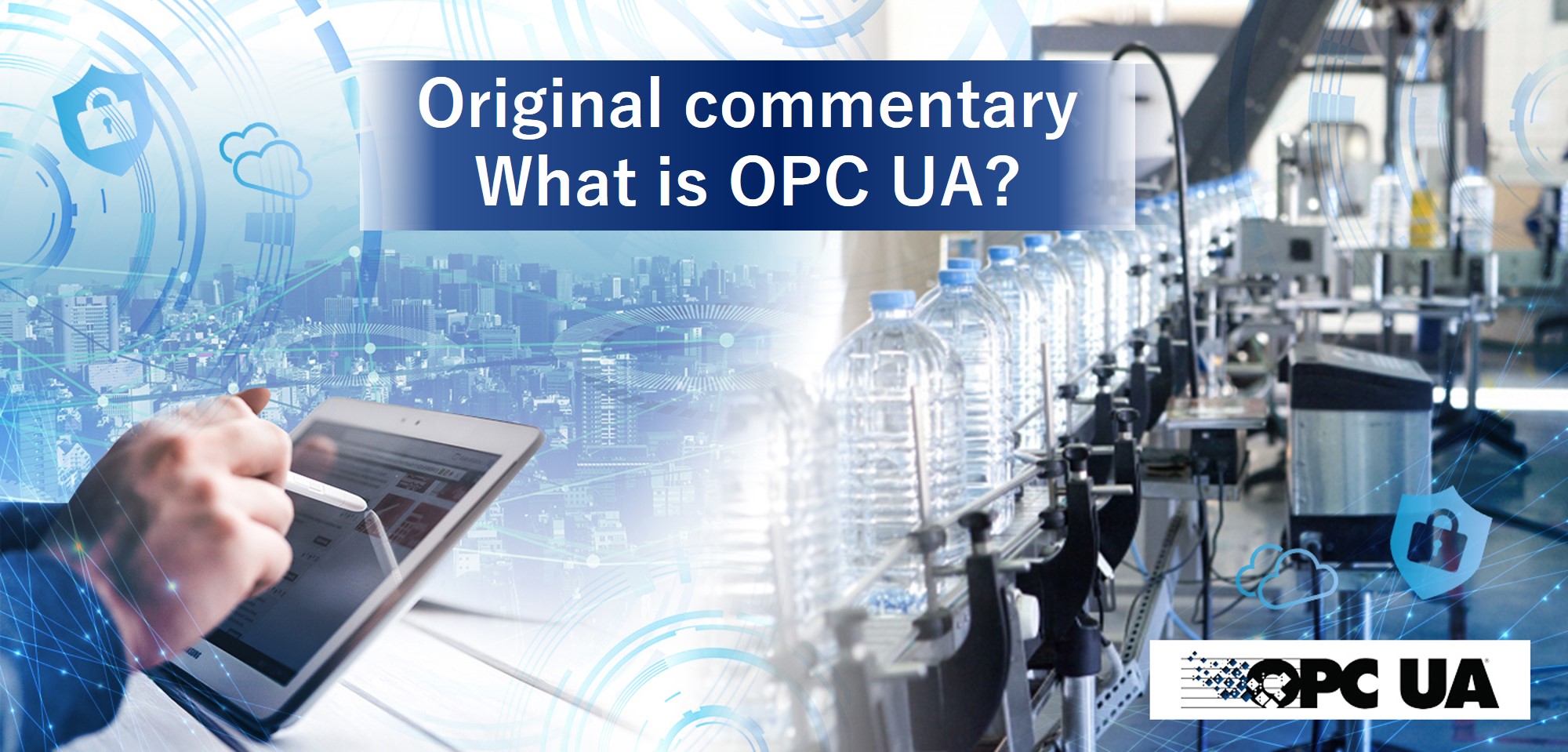

The first of these developments is the continuing rise in membership of the OPC Foundation, which develops and promotes use of the protocol. Membership has grown steadily in the past few years; in 2020, the foundation welcomed its 800th member company.

