The K7TM Heater Condition Monitoring device can measure the resistance values of resistive heaters properly and periodically allowing for heater condition and trend monitoring both on site and remotely.

K7TM

Heater Condition Monitoring Device

Predictive maintenance by monitoring heater condition

Software Download

You can download software for the K7TM-A2.

- Features

- Lineup

- Specifications

- Dimensions

- Catalog

last update: May 27, 2024

Appropriate heater conditioning monitoring ,independent from temperature control method, heater temperature characteristics, and location

Eliminating heater burnout reduces unplanned downtime, profit loss from yield issues and replacement part costs

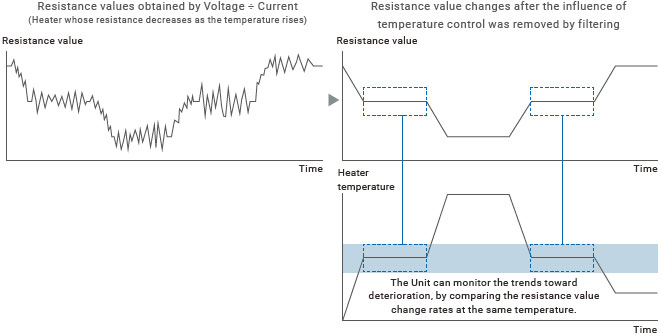

Heater resistance value trends are not able to be determined using the basic voltage/current calculation since the temperature controller and heater characteristics influence this calculation. The K7TM is able to measure the resistance values regardless of these influences by filtering them out of this calculation. Additionally, the K7TM is able to monitor the deterioration trends in heater resistance by comparison with historical resistance values when used in the same environment.

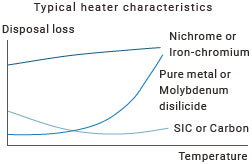

Heater temperature characteristics

Depending on the type of heater, the resistance value may vary greatly depending on the temperature. Heater temperature characteristics need to be considered in order to monitor proper heater deterioration trends. Therefore, it is necessar y to constantly monitor the heater resistance value at the same timing as the heater temperature.

[Measurement method in K7TM]

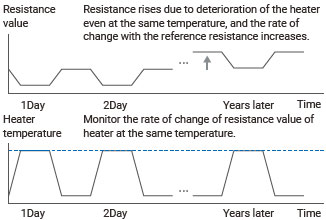

K7TM calculates the rate of change of the resistance value (reference resistance value changerate) from the resistance value (reference resistance value) when replacing the heater and the cur rent heater resistance value, and utilizes it as an indicator to measure the degradation trend.

[Changes in heater temperature and resistance (Long Term)]

Since the temperature is controlled, the temperature of the heater is constant, but the resistance of the heater increases with deterioration.

Collecting measurement data remotely using network connections

Easy to retrofit onto existing equipment

Condition monitoring can be achieved by using a CT clamp on the power line of the heater and connecting voltage lines to each side of the heater.

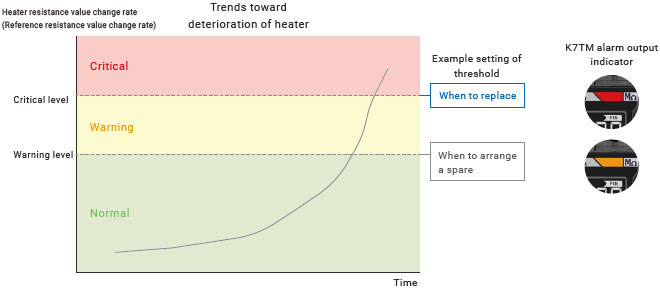

Predictive maintenance that quantifies the deterioration state of the heater

By converting condition of the heater into a numerical value called the rate of change of the heater resistance value, scheduled maintenance based on the numerical value becomes possible. It also enables maintenance of heater equipment that does not depend on skilled personnel.

Ready to perform maintenance based on the degree of deterioration from heater resistance values

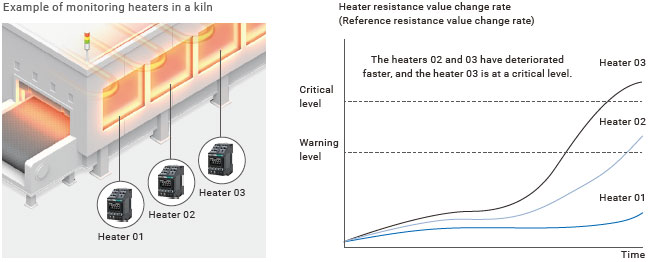

The K7TM can monitor the state of the heater by the rate of change of the heater resistance value and monitor the state and tendency of each heater, so it is possible to determine when replacement is necessary, so it is unplanned while utilizing the remaining life of the heater. You can reduce the possibility of downtime. In addition, maintenance that does not depend on skilled people becomes possible.

Using reference Resistance Value Change Rate to determine replacement.

Previously there were challenges in determining correct service and replacement time on heater equipment. Since the K7TM can capture deterioration trends in heater resistance values change rate and trigger alarms when a threshold is reached, the user is able to determine the optimal time to service or replace heater equipment.

value. The Unit cannot capture the deterioration due to other factors.

Note 2. Set an appropriate threshold that suits your environment as the trends toward deterioration of heater may vary

depending on the heater type and the use environment.

last update: May 27, 2024