Introducing the next generation VHV5 Code Reader designed to meet the diverse needs of multiple industries. With its advanced front-end imaging system, new X-Mode 6.0 decode algorithm, and powerful multi-core processing subsystem, the VHV5 is engineered to handle everything from the highest speed labeling lines, to the most complex direct part mark reading applications right out of the box.

The VHV5 is Ideal for any industry: Food, Beverage & Commodities, Automotive/EV, Logistics Automation, Electronics, White Goods, High-Speed Printing, and Document Handling. The VHV5 Code Reader delivers unparalleled performance and reliability for any code, any application, any operator, or any production line.

VHV5-F

Autofocus Multicode Reader

High-performance barcode reader.

- Features

- Lineup

- Specifications

- Dimensions

- Catalog

last update: July 1, 2025

Introducing the Next Generation in Code Reading

Any Code

X-Mode 6.0 Out of the Box Reading – No Tuning Required

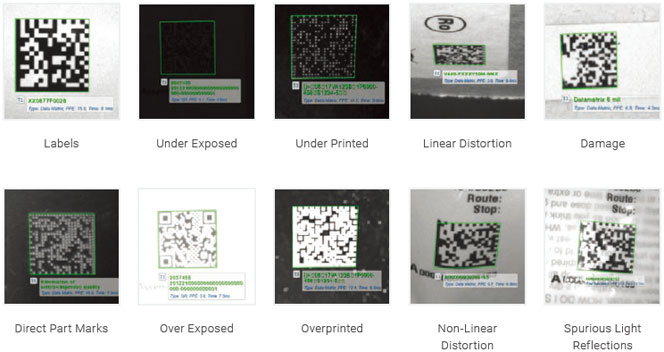

The new X-Mode 6.0 algorithm just reads. All standard 1D and 2D barcode printed labels and direct part marks are effortlessly read by the OMRON X-Mode 6.0 algorithm right out of the box – no special settings, operator intervention or tuning required.

Examples of Standard X-Mode 6.0 Reading Capability

Smart Assist

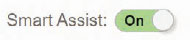

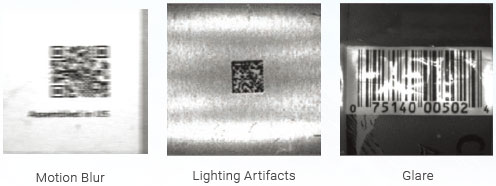

Smart Assist is a powerful new capability introduced in WebLink 4.0. Smart Assist is an Intelligent Processing Mode invoked with a single switch. It boosts the power of X-Mode 6.0 to achieve 99.99%+ read rates on the most damaged, distorted, poorly printed, and poorly imaged codes.

• Automatically applies the correct filters and settings: When enabled, Smart Assist detects the specific code type and problem, and then automatically applies the relevant advanced parameters and image enhancement filters necessary to decode. Specialized user knowledge and the long and exhaustive setup and test cycles become a thing of the past using this new feature.

Examples of Extreme Code Problems Solved by Smart Assist

Optimize

Optimize is an alternative to Smart Assist used when a line is set up to run just a single part type. Optimize delivers the same decoding power as Smart Assist, while at the same time it maximizes decoding speed and minimizes decode time variation from part to part. This allows the production line to be triggered at the fastest possible rate.

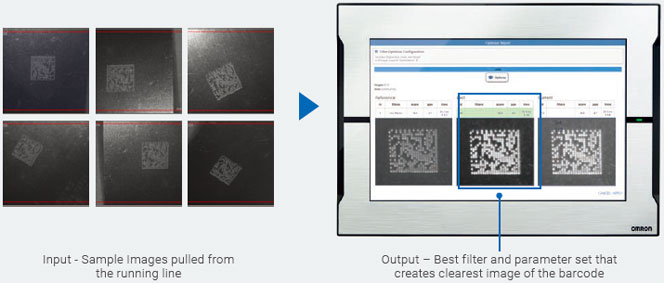

Typical optimize routines are trained during setup on a single part. The “optimize solution” they produce is based solely on just one example of the way the code appears. The VHV5 optimize routine however can be trained on a sample set of up to 7 images pulled from the running line. This larger sample set better represents the true variation in the way codes will appear during production due to normal changes in part position, lighting, marking, code quality and other factors. The VHV5 “optimize solution” calculated from this larger image set is far more robust