(Source: OPC Foundation Japan)

The second development is that more of the recent additions to the foundation fall into two previously rare categories: IT companies and end-user companies.

Newer members in the former category include Google Cloud and Amazon Web Services, Inc. (AWS), which means that, because Microsoft has been with the OPC Foundation since its founding, the three largest cloud service providers in the world are now part of the organization. The Japanese telecommunication company NTT Communications has also joined the foundation; as have two major end-user companies: Volkswagen AG, a global car manufacturer, and L'Oreal Operations, the world's largest cosmetics company.

End-user companies own manufacturing sites and therefore drive implementation; while IT companies support implementation by providing technologies that fuel systems for DX in manufacturing. With the participation of companies from both categories, OPC UA use can be expected to grow even more rapidly.

The third and final development is that some countries, such as Singapore and China, are adopting OPC UA as national standards. Singapore has adopted OPC UA as SS IEC62541:2019, while China has adopted it as GB/T 33863. In China, OPC UA is deemed a critical protocol in realizing their industrial initiative, Made in China 2025. OPC UA is expected to spread particularly rapidly in these countries and regions.

As these examples demonstrate, OPC UA is becoming increasingly pervasive across industries, fields, companies, and regions; so much so that some are calling it "The United Nations of automation."

The evolving specifications of OPC UA

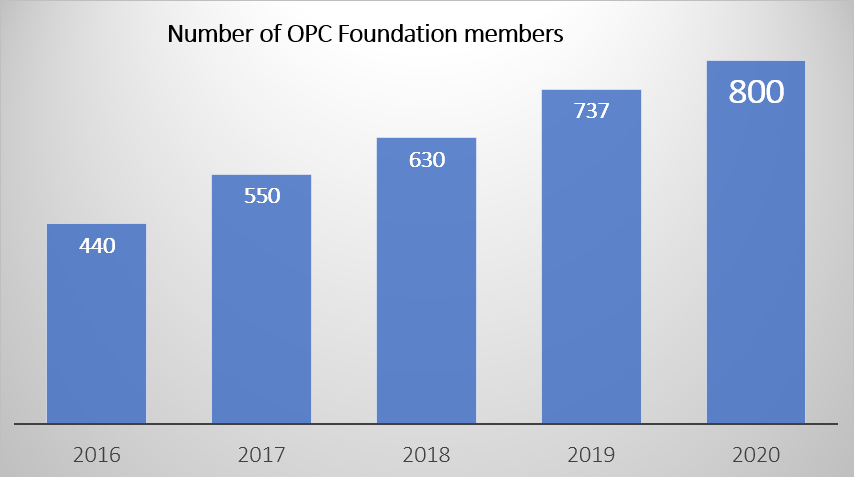

OPC UA was developed to create a world where everything in plants and industries is "connected, communicated, and secured." It has so far mainly served to provide value to vertical interconnections (host/client interconnections ) by acting as a conduit between FA and IT. Going forward, its goal is to broaden its range of provided values to include horizontal interconnections on the production floor. Efforts to meet this goal are led by the Field Level Communication (FLC) initiative, as outlined in our article "6. Update on OPC UA."

As a member of the FLC Steering Committee, Omron is currently working to develop FLC specifications, which are to be released in two steps, namely Version 1 and Version 2.

- ・Version 1: Controller-to-Controller (C2C) (framed in red in below figure)

- ・Version 2: Controller-to-Device (C2D), Device-to-Device (D2D) (framed in green in below figure)

(Source: OPC Foundation Japan)

FLC specifications are still under development and therefore yet to be made public, but a technical paper that provides an overview of FLC has been released and is available for download on the OPC Foundation website. The 40-page document outlines the technologies that comprise FLC and the system configurations that it aims to address, to give readers an idea of the goals of the initiative.

