6. Update on OPC UA

OPC UA is aiming for a world where things are connected, communicated, and secured by expanding the scope to deliver its values in terms of both technology and application.

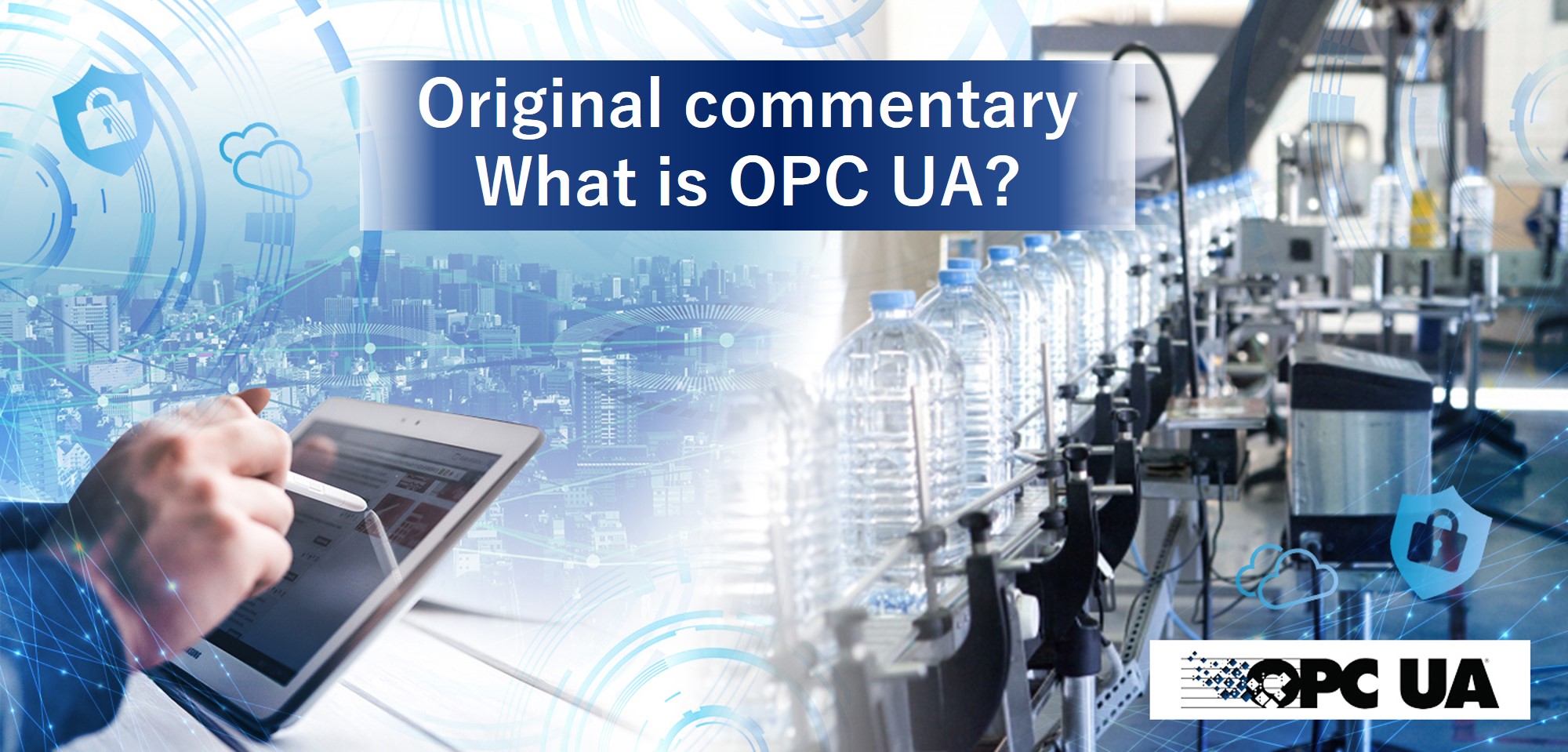

Generation of new value: OPC UA from sensor to cloud

Technologies including OPC UA have provided values through vertical integration with higher-level systems as a bridge between FA and IT. The Field Level Communications (FLC) Initiative aims to provide values through horizontal interoperability on the production floor.

