5. OPC UA Products and Case Studies

OPC UA is now used for secure and open production systems that multiple vendors can adopt. This article shows OPC UA products and case studies.

OPC UA server

PLC and controller

Omron and major PLC and controller manufacturers worldwide offer products with the OPC UA server interface.

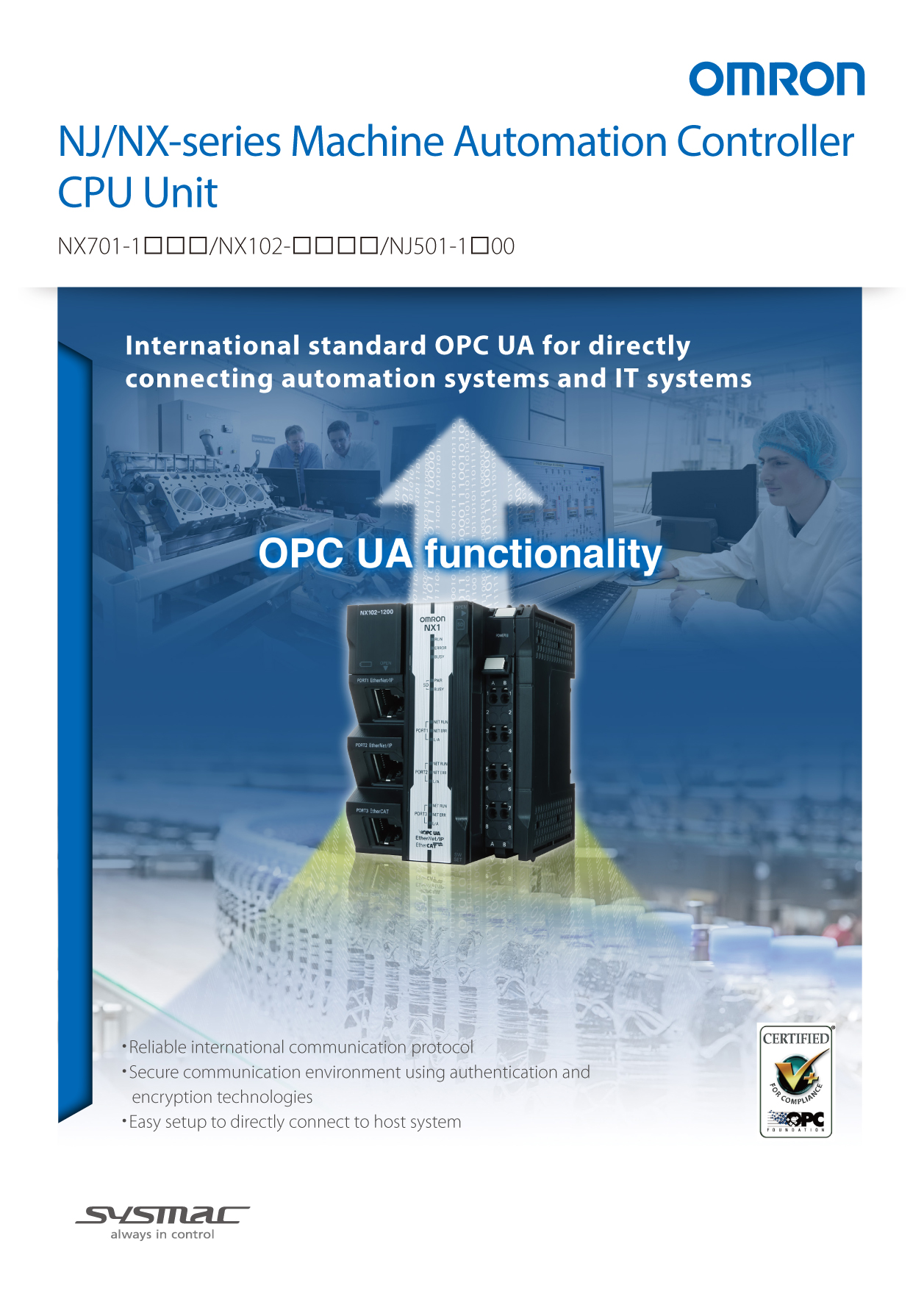

Machine Automation Controller NX701-1□□□/NX102-□□□□/NJ501-1□00

This controller with OPC UA server functionality can access PLCopen information models. This allows the controller to be directly connected to the higher-level IT system (e.g., SCADA) just by selecting controller variables.

