Our new self-learning AI automatically executes the repetitive task of learning and result-checking necessary for developing AI detection performance. The system selects the best images for learning, so anyone can build the optimal AI model—no expert knowledge required. This dramatically saves time, not only for initial configuration but also when creating an AI model every time a new product is added.

FH Series

Vision System

New AI feature makes the toughest defect inspection effortless for everyone

- Features

- Lineup

- Specifications

- Dimensions

- Catalog

last update: October 1, 2025

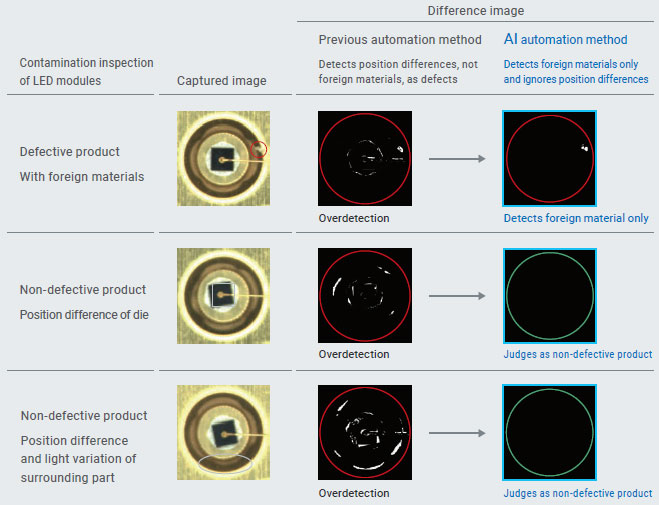

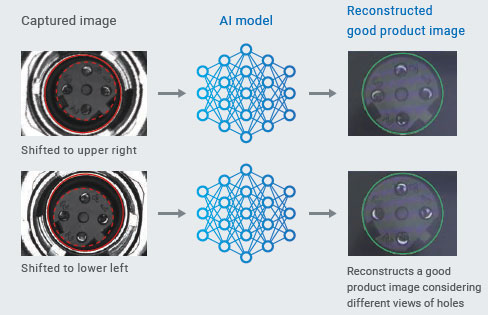

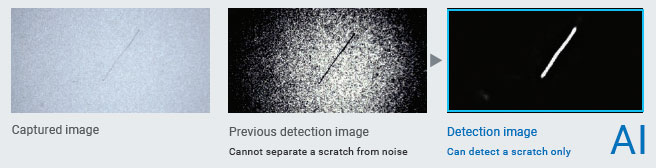

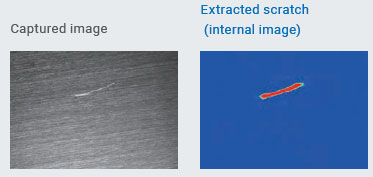

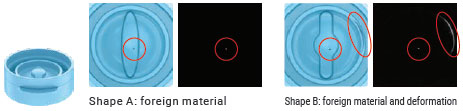

Solve the three main causes of overdetection New AI defect detection algorithm

Extracting just the defects is difficult

1 Shape/color variation

2 Complex background

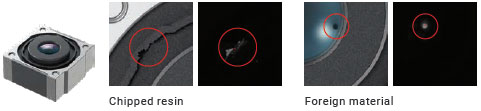

3 Gloss variations

Stably detects just the defects to significantly reduce overdetection

1 Variations in shape or color are ignored, and only blemishes and dirt are detected

2 Weld marks are ignored, and only cracks are detected

3 Gloss variations are ignored, and only chips are detected

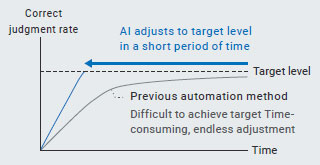

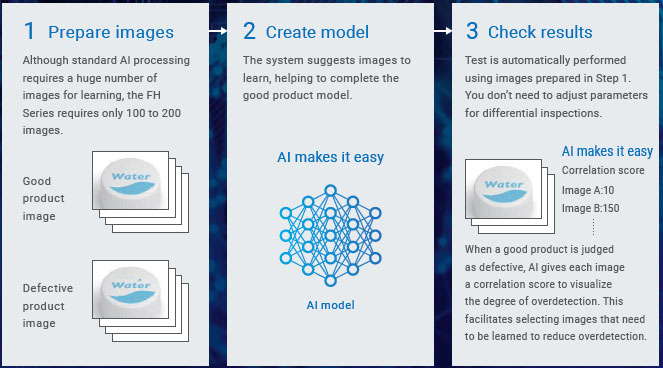

Build the optimal AI model with a single click New self-learning AI

Automates model building, a bottleneck in AI implementation

Auto-adjusts to eliminate overdetection *1

Our new self-learning AI eliminates overdetection by automatically selecting and learning the optimal images.

