A new fiber amplifier unit able to detect the “presence or absence” of workpieces with “solid stability” at a “Cost-effective price” is now available.

E3X-ZV / MZV

Smart Fiber Amplifier Units

Solidly Stable Presence/Absence Detection at an Amazing Price

- Features

- Lineup

- Specifications

- Dimensions

- Catalog

last update: January 5, 2023

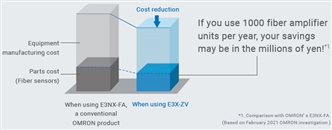

“Cost-effective Price” × “Stable Detection”

Contributes to reducing your equipment cost

New technologies and efficient design allow cost reduction in manufacturing process.

Since fiber sensors are used in large quantities, E3X-ZV makes a huge contribution to reducing your equipment cost.

Reliable detection performance

Providing most relevant functions and keeping best performance to detect presence or absence,

E3X-ZV can be used as-is in your equipment.

[Cost-effective Price] “Cost-effective Price” achieved by carefully selecting the functions and performance required to detect presence or absence

Fiber sensors are used in large quantities in parts feeders, roll presses for secondary batteries, assembly machines for digital products, and so on to detect the presence or absence of workpieces. However, many customers are using fiber amplifier units with excessive functions and performance that may make them accordingly costly.

OMRON narrowed down functions and performance to those required to detect presence or absence, and optimized the materials used as well as the production process in addition to making full use of new technologies to achieve a Cost-effective price. The more you use the more cost savings you gain, making E3X-ZV a fiber amplifier unit with the best cost performance.

Three new technologies that enable “Cost-effective”

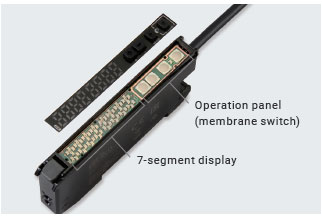

Integrated display and operation panel [Patent pending] *1

Material cost is reduced by mounting the 7-segment display and operation panel on one substrate.

Furthermore, “membrane switches” are used for operation buttons to achieve both cost reduction and improved click feeling.

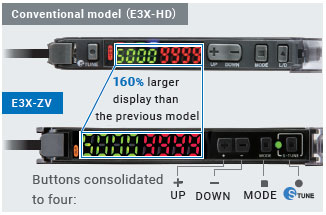

Revised user interface

The L/D (Light on / Dark on) button present on conventional models is eliminated, reflecting customer opinion that the button is rarely used and is a cause of malfunction by accidental pressing.

This helped not only to reduce material cost, but also to enlarge the display and increase visibility.

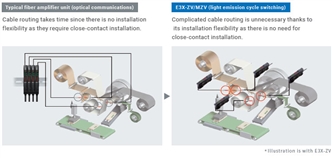

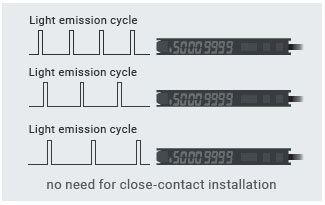

New mutual interference prevention function

Adopting the mutual interference prevention by light emission cycle change eliminated the optical communications function between amplifiers required in previous methods, and reduced the material cost.

Furthermore, this method allows the activation of the mutual interference prevention function without needing the fiber amplifier units to be installed in close contact with each other.

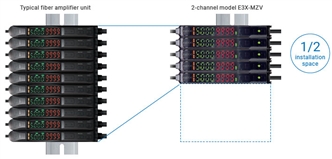

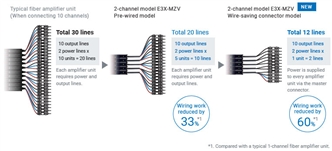

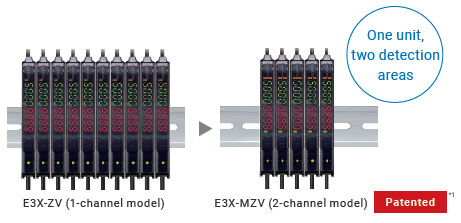

2-channel model option to attain the ultimate cost effectiveness

The 2-channel model equipped with amplifier functions for two fiber amplifier units enables substantial purchase cost reduction since the required number of units is halved. Furthermore, it greatly contributes to the downsizing of equipment and control panel in addition to allowing substantial reduction in wiring workload and power consumption.

*1. “Patent pending or Patented” indication means patent is pending or is patented in Japan. (As of February 2021.)

[Stable Detection] Reliable detection performance

E3X-ZV is equipped with functions and performance for reliable use in a wide range of equipment.

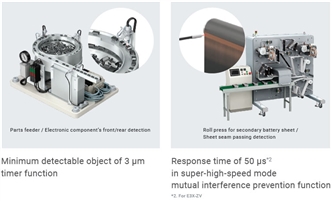

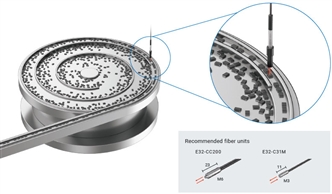

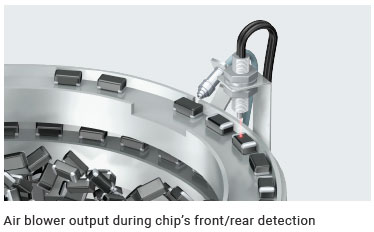

Microscopic object’s front/rear detection in parts feeders

3-μm minimum detectable object enables the stable detection of microscopic chips as well

With a detection performance equivalent to that of E3X-HD and a minimum detectable object of 3 μm, E3X-ZV has sufficient margin to detect small parts and the size of metallic parts of electronic components used to determine their front or rear.