Optimization in Action:

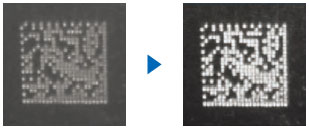

Training

The Optimization training routine pulls the set of test images from the running line and stores them away. It then iterates through all images, systematically changing key parameters and image preprocessing combinations to find the best solution for the entire group. The best solution is the one that separates the foreground and background code cells into tight groupings with a clearly defined threshold between them.

Runtime

During runtime, the effect is that codes are:

• Easier to locate within the image

• Easier to decode

• Read times are very fast

• Read times are very consistent

Optimize Reading Real-World Variations Right out of the Box

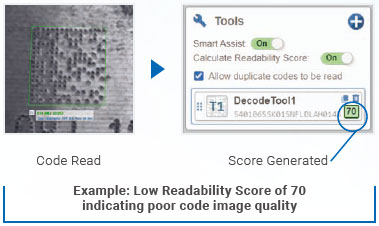

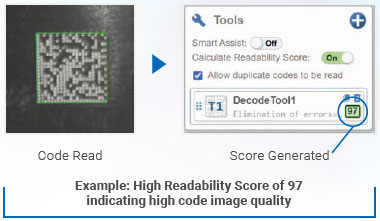

Readability Score (0-99)

The Readability Score directly reflects the quality of the code, and the ease with which the algorithm can locate and decode it. The score is continuously calculated and output during normal operation. The score is very useful during setup to help choose the correct lighting. It is, also very useful during runtime to help identify and correct marking problems before they become a production issue.

How Readability Score Works:

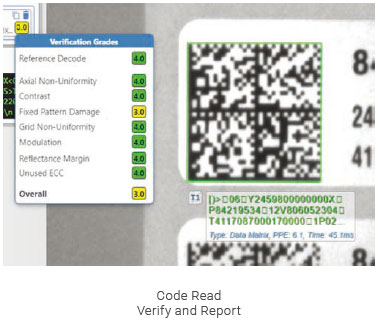

Code Quality Monitoring

Using industry-standard ISO 15416, 15415, and 29158 algorithms, the VHV5 measures code quality in real-time. The VHV5 advanced processor can run in-line verification at rates up to 1200 parts per minute. Built-in lighting is able to ensure accurate results. The camera can also connect to and drive external ISO standard-lighting, if required.

Any Application

VHV5 - Maximum Versatility for Any Industrial Application

• IP69K Packaging: Offers the highest available IP Rating for installation in any industrial environment.

• Flexible Mounting Options: Adapt to various setups with ease.

• Optical Flexibility: Choose from clear window, diffuser, polarizer, and half-polarizer options to enhance image clarity.