Trials can be started in no time, even with a limited number of sample images. Furthermore, by using the same sample images, you can achieve the same learning results, ensuring reproducibility for reliable use in manufacturing sites.

*1. Detection rate is for all sample images stored for preliminary learning.

*2. Always the same results for the same dataset

Configuration can be completed in 3 steps

Save maintenance effort with all-in-one solution Implement AI with the tried-and-trusted FH Series

Simple system configuration perfect for manufacturing sites

You can use the AI Defect Inspection feature just by adding its license to your FH Controller.

This allows you to avoid the common irony of AI tool implementation hiking up maintenance costs for image inspection devices.

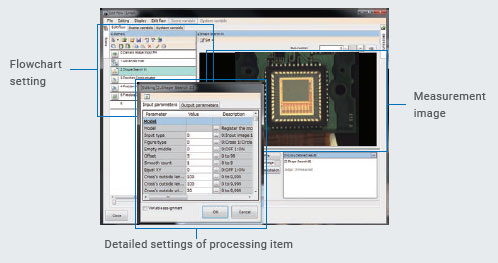

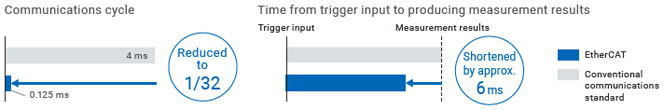

AI and rule-based processing can be included in same inspection flow

Flow chart UI enables flexible design

AI processing can be easily added to your existing inspection flow, allowing you to make effective use of your assets.

Example: Appearance inspection of IC chip

Enables quantitative judgment in AI inspection

Quantitatively accounting for AI inspection results can be difficult. This new function enables you to quantify the defects by incorporating rule-based inspections, allowing for easily explainable judgments.

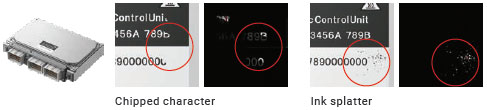

AI Defect Inspection Solutions

With AI Defect Inspection, stable detection can be achieved with simple training for cases that conventional image processing has struggled to distinguish between non-defective and defective products, leading to over-detection.

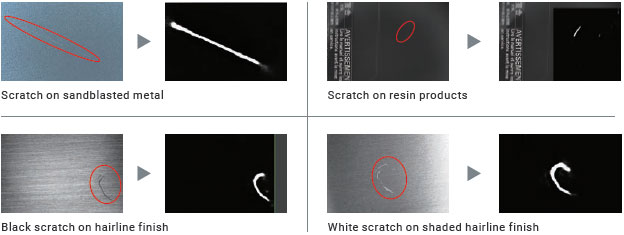

High-speed, large-capacity controller supporting AI-powered and standard inspections

*1. The FH-555[] Controller is compared with the our previous model FH-3050 Controller.

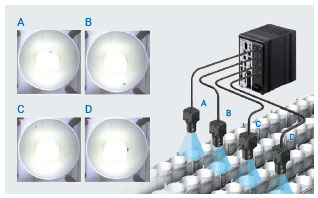

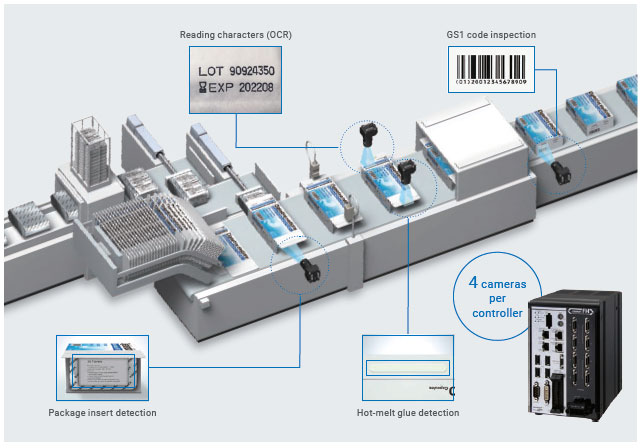

Four-core parallel processing examples

Multi-Line Random-Trigger inspects at up to four different timings

A single controller can perform inspections at different points at different timings.

