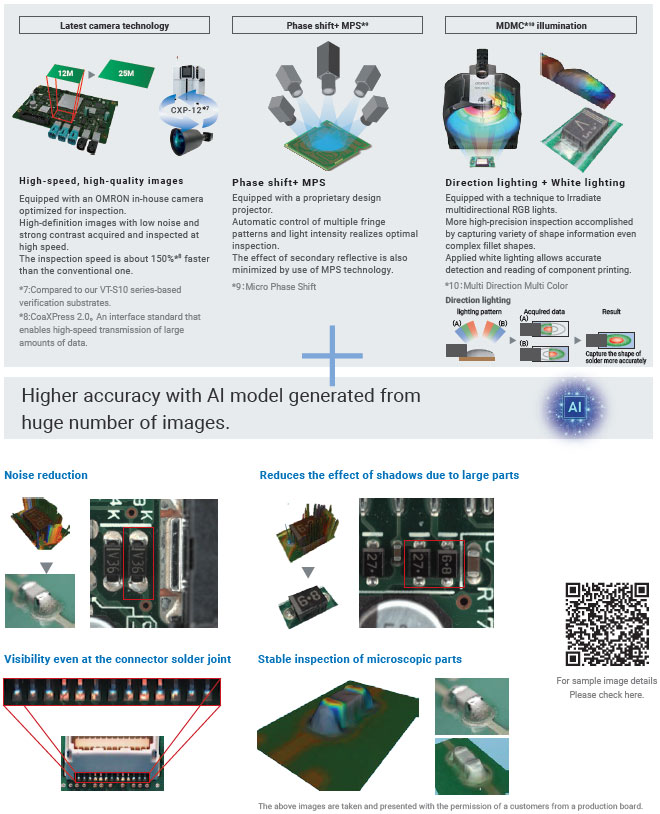

*6: Excellent filtering of noise that effects the judgement of inspection results such as shadows, secondary reflections, abnormal defect shapes and other uncertain factors.

VT-S1080

PCB Inspection System

Innovating manufacturing through Omron advanced inspection technology

- Features

- Lineup

- Specifications

- Dimensions

- Catalog

last update: April 15, 2024

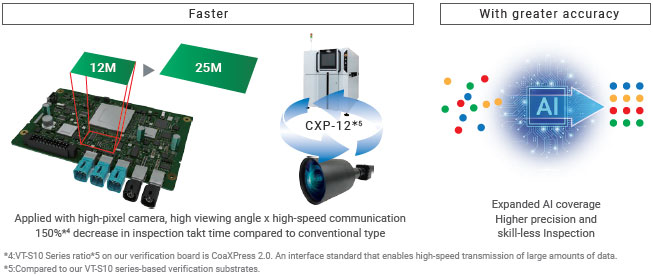

Remove takt time bottlenecks and reduce operator related steps and man-hour related inspections.

High-precision solder shape reconstruction helps achieve zero defect products

The combination of Omron's own patented technologies achieves highly robust*6 and reliable inspection performance.

Minimization of programming efforts by quantitative inspection and AI-assisted qualitative inspection

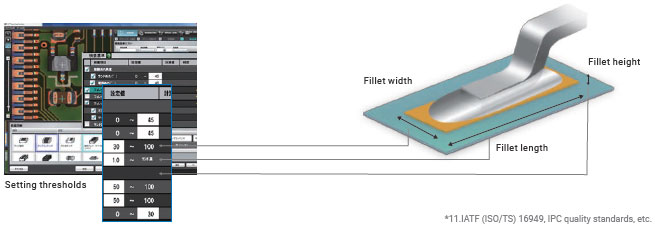

Quantative inspection is compliant with international standards*11

Directly set machine inspection criteria is based on international standards applied as inspection criteria, it doesn’t rely on the skill and expertise of the programmer.

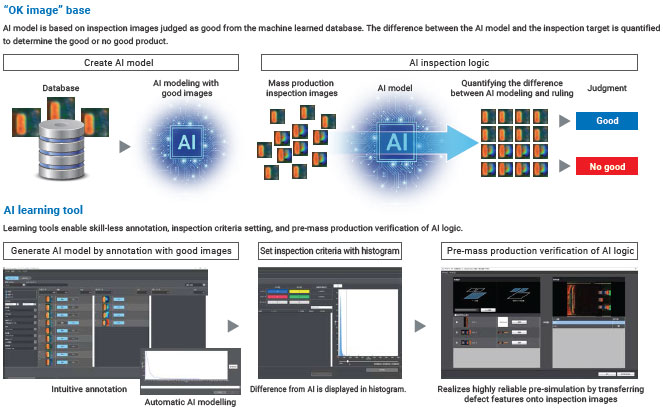

AI inspection logic that reduces man-hours dependent inspection

Omron has been developing a variety of reliable AI tools to address customer concerns such as defects going undetected and/or managing large amounts of machine learning data when using AI for inspection. AI judgement makes inspection more less skilled dependent and it contributes to the improvement of production by enhancement of detection and reduction of false calls or visual checks.

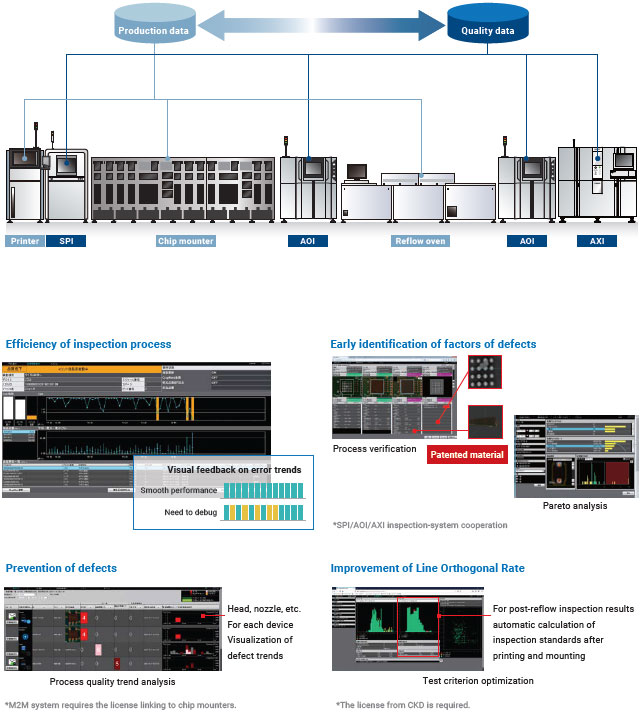

Maximizing good-quality throughput by using quality focused, M2M system

M2M system

To optimize the quality and equipment operation status without human intervention, made possible by enabling autonomous communication and exchange of information between various connected, production equipment.

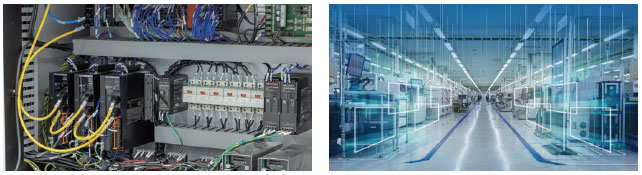

Zero down time production line with equipment monitoring and predictive maintenance

Equipped with Omron control hardware technology, this system allows real-time collection of information from all the IoT connected devices inside the inspection equipment. It allows the equipment status to be visualized, enabling predictive maintenance and quality traceability.

last update: April 15, 2024