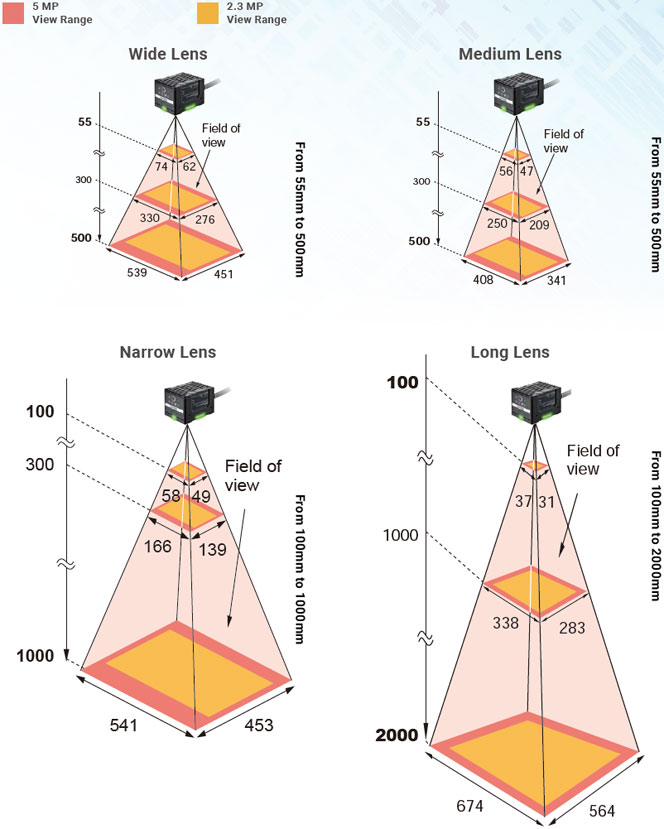

• Wide Autofocus Range: The choice of four different liquid lenses and two sensor resolutions provides maximum flexibility to match the camera to the exact optical and mechanical requirements of the application.

• Ultra High Power Lighting: Red and white lighting perfect for stop-motion, wide area, and long-range imaging.

• Ready-to-Use Algorithms: Automatically reads all barcode types out-of-the-box, including single or multiple codes, and performs well with both low-quality direct part marks and high-contrast labels.

• High-Speed Performance: Multi-core processing and advanced algorithms ensure up to 4000 parts per minute, with the fastest, most consistent reads even for challenging Direct Part Marks.

• Flexible Connectivity and Networking Options: The VHV5 offers a variety of high-speed networking options for integrations into modern assembly lines as well as legacy connectivity options such as serial communications and digital I/O.

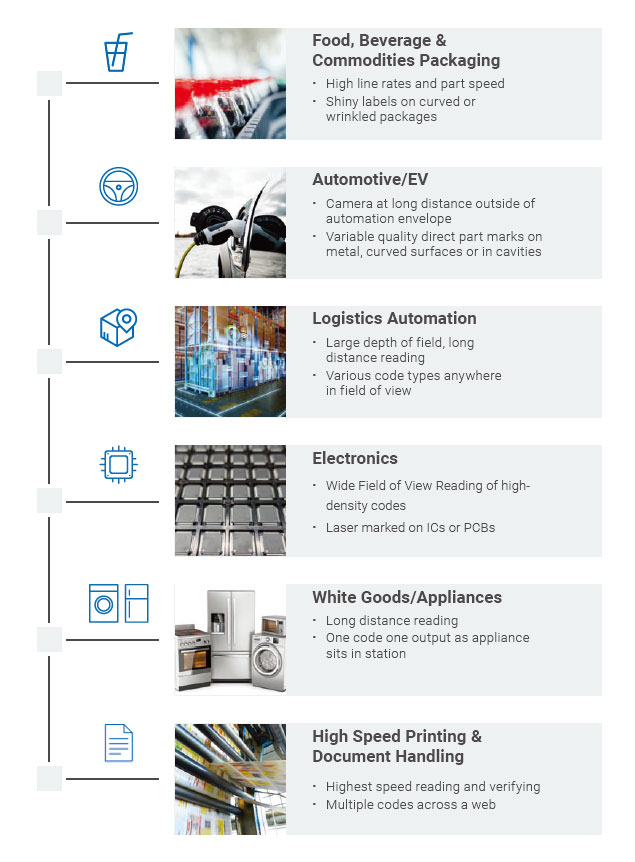

VHV5 Target Application Industries/Markets

The VHV5 has been designed for use across a broad array of industries, each with their own sets of unique requirements and customer pain points. The VHV5 has the built in capabilities to tackle both the simple and the most challenging applications where traceability is a critical requirement

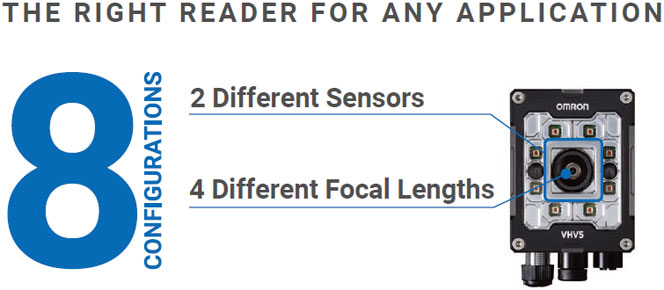

Multiple Configurations

The versatility starts with 8 standard models derived from a combination of two different sensors, and four different focal length, high speed AutoFocus lenses.