Controllers installed for each process can be integrated into one, reducing initial costs and saving space.

Packaging process of pharmaceuticals

Contamination inspection of beverage containers

A single controller that can control each line saves initial costs and space.

Appearance inspection of rechargeable battery cells

Four cameras can be connected to one controller, enabling simultaneous inspection of dents and scratches from four directions.

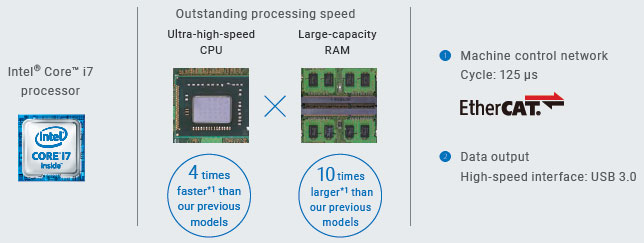

Camera and light for high-speed, high-resolution visualization

High-resolution 20.4 megapixel camera

We offer a range of cameras that can capture high-resolution images suitable for sensory inspection at high speeds.

Ultra-high-speed sensing technology in a compact design

There was a trade-off between high-resolution image capture like the human eye and inspection processing speed. We use new CMOS image elements and dual transfer technology to capture high-resolution images while transferring images at high speeds. This facilitates applications that previously required multiple cameras or a mechanism to move a camera.

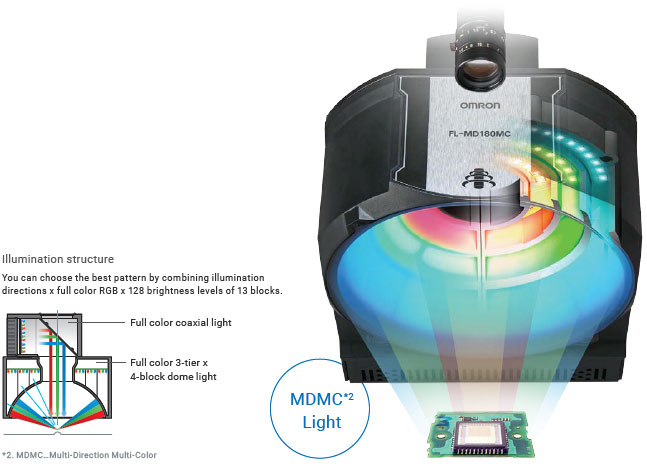

MDMC light with flexible lighting patterns

This light can be adjusted to defects by combining the illumination colors and angles like humans do. Even if new objects or inspection items are added after installation, there is no need to add or change the light—just change the illumination pattern. The illumination patterns can be registered as settings, facilitating duplicating production lines.

*1. MDMC...Multi-Direction Multi-Color

Illumination structure

You can choose the best pattern by combining illumination directions x full color RGB x 128 brightness levels of 13 blocks.

SWIR camera for infrared inspections

OMRON’s SWIR camera has adopted a Sony image sensor (IMX990/IMX991) that enables broad-range imaging from visible light to 1,700 nm wavelength, allowing for both visible light and SWIR inspections in a single unit. It can expand the supported range of inspected objects and applications, while ultimately reducing inspection system costs and increasing the image processing speed.

Unique heat-dissipating structure and front-reinforced heat sink [Patent Pending]*2

The camera has a special heat dissipation design so that it can operate stably even with natural cooling using the heat dissipation of the individual camera without using air cooling or water cooling.

The special heat sink at the tip of the camera prevents heat from being trapped and helps to dissipate heat efficiently, and the heat dissipation block in the center of the individual has a mechanism to evenly dissipate heat from the element.

*2. “Patent pending” and “Patented” refer to patent status in Japan (as of September 2025).

Examples: Inspections difficult to conduct with visible light

Aligning silicon wafers

High-precision alignment is possible with an alignment mark image captured by the camera through a wafer.

Inspecting the leakage of transparent liquid

Stable inspection is possible by visualizing transparent liquid that cannot be captured by a standard camera.