IT/OT communication

Cloud integration

Controller to controller

Controller to field device

Secure remote access

Local OT communication

Wireless integration (5G)

Future ready

Source: OPC Foundation Japan

The OPC Foundation released in November 2018 that they would develop an OPC UA specification for interoperability between controllers and between controllers and robots or field devices. Some working groups were established, and they started to work for standardization. Omron joined the standardization working group as a steering member.

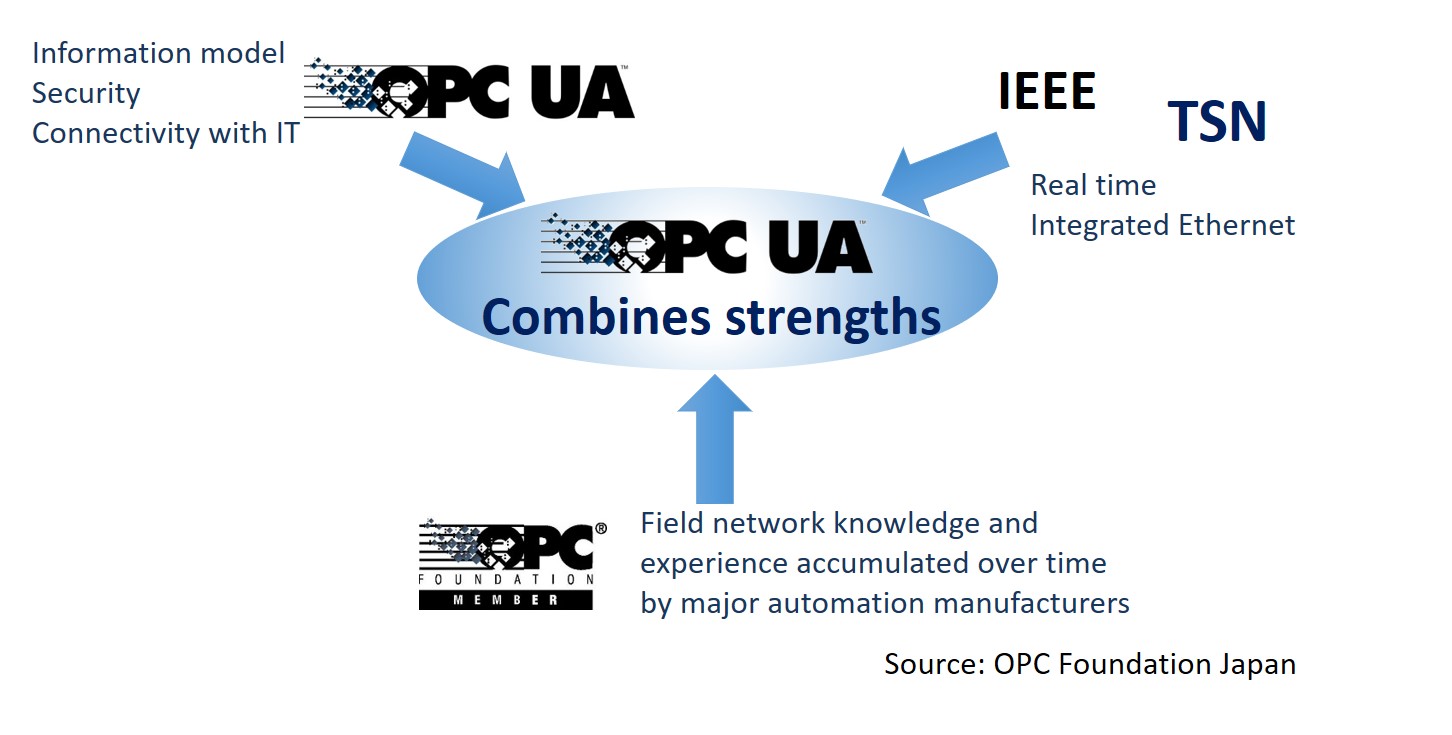

Real time and high speed are essential for industrial interoperability. Technology used to achieve this is TSN (Time Sensitive Networking). TSN is a new Ethernet standard that the IEEE 802.1 working group aims to standardize, enabling time synchronization and packet scheduling. This will ensure real-time operations required for field networks, while maintaining the advantage of standard Ethernet.