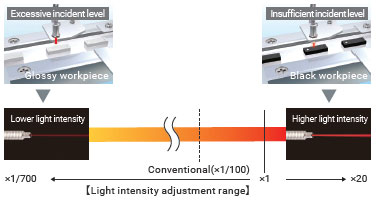

Resistant to differences in color and surface conditions

With high dynamic range (seven times that of E3X-HD), E3X-ZV stably detects from black to glossy objects.

Light saturation is avoided, even when the background is a glossy surface, by sufficiently lowering the light intensity.

Stable output by timer function

E3X-ZV is equipped with ON/OFF-delay and one-shot timer to enable output control even in an environment without PLC.

Seam detection in roll presses for secondary battery sheets

50-μs*1 response time in high-speed mode enables the stable detection of workpieces moving at high speed

With a response time of 50 μs, equivalent to that of E3X-HD, E3X-ZV captures seams on fast moving sheets without fail.

Given a 10-mm wide electrode, it can theoretically detect seams also on sheets moving at 200 m/s.

*1. For E3X-ZV

Mutual interference prevention function that does not need close-contact installation

The mutual interference prevention function based on different frequencies prevents mutual interference among up to four channels.

Wiring the fiber units and cables is also easy since the fiber amplifier units need not be installed in close contact with each other.

Functions welcome when using in large quantities

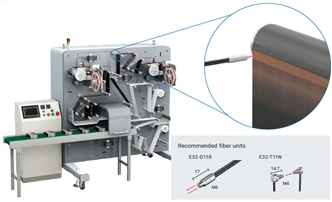

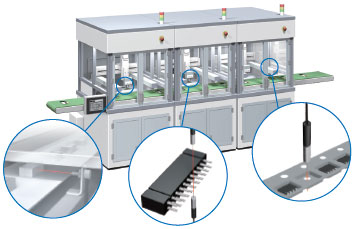

Presence/absence detection in automatic assembly machines

Easy tuning to reduce tuning workload

Adjustment of light intensity and threshold level to their optimal value is possible by just pressing the button twice. The operation is common regardless of the workpiece or installation conditions, allowing for a unified setting method that eliminates variations owing to operators.

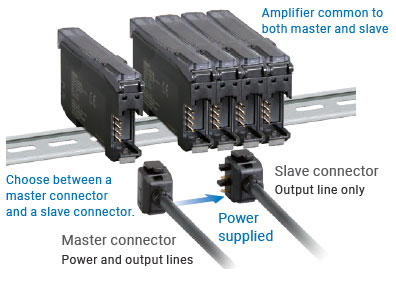

Wire-saving connector model to reduce wiring work [NEW]

Power supplied from the master connector simplifies wiring; just wire the output line when connecting the slave connector. Amplifier units can be replaced easily without the need for rewiring. The amplifier unit can be used as both master and slave, enabling standardization on a single model.

Only a disconnected connector needs to be replaced without replacement of the amplifier unit and reconfiguration after replacement. This reduces maintenance time and replacement costs.

1/2 installation space with 2-channel model

The 2-channel model equipped with amplifier functions for two fiber amplifier units can halve the installation space. This helps miniaturize not only machines, but also power supplies because the power consumption will also be reduced by approximately half.

2-channel model for simplifying wiring

Wire-saving connector model for drastically reducing wiring

The use of the 2-channel model can reduce wiring by 33% *1.

The wire-saving connector model allows further reduction in wiring.

Three on-site work-saving functions that also contribute to labor saving

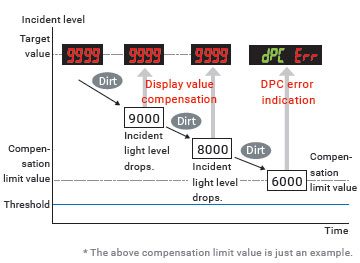

No need to re-tune even if the incident level decreases

DPC function (Dynamic Power Control)

Decrease in incident level due to LED deterioration or dirty fiber unit is detected to compensate and bring it to the level at the time of tuning to save you the trouble of re-tuning. It is particularly useful when working with through-beam or retro-reflective models.

No need to make business trips to sites to explain operations

Operation buttons with symbols

Since buttons are indicated with +, −, □, and ◯, operation can be easily transmitted over the phone, enabling remote support.

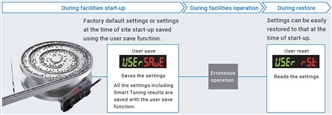

Hassle-free recovery also from erroneous operations

User save function

Saving the factory default settings or settings at the time of site start-up using the user save function saves all information including the tuning information. If during operation, a fiber amplifier unit needs to be restored to the saved settings as a result of an erroneous operation by a site operator, this can be done easily and on-site by instructing a user reset. Contents saved by the user save function are not cleared by the setting initialization.

last update: January 5, 2023