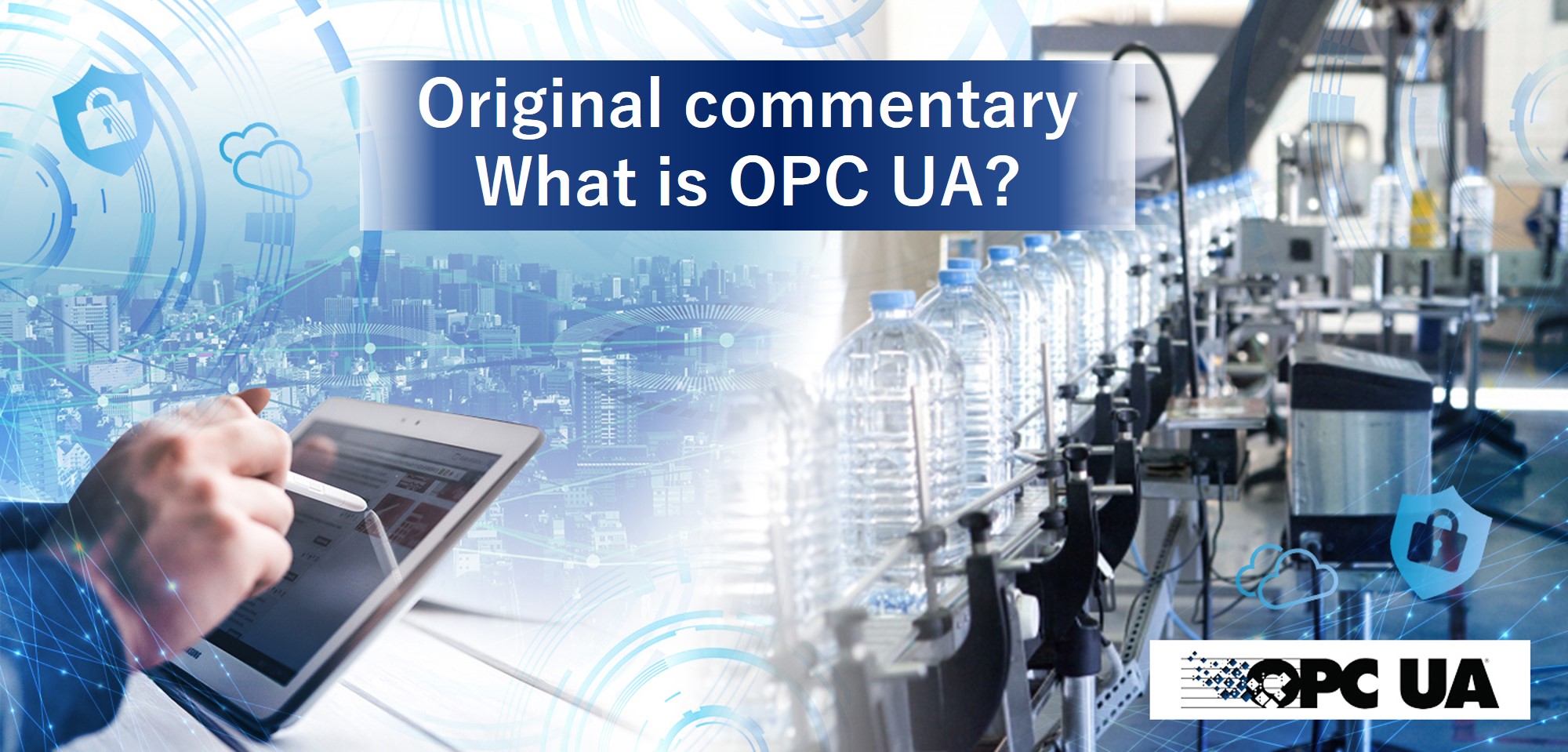

The NX102 Series comes equipped with database connection functionality as well as OPC UA server functionality.

One controller can be connected to both the higher-level system and database: MES or SCADA via OPC UA, and SQL Server or Oracle Database used for traceability via database connection.

The NX102 Controller supports not only OPC UA and database connection but various networks including EtherNet/IP, EtherCAT, MODBUS/TCP, and SLMP. It also offers IO-Link connectivity that makes communication down to the sensor level visible. Combining versatile connectivity with OPC UA brings IT and IoT to manufacturing sites.