Software for flexible automation

Flexible image capture

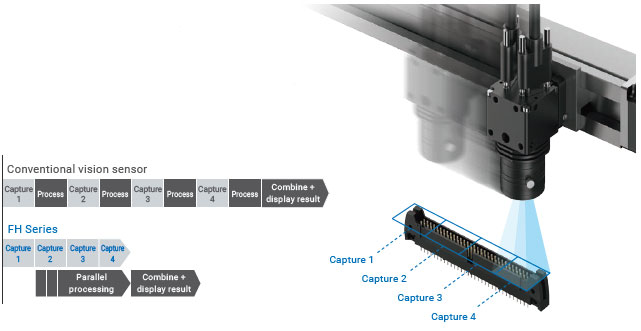

Multi-Trigger Imaging captures long objects at high speeds

The Multi-Trigger Imaging function can capture images and process them in parallel, leveraging the speed of the multi-core processor to capture long objects at high speeds.

High-resolution inspections by trimming, resizing, and integrating captured images

This feature allows inspection with a high-resolution image by continuously extracting and combining images captured by an area camera, which is easier and less costly than using a line camera.

External inspection of cylindrical workpieces

The external appearance of a cylinder can be inspected all around with an image without distortions or unevenness by extracting and combining curved surface images with minimum distortions.

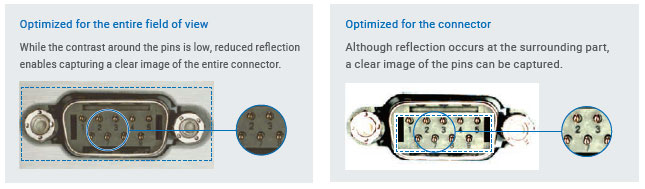

Camera Image Input HDR optimizes contrast

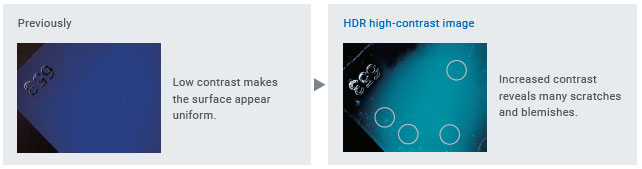

Camera Image Input HDR helps create optimized HDR images under variable ambient conditions. Once you specify the optimum area to capture on the image, the FH Series automatically adjusts the shutter speed while capturing images and combining the images.

Adjusts brightness to suit your specified area

Detects low-contrast defects in high-contrast mode

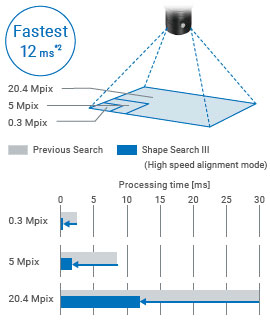

High-speed, high-precision positioning

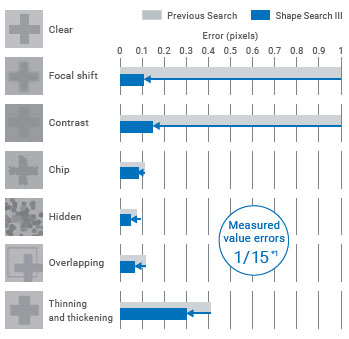

Shape Search III is robust against shape variations

High-precision and robust positioning is possible even under the adverse conditions, such as changes in environments and materials.

*1. The value measured under our specified conditions is provided for reference.

A 20.4 Mpix camera can search a positioning mark in as fast as 12 ms*2, and a 5 Mpix camera, widely used for alignment applications, in as fast as 2 ms.

*2. The value measured under our specified conditions is provided for reference. 20.4 Mpix camera.

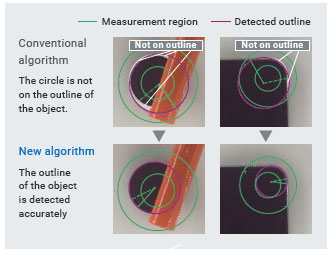

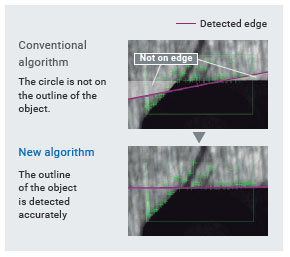

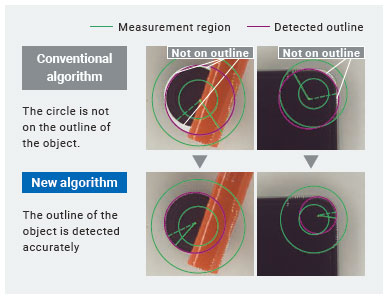

Circular Scan Edge Position accurately estimates the center and radius of a circle

The new algorithm accurately detects a whole circle from a part of the circle.