* FLC Initiative Technical Paper: https://opcfoundation.org/flc/

Omron's efforts surrounding OPC UA

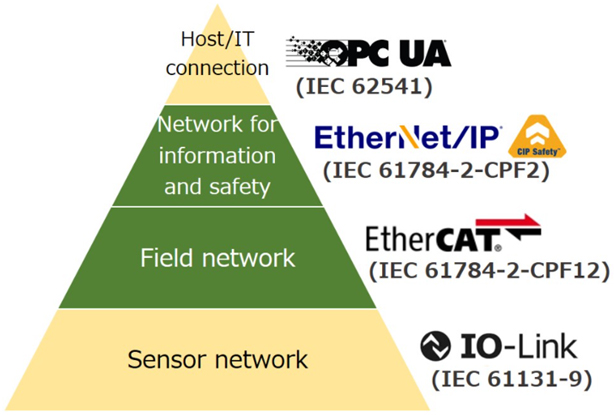

The increasing prevalence of OPC UA has made it a critical protocol for Omron as well. At Omron, we have actively adopted global open industrial network / connection protocols, and offer products that provide total compliance with international standards (IEC)-including sensors, control, data, and host connection-and support open protocols that are becoming more and more pervasive, with OPC UA support for host connections, EtherNet/IP for data/security systems, EtherCAT for field networks, and IO-Link for sensor-level connections.

We expect that OPC UA will only grow in relevance, in harvesting data from controllers, equipment, and field devices such as sensors and robots, and in connecting with host IT systems to analyze and apply this data.