The 8 combinations allow the user to pick exactly the right reader model that matches the application requirements.

The 8 combinations allow the user to pick exactly the right camera model that matches the application requirements in terms of field of view, camera standoff, and the required resolution to read the designated code size.

Multiple Configurations

IP Rating

The VHV5 is IP69K rated. This is the highest IP device rating available for protection against dust and water. This means the VHV5 can be installed in virtually any industrial environment no matter how harsh.

Flexible Mounting

The VHV5 offers Multiple options for direct mounting using mounting holes either on the side or back of the unit, or by using 1 of 3 highly flexible mounting options designed specifically for the camera.

Multiple Communication Options

The three connectors on the bottom of the camera allow the user the choice of programming and control through 1000 BaseT (PoE) TCP/IP, EtherNet/IP, PROFINET, or through a combination of the above. This allows the VHV5 to be integrated into the most modern assembly lines, as well as the legacy lines using serial communications or digital IO.

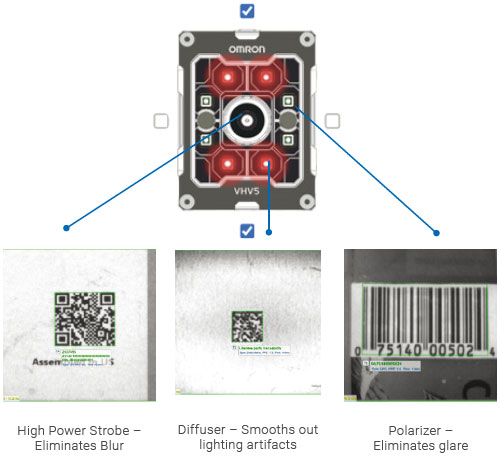

Imaging Front End Lighting and Filtering Options

The VHV5 lighting is 15x brighter than the previous generation camera lighting. This allows the camera to operate from 50 mm to over 2000 mm, evenly illuminating the entire field of view with no motion blur using just the integrated light. Most products in its class require multiple external lights to achieve the same results.

The camera’s ultra-bright strobe lighting can be accessorized with a Diffuser, Polarizer, or Half Polarizer which gives the user very powerful options to create clean, high contrast images of the barcode, further enhancing the VHV5 versatility to image parts of all types.