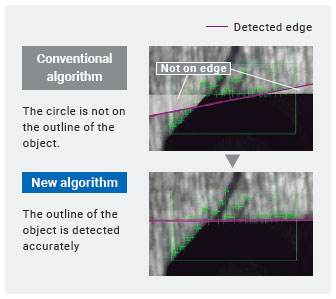

Scan Edge Position removes noise to detect edges

This algorithm accurately estimates lines even when the edges are unclear due to variations in objects or disturbance.

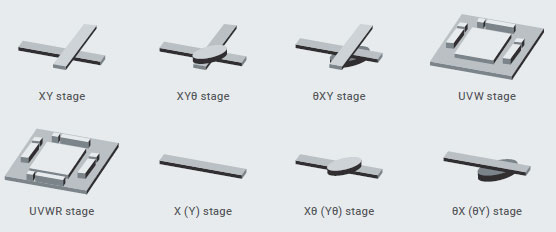

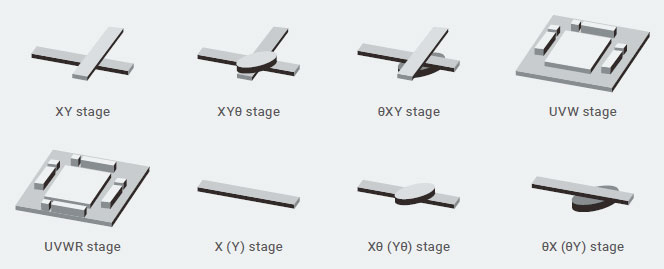

Stage Data calculates for various stages

The popular single axis + θ axis stages as well as UVW stages can be used. The use of the same axis for both handling and positioning simplifies machine configuration.

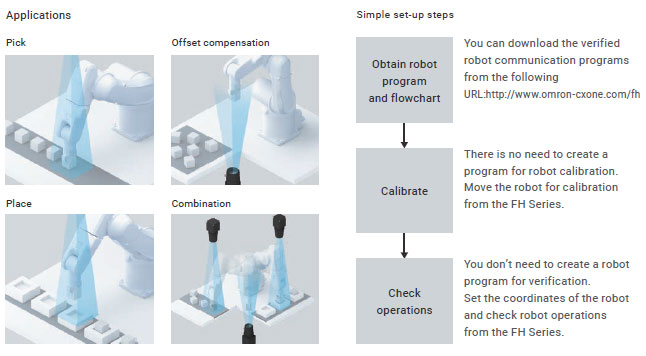

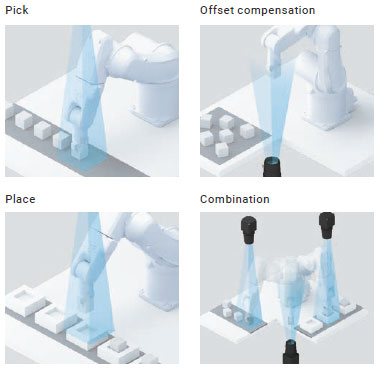

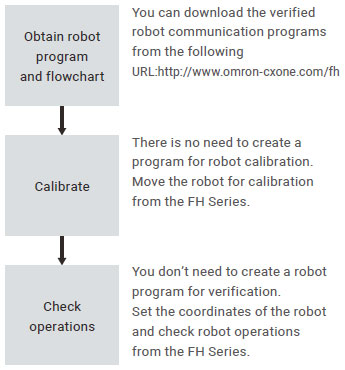

Robot Setting Tool simplifies connecting robots

Communication programs to connect robots from various vendors and FH flowcharts required for robot applications are provided free of charge. You can quickly set up robot vision applications.