DCS

The OPC UA server is also integrated into Distributed Control Systems (DCS) for process control of oil refinery plants and chemical plants. Find products with OPC UA server capabilities on the Certified Products page of the OPC Foundation website.

Certified Products page of the OPC Foundation

Certified products include many DCS products.

OPC UA client

This section shows some examples of software with an embedded OPC UA client that is used together with an OPC UA server such as PLC.

(Note: The software below could be connected in the interoperability workshops (IOP) held by the OPC Foundation, actual systems, or demonstration systems. However, this does not mean that Omron recommends these products or guarantee the connection.)

FANUC MT-LINKi

PC software provided by FANUC Corporation for collecting and visualizing the machine information in the factory.

FANUC MT-LINKi page

Information can be collected from equipment such as machine tools with FANUC CNC, FANUC robot controllers, and PLCs supporting OPC UA communication.

InduSoft Web Studio

This is SCADA development software offered by InduSoft, Inc. in the United States.

InduSoft Web Studio page

The OPC UA client has been embedded for long.

Puerto UA Monitor

Puerto Co., Ltd. in Japan provides Excel add-on OPC UA client.

Data can be read from or written to the OPC UA server like a PLC in the familiar Excel environment.

See the demonstration video of Omron’s NX102 Controller connected with Puerto UA Monitor.

Demonstration video of NX102 and Puerto UA Monitor (Japanese)

OSIsoft PI System

This product offered by OSIsoft in the United States (https://www.osisoft.jp/) is an IoT platform that can collect, accumulate, and manage huge amounts of data in real time. PI Connector for OPC UA enables real-time data collection from the OPC UA server such as PLC.

See the demonstration video of Omron’s NX102 Controller connected with PI System.

Demonstration video of NX102 and PI System (Japanese)

Node-RED

Node-RED is an open source software (OSS) visual programming tool developed by the OpenJS Foundation project, which allows you to program on a web browser, create IoT applications, and display data.

See the demonstration video of Omron’s NX102 Controller connected with Node-RED.

Demonstration video of NX102 and Node-RED with OPC UA (English)

OPC UA development kit

The use of SDK or other development kits makes development of the software and systems for OPC UA more efficient.

Provided by the OPC Foundation

The OPC Foundation provides open-source OPC UA stacks and sample applications on GitHub.

GitHub page of the OPC Foundation

Everyone can use them. However, attention should be paid to commercial use because they are licensed under GPL v2. The stacks available to The OPC Foundation Corporate Members are under RCL license, allowing commercial use without the need to disclose source code for applications using the stacks.

Certified OPC UA SDK offered by OPC Foundation Corporate Member companies

Various OPC Foundation Corporate Member companies offer certified OPC UA SDK.