・ Expanding our portfolio of OPC UA products

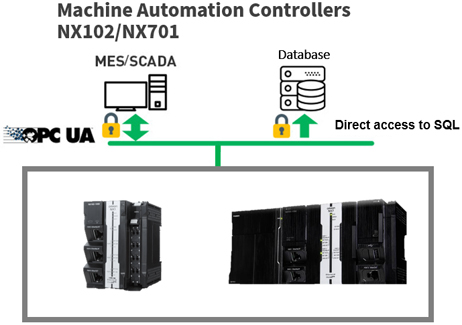

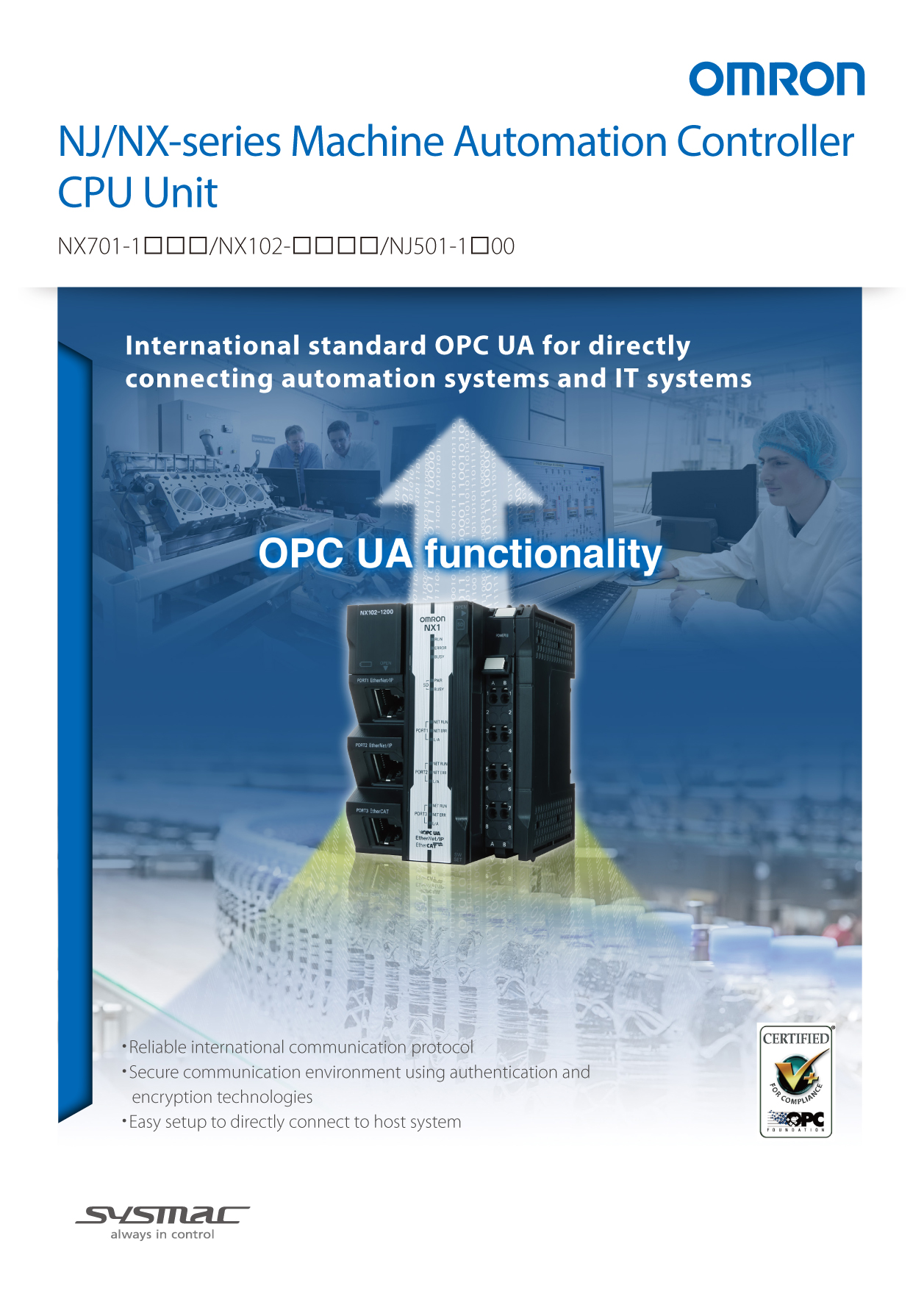

Omron began providing its OPC UA Server in 2018, which has since become a standard feature of our NX102 and NJ501 Machine Automation Controllers. In January 2021, the feature also became standard for the NX701 Series, our most advanced model.

The NX701 Machine Automation Controller's minimum control cycle time of 125 μs and up to 256-axes motion control make it an optimal fit for equipment and processes that require high speed, high accuracy, and large-scale control. Examples of such equipment are high-speed filling machines and packaging machines for drinks and pharmaceuticals; example processes include winding and laminating in the manufacturing of automotive lithium ion batteries. In addition to high-speed/high-accuracy control, such equipment and processes also require MES and production system connectivity, and their data must be stored to quality traceability systems. The NX701 Series can simultaneously and directly connect to two host systems: an OPC UA server and a database.

This two-host connection feature is also provided on our compact NX model, the NX102 Series.