Applications

Simple set-up steps

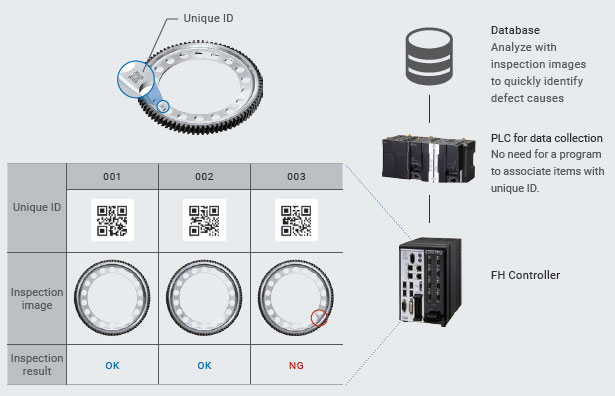

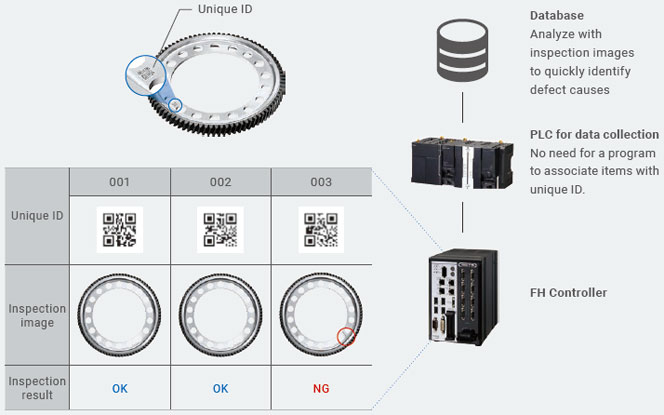

Unique identification and quality control

Unique ID associated with inspection image and result

The FH Series can associate a unique ID with the inspection image and result, and then output them to the host device.

You can immediately find required inspection images and quickly identify causes of fails.

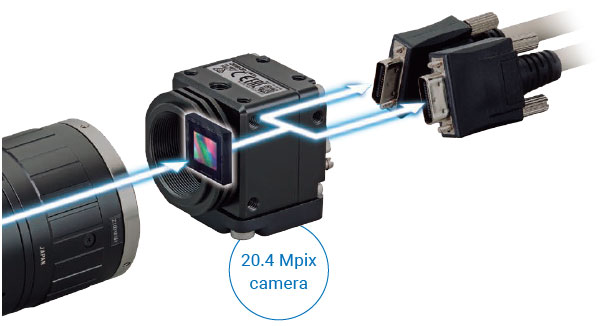

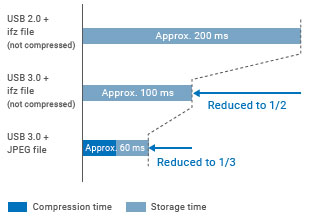

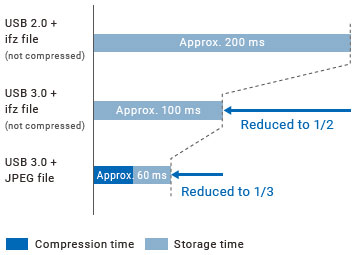

High-speed image storage

The amount of inspection image data required for defect cause analysis can be so large that conventional controllers are unable to store it given their storage time and capacity constraints.

The high-speed, large-capacity controller has USB 3.0 ports and the improved algorithm to compress image data at high speeds, enabling all images to be stored to meet increasing needs in quality control.

The times in the figure below provided for reference only and their accuracy cannot be guaranteed. They are measured under the following conditions:

● FH-5[]5[] Controller

● 5 Mpix monochrome images

● Size of converted JPEG file: 0.6 MB

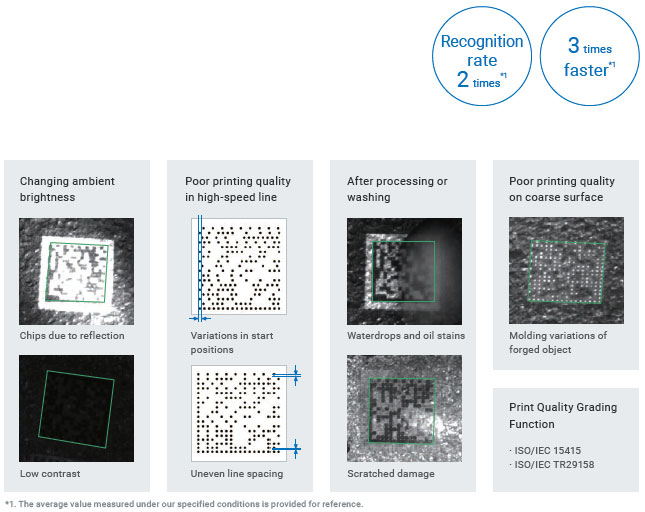

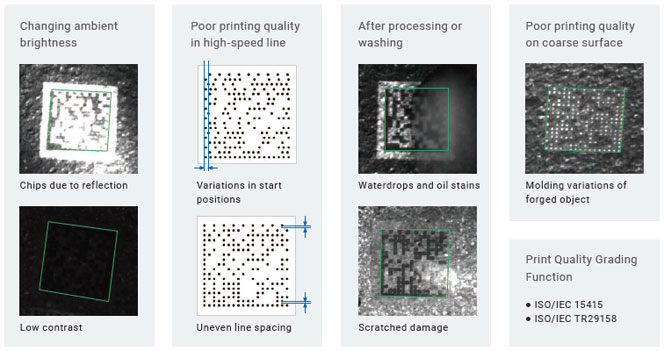

2D Code II provides powerful code reading

The FH Series incorporates a dedicated algorithm for reliable and fast 2D code reading even under variable ambient brightness or adverse conditions such as after processing or washing.

It also supports reading “DMRE codes”, symbols created by extending the rectangle DataMatrix code symbol size.

*1. The average value measured under our specified conditions is provided for reference.

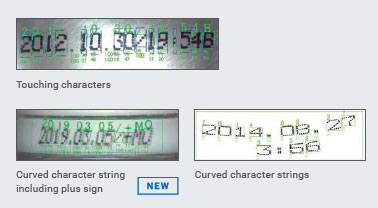

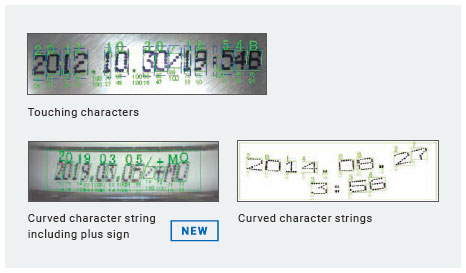

OCR reliably reads difficult-to-read characters

OCR can reliably read characters printed too close to each other or on curved surfaces. Also plus signs can be read.

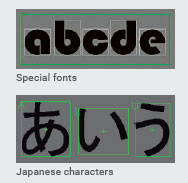

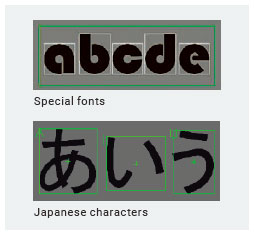

Character Inspection reads special fonts

Character Inspection recognizes special fonts and non-alphanumeric characters based on pattern search using the dictionary set up by the user.