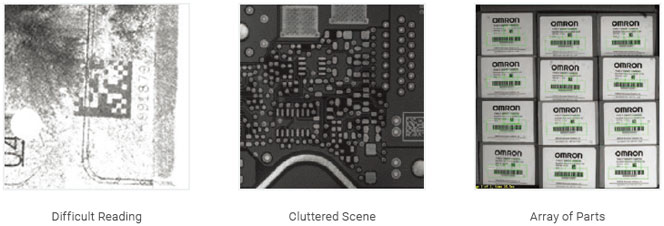

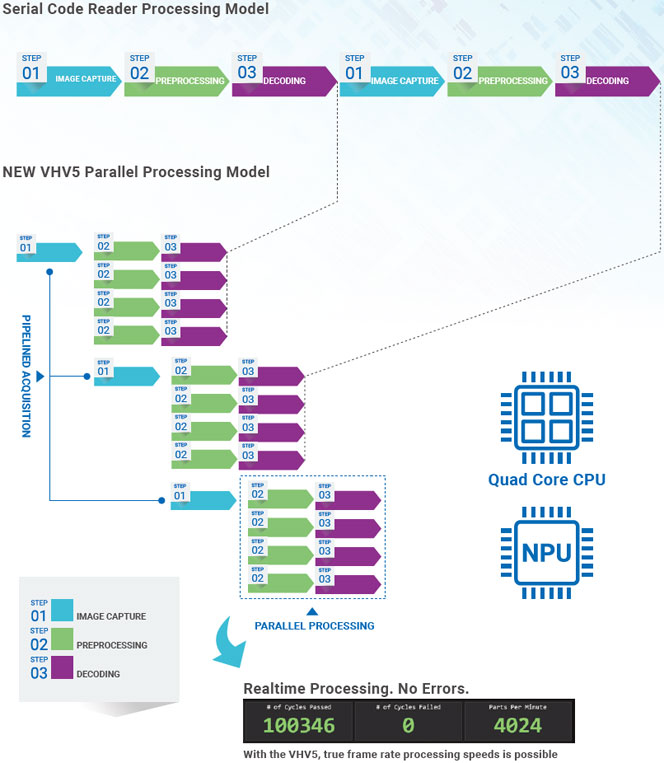

Power - Pipeline Acquisition and Parallel Processing

The most important aspect of the VHV5 is the processing power that it can deliver. The combination of High Speed Sensor, Pipelined Acquisition and Multi-Core Processing leads to robust, non-stop reading on lines at rates of up to 4000 parts per minute.

The processing power can be applied to more than just speed however. It can be applied to:

• Achieving the highest decoding rate for the most difficult to read parts

• Finding and reading codes in very complex and cluttered scenes

• Reading multiple codes, or large arrays of codes in one image

• High rates when using Smart Assist

• Acquiring multiple images over time or distance to find any and all codes that are within them

Power - Pipeline Acquisition and Parallel Processing

Any Operator

OMRON WebLink

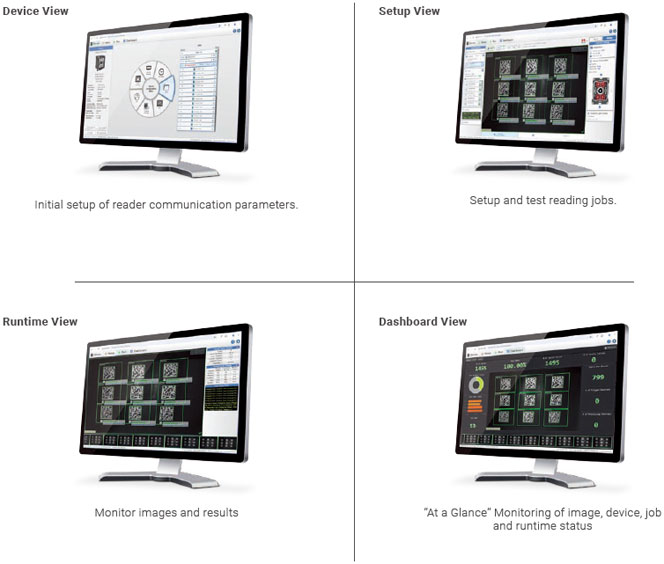

Omron WebLink is a modern Web Based UI, hosted by a Web Server running on the VHV5. The user simply types the IP Address of the reader into any browser to launch the programming and runtime monitoring user interface.

Because the UI and the Reader Application are both installed on the reader, there will never be an issue with version mismatch between a UI which normally runs on a PC, and the code reader firmware.

WebLink provides a simple and intuitive, yet extremely capable User Experience.

The UI allows the user to completely manage the device, and to create, test, run and monitor reading applications. High level functions, tools and advanced visualization are available throughout the UI to automate or guide the user through the setup process.