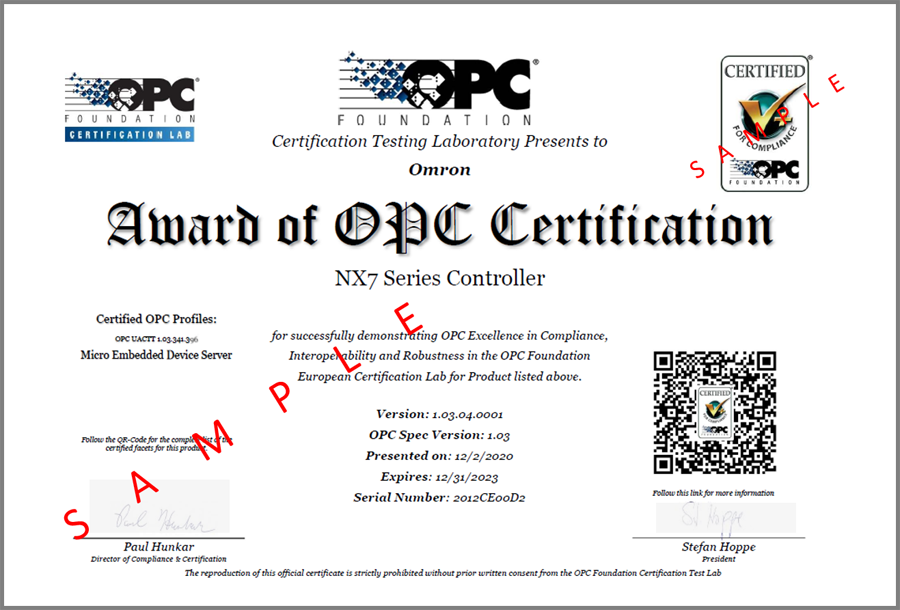

・ Renewal of OPC UA certification

OPC UA was developed to be "the Industrial Interoperability Standard." To make this a reality, it is crucial that systems are built using dependable products that can be reliably connected. At the OPC Foundation, such products are said to be "compliant;" the foundation accordingly offers several services to ensure product compliance, as outlined in "4. Activities of OPC UA (2) Compliance." The service that the foundation is particularly focused on is its "certification tests."

These tests, for which the foundation runs dedicated test labs, ensure that certified products clear a certain threshold of reliability. A product that successfully passes the tests is awarded a certificate and certification logo issued by the OPC Foundation.

The certificate is valid for 3 years.

Omron's NX701-1□□□ Machine Automation Controllers, standardly equipped with OPC UA Server, are OPC UA certified; the NX102-□□□□/NJ501-1□00 Series had their certifications renewed in 2021.

The OPC Foundation recommends the use of OPC UA certified products, a list of which is freely available on their website, allowing users to select products that are highly reliable.

Certified products page: NX1 Machine Automation Controllers

https://opcfoundation.org/products/view/sysmac-nx1-machine-automation-controller

Certified products page: NJ Machine Automation Controllers

https://opcfoundation.org/products/view/sysmac-nj-series-machine-automation-controller

Certified products page: NX7 Machine Automation Controllers

https://opcfoundation.org/products/view/omron-nx7-machine-automation-controller

・ More OPC UA use cases

More customers are now adopting our OPC UA enabled controllers, drawn in particular by their usability and compliance with international standards. In "5. OPC UA Products and Case Studies," we outlined the following four use cases.

- ・Replacing OPC DA with OPC UA

- ・Building a common global information platform for plants

- ・Retrofitting an existing system with operation monitoring features

- ・Ensuring security, preventing manufacturing data falsification (ensuring data integrity)

Below are four more use cases that have emerged since the release of our previous article.

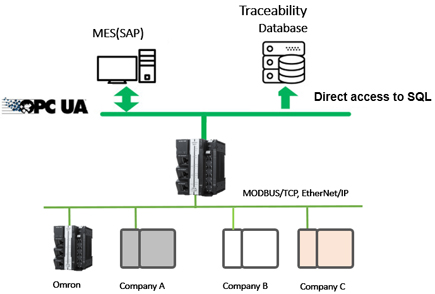

Standardizing MES and traceability database connections

・Retrofitting to existing lines

This customer's production line uses devices and equipment from several different manufacturers, which were connected to host systems in several different ways. NX1 was retrofitted to this production line to standardize the methods for these connections: devices and equipment were connected to the MES (SAP) using OPC UA, while they were directly connected to the quality traceability database. The customer has adopted this framework as their global standard interface and is in the process of introducing it into their other plants as well.