Design interface for quick setup

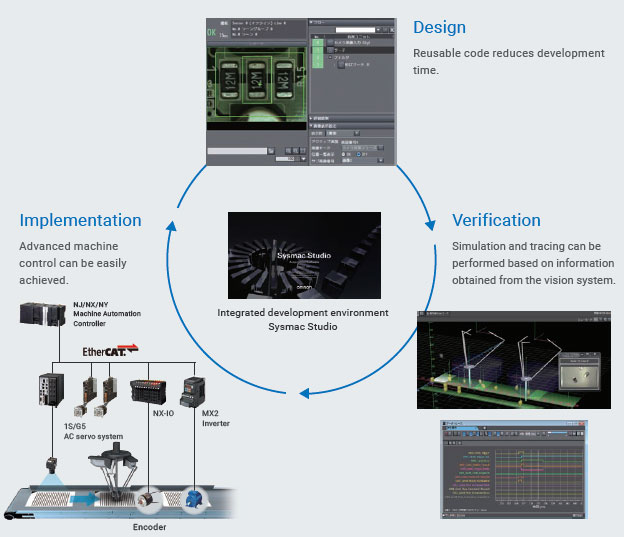

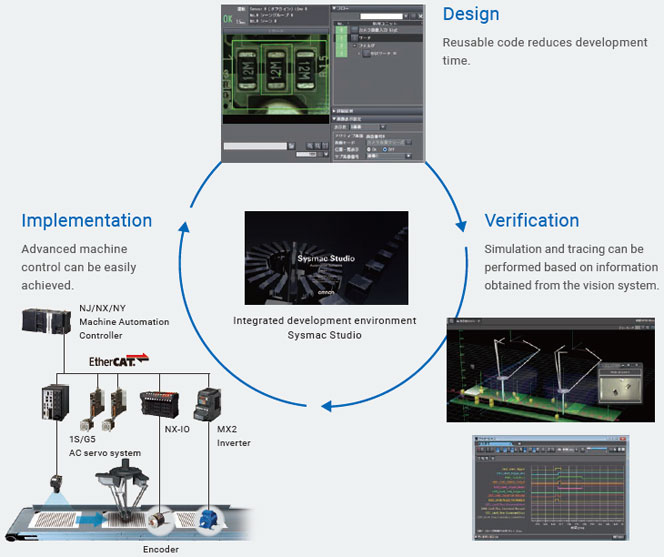

Integrated development environment Sysmac Studio

Sysmac Studio is a unique environment that integrates logic, motion and drives, robotics, safety, visualization, and information technologies in a single project, thus reducing the learning curve and the intra-operative software costs.

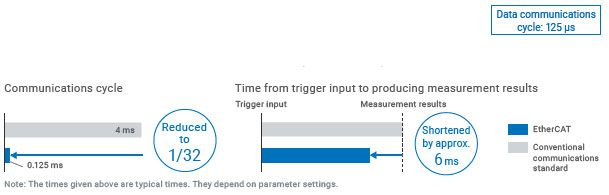

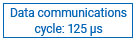

EtherCAT® for high-speed data transfer to control various devices

You can use EtherCAT® to connect NJ/NX Machine Automation Controllers and 1S/G5 AC Servo System to increase the control speed of everyday communications protocols from position detection to starting axis motion.

Note: The times given above are typical times. They depend on parameter settings.

Total Design Management Editor simplifies complex processing design

This design interface includes pre-installed screens for all phases, from design through to setting and operation.

Just select processing items and determine the order to manage variables. Time-consuming calculations and inputs are no longer required.

Easy setting

All the common settings of multiple scenes can be made at once. Simplified inspection flowcharts reduce setting errors and prevent from forgetting to change settings.

Efficient setting

To inspect aligned parts, the FH Series can repeat the same measurements while shifting the measurement region within the same image. This reduces setting times.

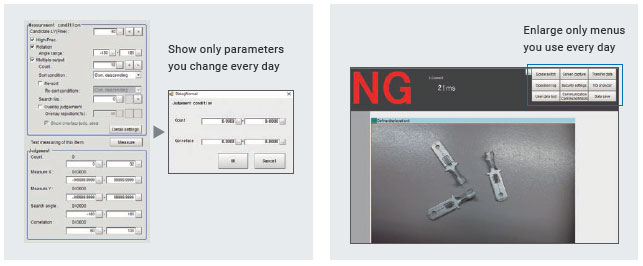

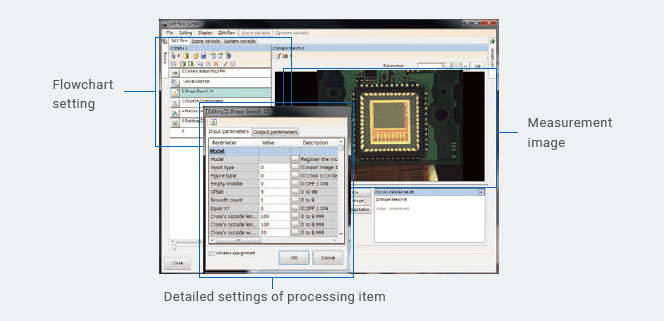

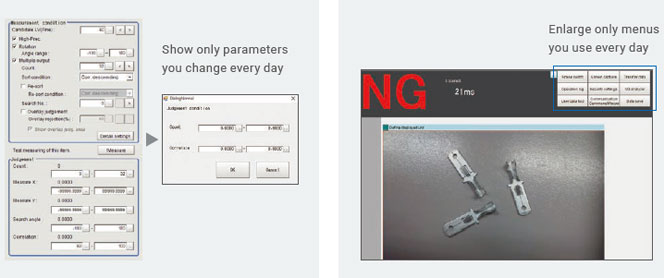

Customizable user interface simplifies operations at production sites

Showing only necessary screens for production makes the interface easier to use. Screen layout can be customized just by selecting and placing objects, without programming.

last update: October 1, 2025