Certified Products page of the OPC Foundation

Case studies

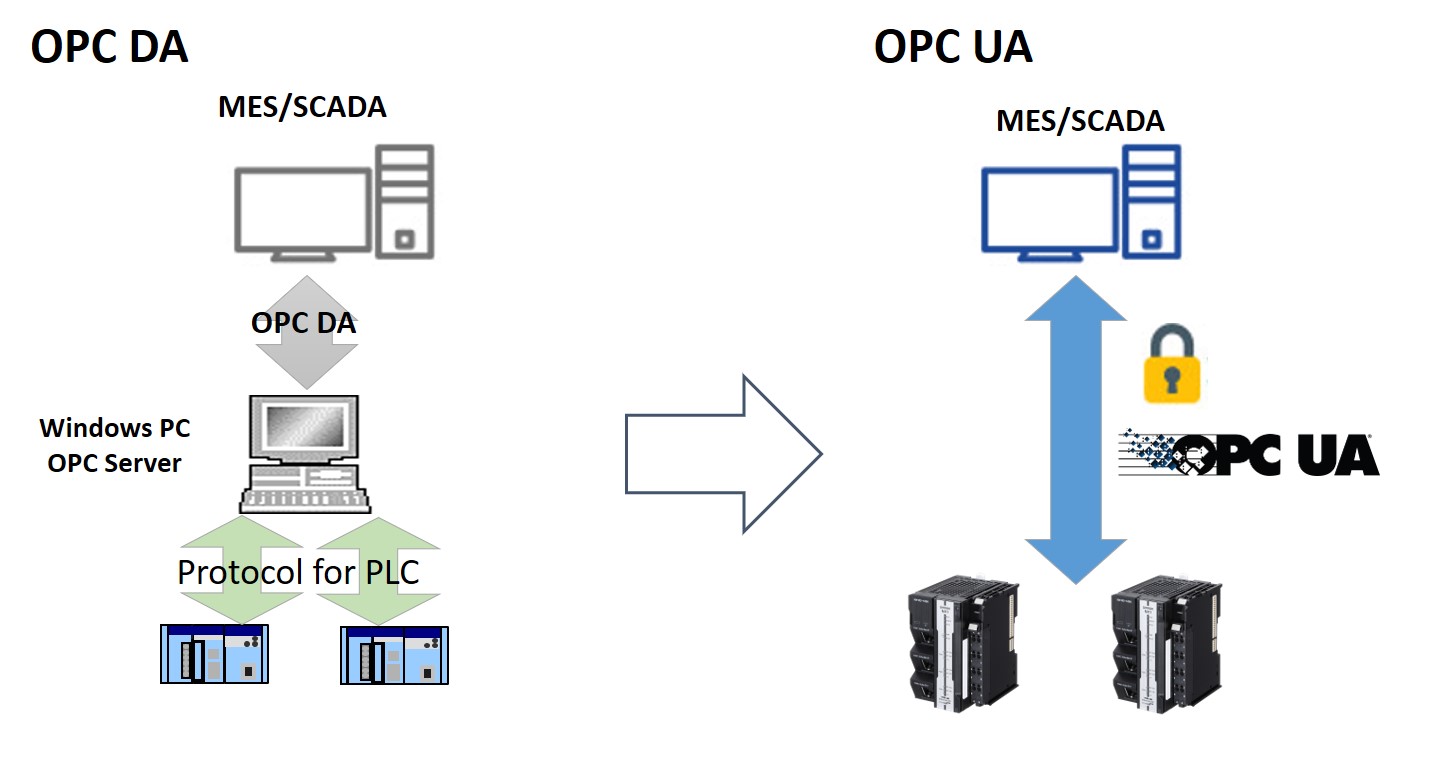

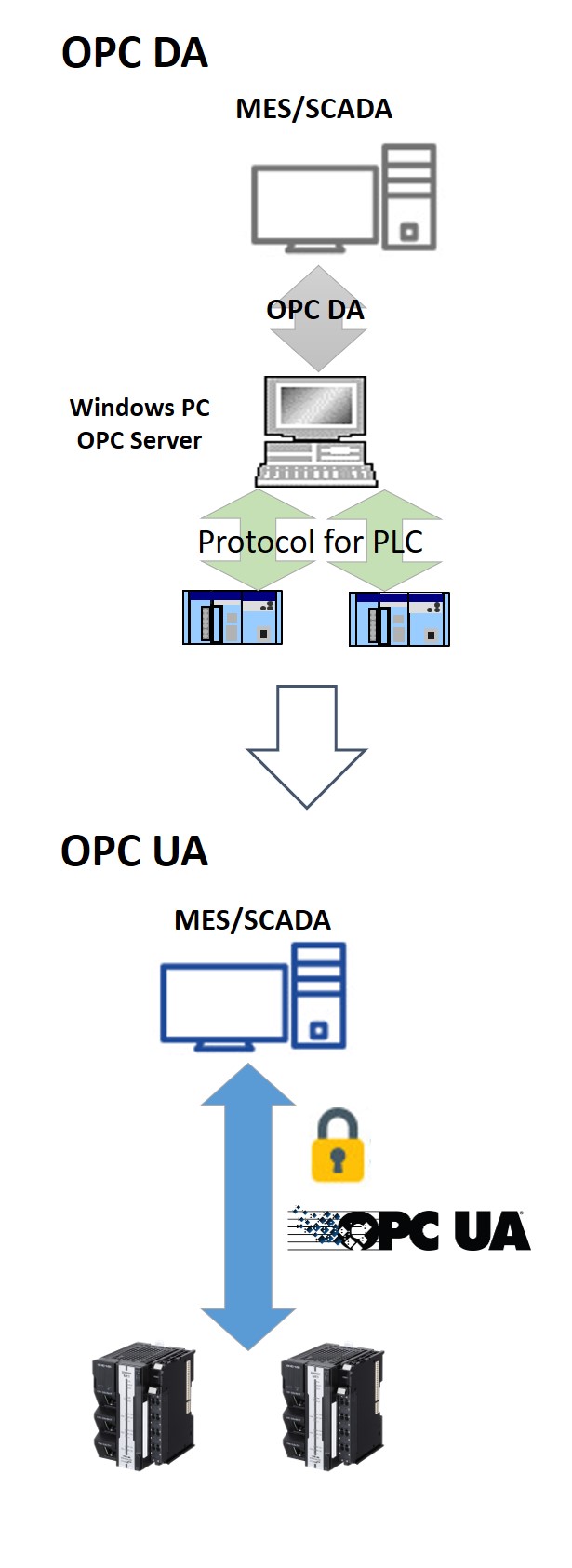

Update supervisory control system from OPC DA to OPC UA

The first-generation OPC technology OPC DA has been used for supervisory control and operation monitoring systems for factories. OPC UA is increasingly adopted for updating the systems. Improved points are:

・ Direct connection with PLC or control devices as well as Windows PC makes the system configuration simple.

・ In addition to simple numerical and memory data, structured data and semantic information can be exchanged.

・ Security is enhanced.

A broad range of OPC UA-capable SCADA, PLC, and controllers boost the adoption of OPC UA.