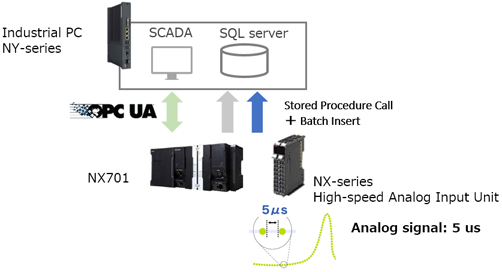

・Implementation to new equipment

A single NX7 Controller unit carries out the following during the final testing process for automotive parts: the collection and analysis of high-speed (several dozen kHz) analog signals necessary for assessment, storage of all test results to the traceability database, displaying the test results and condition of each part on SCADA, and transport control. The collection and analysis of the analog signals and the storage of data to the database are conducted via direct connection, while connection with the SCADA system uses OPC UA.

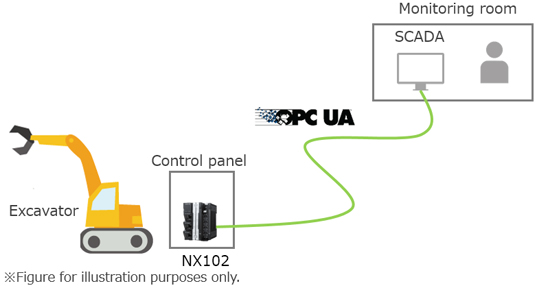

Using OPC UA as a regular equipment interface

・Remote monitoring of excavators

Excavators used in mines are connected to a SCADA system in the monitoring room via OPC UA so they can be monitored remotely. The customer was impressed by how easily the connections could be made without much expertise.

・Connecting data processing IPC with PLC

The equipment in this use case uses an industrial PC (IPC) for image processing and the NX1 Controller for transport control, connected via OPC UA. The OPC UA transmission rate (transmission time less than 100 ms) is seemingly sufficient for this customer's purposes.

At Omron, we will continue to work toward the further proliferation of OPC UA, the industrial interconnection standard.

(The contents of this article are based on information as of February 2021)

- 1. Outline of OPC UA "The Industrial Interoperability Standard"

- 2. Features of OPC UA “Connected, Communicated, Secured”

- 3. Activities of OPC UA (1) Collaboration

- 4. Activities of OPC UA (2) Compliance

- 5. OPC UA Products and Case Studies

- 6. Update on OPC UA

- 7. The proliferation and evolution of OPC UA

- 8. Case Study (Winder with OPC UA)

- 9. A New Initiative for OPC UA

[Reference]

The OPC Foundation website https://opcfoundation.org/

The OPC Foundation website https://opcfoundation.org/

Download our product catalog

for more information!

for more information!

Machine Automation Controller

NJ/NX-series CPU Unit

NX701-1□□□/NX102-□□□□/NJ501-1□00

Photographs are for illustration purposes only and do not represent actual applications.

The system configurations in this page are for reference purposes only.

Sysmac is a trademark or registered trademark of OMRON Corporation in Japan and other countries for OMRON factory automation products.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

Safety over EtherCAT®is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

EtherNet/IP™, CIP Safety™, CompoNet™, and DeviceNet™ are trademarks of ODVA.

OPC and OPC UA are trademarks of the OPC Foundation.

Other company names and product names in this page are the trademarks or registered trademarks of their respective companies.

Microsoft product screen shot(s) reprinted with permission from Microsoft Corporation.

The product photographs and figures that are used in this page may vary somewhat from the actual products.

The system configurations in this page are for reference purposes only.

Sysmac is a trademark or registered trademark of OMRON Corporation in Japan and other countries for OMRON factory automation products.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

Safety over EtherCAT®is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

EtherNet/IP™, CIP Safety™, CompoNet™, and DeviceNet™ are trademarks of ODVA.

OPC and OPC UA are trademarks of the OPC Foundation.

Other company names and product names in this page are the trademarks or registered trademarks of their respective companies.

Microsoft product screen shot(s) reprinted with permission from Microsoft Corporation.

The product photographs and figures that are used in this page may vary somewhat from the actual products.