The OPC Foundation and its member companies are working together with IEEE to develop an OPC UA standard that integrates the field level.

Further expansion of collaborations

In 3. Activities of OPC UA (1) Collaboration, we looked at active collaborations to enable interoperability. Collaborations are still expanding. This chapter introduces two collaborations:

Expanding at manufacturing: umati (universal machine tool interface)

umati page https://vdw.de/technik-und-normung/umati/

umati is a standard interface for machine tool communication with higher-level IT systems, and its standardization is initiated by German Machine Tool Builders' Association (VDW). It was announced that OPC UA would be adopted as its communication platform.

At EMO Hannover 2019 held in September 2019, the live demonstration by connecting 110 machine tools via the umati interface was exhibited. 70 companies participated in the demonstration.

Expanding outside manufacturing: HKI

Collaboration with HKI https://opcfoundation.org/markets-collaboration/hki/

About 200 manufacturers (as of July 2019) of commercial kitchen equipment are organized at HKI.

HKI developed the information models for 13 types of commercial kitchen equipment (e.g., coffee machine, convection oven, and fryer), aiming for improved interoperability and standardized data exchange. HKI published the release candidate (RC) of the companion specification to members in March 2019.

A six-part series has introduced the outline, features, and specific examples of OPC UA which is becoming increasingly prevalent. We hope that the contents will be of any use to your business and productivity improvement.

(End)

- 1. Outline of OPC UA "The Industrial Interoperability Standard"

- 2. Features of OPC UA “Connected, Communicated, Secured”

- 3. Activities of OPC UA (1) Collaboration

- 4. Activities of OPC UA (2) Compliance

- 5. OPC UA Products and Case Studies

- 6. Update on OPC UA (this article)

- 7. The proliferation and evolution of OPC UA

- 8. Case Study (Winder with OPC UA)

- 9. A New Initiative for OPC UA

[Reference]

The OPC Foundation website https://opcfoundation.org/

The OPC Foundation website https://opcfoundation.org/

Download our product catalog

for more information!

for more information!

Machine Automation Controller

NJ/NX-series CPU Unit

NX701-1□□□/NX102-□□□□/NJ501-1□00

Photographs are for illustration purposes only and do not represent actual applications.

The system configurations in this page are for reference purposes only.

Sysmac is a trademark or registered trademark of OMRON Corporation in Japan and other countries for OMRON factory automation products.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

Safety over EtherCAT®is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

EtherNet/IP™, CIP Safety™, CompoNet™, and DeviceNet™ are trademarks of ODVA.

OPC and OPC UA are trademarks of the OPC Foundation.

Other company names and product names in this page are the trademarks or registered trademarks of their respective companies.

Microsoft product screen shot(s) reprinted with permission from Microsoft Corporation.

The product photographs and figures that are used in this page may vary somewhat from the actual products.

The system configurations in this page are for reference purposes only.

Sysmac is a trademark or registered trademark of OMRON Corporation in Japan and other countries for OMRON factory automation products.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

Safety over EtherCAT®is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

EtherNet/IP™, CIP Safety™, CompoNet™, and DeviceNet™ are trademarks of ODVA.

OPC and OPC UA are trademarks of the OPC Foundation.

Other company names and product names in this page are the trademarks or registered trademarks of their respective companies.

Microsoft product screen shot(s) reprinted with permission from Microsoft Corporation.

The product photographs and figures that are used in this page may vary somewhat from the actual products.