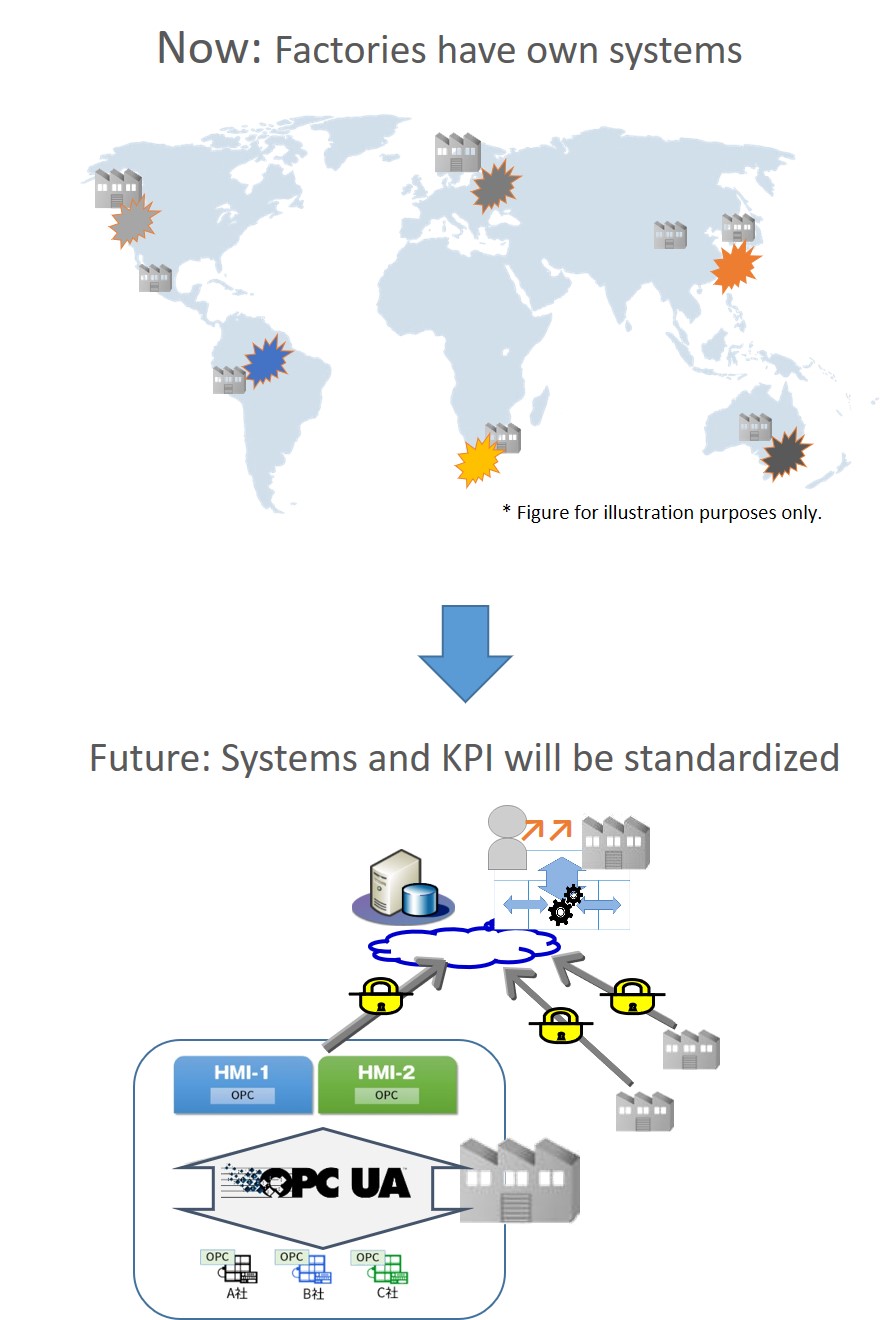

Standardize IT foundations with OPC UA for smart factories around the world

Manufacturing sites around the world have their own IT systems. M&A is one of the reasons. In order to improve productivity by leveraging information across the company, KPI and systems need to be standardized. The adoption of OPC UA as a globally standard, future-proof foundation solves this challenge.

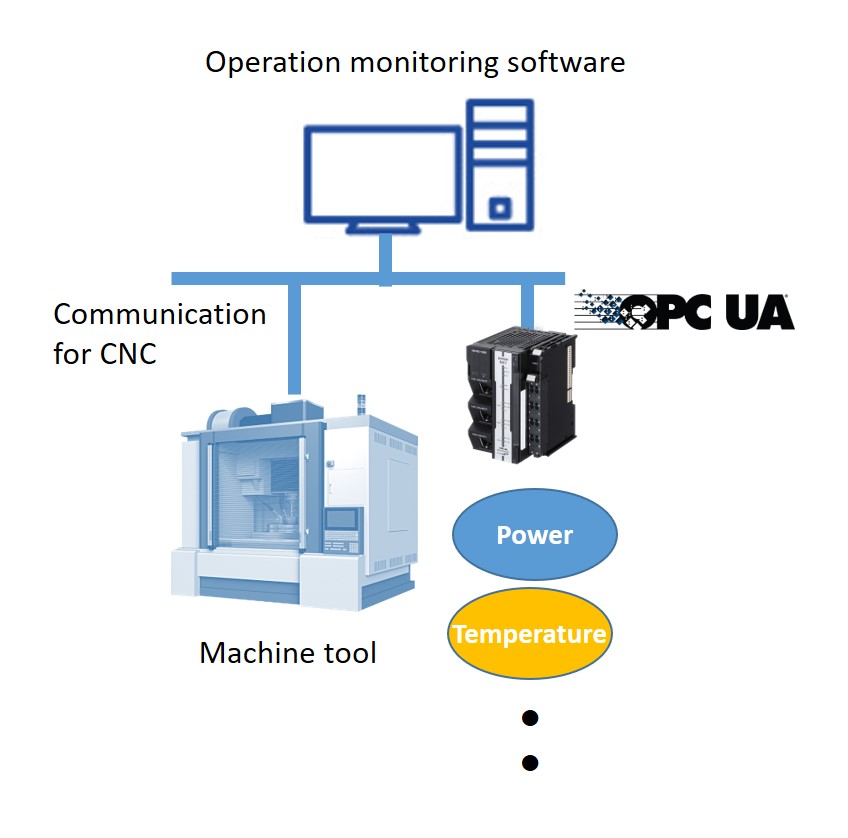

Monitor operation of metalworking lines

OPC UA is used to collect and visualize data, such as operation information of CNC machine tools on metal parts processing lines, information of devices controlled by the PLC, and environmental information like power and temperature. One system can collect and manage both CNC and PLC information.

Security measure

Secured OPC UA can be used for cyber security and protection against manipulation of production data to achieve safe and secure manufacturing.

・ Cyber security measure

Most of actual applications are not disclosed, but Nagoya Institute of Technology in Japan published the details and results of empirical research on cyber security using OPC UA.