UX Experience

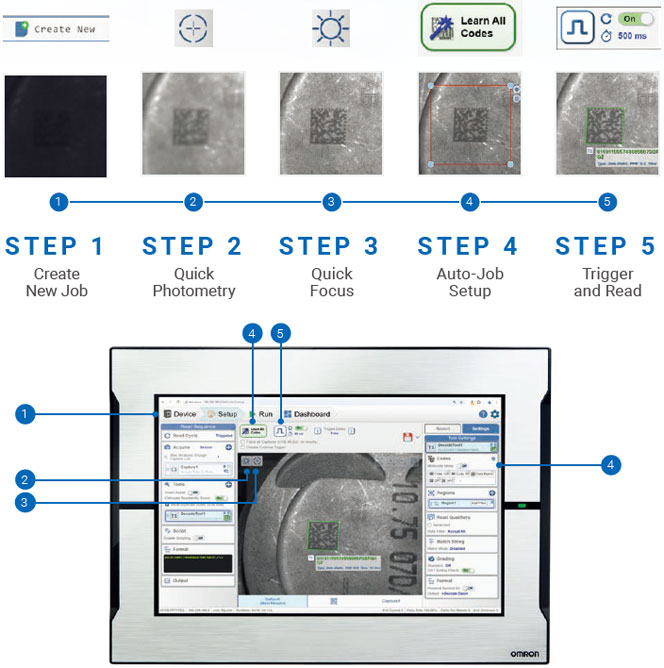

Guided Setup

WebLink has four main views or modes that guide the user through the stages of setting up the reader, programming new reading applications, and monitoring the code reader while running on the production line.

Four Main Views

Device View – Settings Menu

The Device view serves two main purposes, to setup the Device hardware, and to create and manage Reading Jobs.

Device Setup

Device View is used to modify the hardware configuration of the VHV5. Primarily this involves selecting the various communication channels, TCP/IP, EtherNet/IP, PROFINET, RS-232 and Digital IO, that the reader will use to communicate with other automation on the production line. The user can also synchronize the reader with a Master Clock on the Factory Floor.

Job Management

The Jobs entry on the wheel calls up the Jobs dialog. This control is used to create new, and to manage existing reading applications called Jobs.

On Create New, the user specifies one of the 4 standard job types most commonly used in industry. These are Triggered, Continuous Read, Presentation Mode, or Start/Stop. Default settings allow these jobs to be deployed as is, or with very little change.

Each Job is stored in 1 of 32 memory slots in camera. Job can be swapped nearly instantly from trigger to trigger. Jobs can be archived to and from a PC for backup and for sharing across multiple code Readers.

Image Setup - Quick Photometry, Focus, Virtual Trigger

New Jobs created in the Device View are programmed in the Setup View. All Jobs have steps to Acquire Images, to Run Decoding on those images, and then to Format and Output the Read Data. Simple to use High Level functions within Setup View can be used set up each of these steps automatically for the user.

1. New Jobs are created in the Device View

2. Quick Photometry automatically determines the ideal exposure and gain for the image

3. Quick Focus automatically determines and sets the ideal autofocus distance

4. The default Decode Tool is set to read a single code of any type out of the box. If there are multiple codes to be read, Learn All Codes automatically adds and set up all additional Decode Tools for the user.

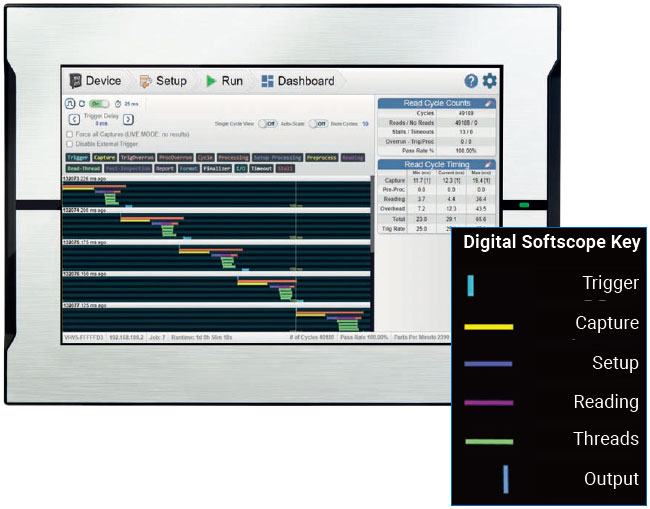

5. The Virtual Trigger allows the job to be tested “live” in setup. It simulates the trigger rate of the production line, and along with the Digital Softscope, allows the user to test the code reading application under full stress.

