Temperature has wide-ranging impacts on the quality of smaller and multilayered semiconductor products, which are essential to building a highly digitalized society. NX-HTC, with its ability to save space and visualize feature values, helps improving quality and productivity while delivering rigorous temperature control.

NX-HTC

NX-series Advanced Temperature Control Units

Combining Space-Saving Design and Advanced Temperature Controllability

- Features

- Lineup

- Specifications

- Dimensions

- Catalog

last update: April 24, 2023

Adapting to precise temperature control for semiconductor innovation

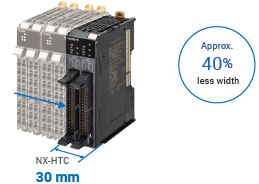

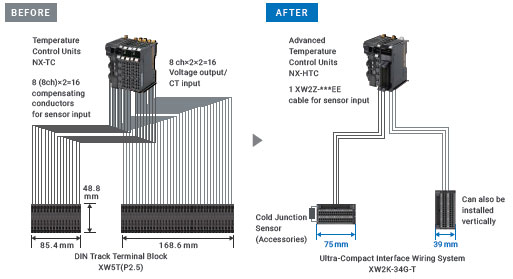

NX-HTC controls multi points while keeps the footprint

【Issues】Cannot maintain footprint because additional equipment is needed to increase in

temperature control subjects

Delivers multipoint control within existing footprint

Save more space by using together with XW2K ultra-compact interface wiring system

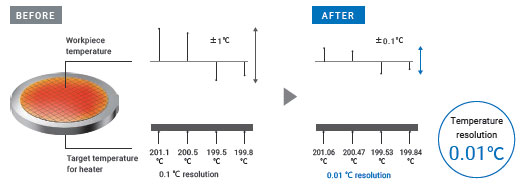

Higher resolution enables adaptation to fine process precision

【Issues】Finer temperature control required for high-precision processing of smaller workpieces

Wide-range, high-resolution temperature control

Supports universal input and works with infrared thermosensor

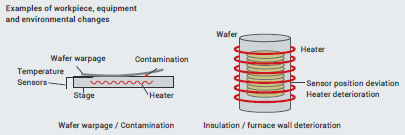

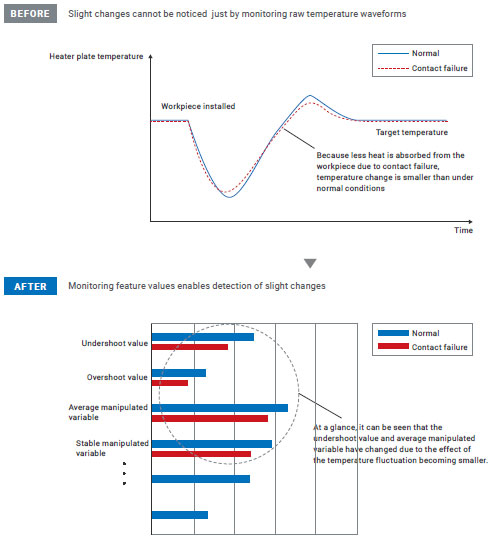

Reduction of production yield by detecting slight temperature profile fluctuations due to changes in conditions such as workpieces, equipment and environment

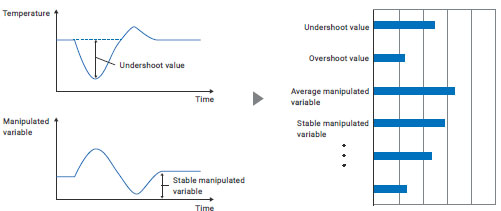

About Feature Visualization function

Monitors trends in feature value data to detect workpiece, equipment and environmental changes

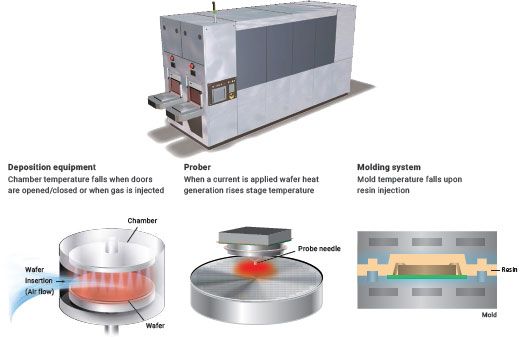

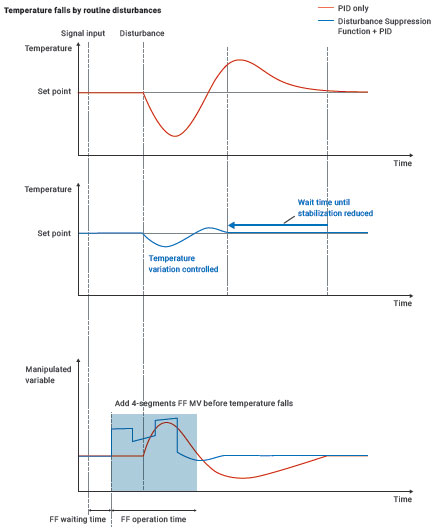

Maximize quality and production capacity by minimizing temperature fluctuations caused by routine disturbances

Automatically suppresses temperature variations caused by routine disturbances

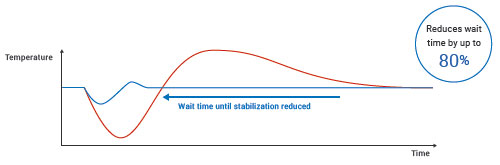

Helps boost production capacity

By suppressing temperature variations, reduces wait time until temperature stabilizes by up to 80%

*Data measured by OMRON

Disruption Suppression Feature minimizes temperature deviations

The Disturbance Suppression Function is a control function that automatically suppresses temperature variations that are expected to be caused by foreseeable disturbances. Trigger signals input to the temperature controller before these disturbances occur turn the function on, which adds to or subtracts from the manipulated variable (MV). Disturbance autotuning automatically adjusts the FF (feedforward) MV, FF operation time, and FF waiting time.

last update: April 24, 2023