・ Protection against manipulation of production data

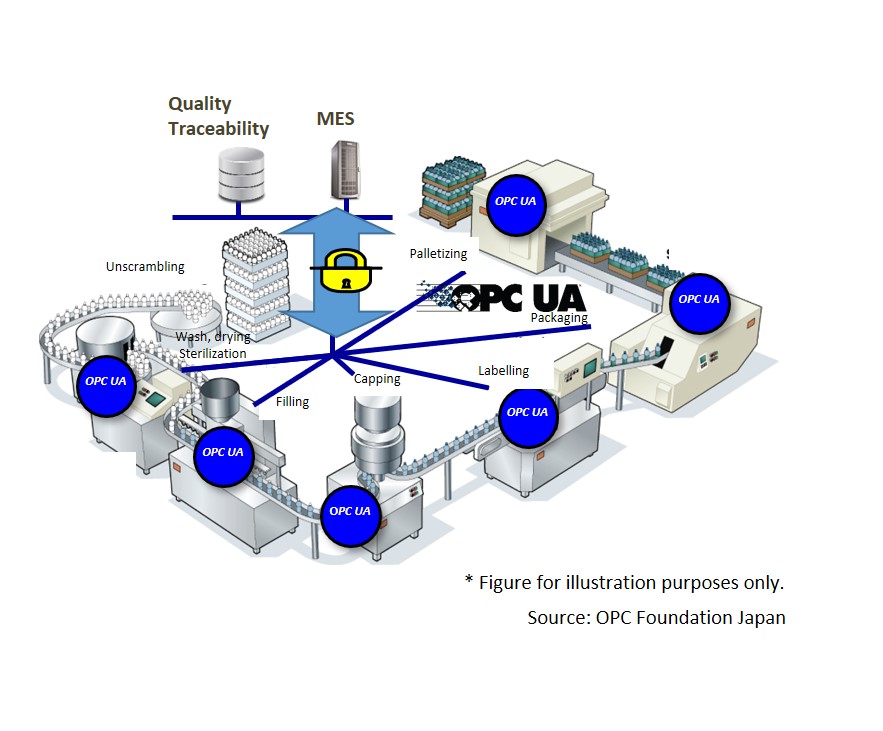

There is an increasing need to ensure the data integrity (DI) of production data collected from production lines and machines in the pharmaceutical industry. Data integrity means assuring the completeness and consistency of data.

OPC UA with digital signatures is sometimes used as a way to facilitate ensuring the data integrity.

(To be continued)

- 1. Outline of OPC UA "The Industrial Interoperability Standard"

- 2. Features of OPC UA “Connected, Communicated, Secured”

- 3. Activities of OPC UA (1) Collaboration

- 4. Activities of OPC UA (2) Compliance

- 5. OPC UA Products and Case Studies (this article)

- 6. Update on OPC UA

- 7. The proliferation and evolution of OPC UA

- 8. Case Study (Winder with OPC UA)

- 9. A New Initiative for OPC UA

[Reference]

The OPC Foundation website https://opcfoundation.org/

The OPC Foundation website https://opcfoundation.org/

Download our product catalog

for more information!

for more information!

Machine Automation Controller

NJ/NX-series CPU Unit

NX701-1□□□/NX102-□□□□/NJ501-1□00

Photographs are for illustration purposes only and do not represent actual applications.

The system configurations in this page are for reference purposes only.

Sysmac is a trademark or registered trademark of OMRON Corporation in Japan and other countries for OMRON factory automation products.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

Safety over EtherCAT®is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

EtherNet/IP™, CIP Safety™, CompoNet™, and DeviceNet™ are trademarks of ODVA.

OPC and OPC UA are trademarks of the OPC Foundation.

Other company names and product names in this page are the trademarks or registered trademarks of their respective companies.

Microsoft product screen shot(s) reprinted with permission from Microsoft Corporation.

The product photographs and figures that are used in this page may vary somewhat from the actual products.

The system configurations in this page are for reference purposes only.

Sysmac is a trademark or registered trademark of OMRON Corporation in Japan and other countries for OMRON factory automation products.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

Safety over EtherCAT®is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

EtherNet/IP™, CIP Safety™, CompoNet™, and DeviceNet™ are trademarks of ODVA.

OPC and OPC UA are trademarks of the OPC Foundation.

Other company names and product names in this page are the trademarks or registered trademarks of their respective companies.

Microsoft product screen shot(s) reprinted with permission from Microsoft Corporation.

The product photographs and figures that are used in this page may vary somewhat from the actual products.