6. Once satisfied with the job, the system can be put online and monitored with either the Run or Dashboard View.

Learn All Codes

Learn All Codes is a powerful user shortcut designed to simplify the setup of complex reading jobs involving multiple codes in the field of view.

When executed, Learn All Codes automatically detects all the codes in the image and adds a Decode Tool for each one into the job. It then sets key parameters and defines a unique search region (ROI) for each code based on its position in the image, sized to accommodate the expected positional variation of the part during runtime.

Unlike other readers that require manually adding tools, drawing individual search regions, and configuring parameters, Learn All Codes handles these tasks automatically. This reduces the time needed to create complex jobs from minutes to seconds

Result of Learn

• Tools arranged in reading order

• ROIs (Regions of Interest) so each code can be read uniquely

• ROI sized to accommodate the expected positional uncertainty of the part as it runs on the line.

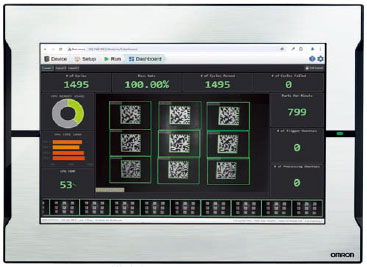

Dashboard View

The Dashboard is a new configurable WebLink runtime view.

It displays images and key data that can be digested in a single glance.

• Main Read Cycle Statistics showing how many parts have run and the read rate.

• Central real-time image display showing read graphics

• Historical Image Filmstrip

• Errors and Warnings

• CPU Operation Stats

The Dashboard View can be programmed by the customer to display 1 of 3 Layouts appropriate for different levels of users

3 Different layout options

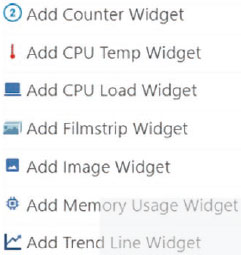

The Edit Layout function allows the user to add and arrange Widgets into and of the 5 main sections or the Dashboard view. It can also:

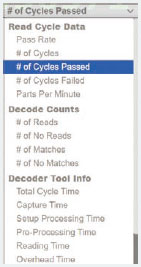

Choose widget type

Choose data to display in Widget

Any Production Line

Part of Any Automation Solution

The VHV5 offers numerous tools and capabilities that make installation, programming and testing of the reader a simple and straight forward task

A full suite of communication options to integrate VHV5 on any line

• TCP/IP – TCP and UDP (both Client and Server models)

• RS-232

• Digital IO

• EtherNet/IP and PROFINET

Simplified PLC Communication

• The VHV5 has one single set of straight forward Input and Output Assemblies used for both EtherNet/IP and PROFINET

• The product is offered with a set of predefined Function Blocks that automate most common operations such as triggering and receiving results

Interactive Setup Mode for Programming and System Tuning

• The camera operates at the same performance level in Setup Mode as it does in

• Run Mode. This allows jobs to be fully set up, characterized and optimized prior to putting them online

• All job and parameters settings made by the user take effect at the next trigger. There is no need to download intermediate job changes to the camera. Programming changes can be seen and evaluated immediately

• Setup Mode offers a built in Trigger Generator for accurate simulation of the reader running on the production line

• Setup Mode provides near real-time image updates, as well as data rich reporting for performance analysis and read cycle tuning

Digital Softscope for Performance Visualization and Optimization

• The Digital Softscope provides an oscilloscope view of the VHV5 while it is running. This allows the integrator to visualize key communication signals and timing data. It displays the Trigger Input, Image Acquisition, Read Processing, and finally Digital and Data Output with microsecond accuracy. This allows the user to:

• Validate the VHV5 handshaking with the controlling host system

• View and optimize the individual read cycle

• View and tune the trigger timing to achieve the maximum sustainable rate

• Visualize error conditions and processing bottlenecks dynamically as the occur

• Run this off line for testing and validation of the reading application before putting the system into production.

• Run this during to monitor for and to debug issues and anomalies

last update: July 1, 2025