The LEDs mounted on the head unit need to be replaced regularly when their life ends. If you cannot receive support abroad from the manufacturer, you need to procure parts or arrange repairs and troubleshooting as well as regular replacement remotely from your country. This may interfere with local production. OMRON provides the same level of supply and support for the ZUV Series anywhere in the world including Asia Pacific and Greater China. You can reliably use the ZUV Series in overseas factories without compromising productivity and quality.

ZUV Series

Smart Curing System

Anywhere in the world

- Features

- Lineup

- Specifications

- Dimensions

- Catalog

last update: May 16, 2022

Local procurement at overseas factories

Sales network of around 150 locations in 40 countries and regions

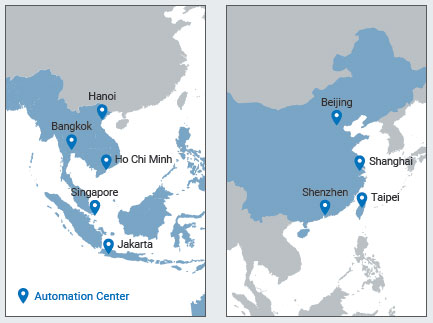

9 Automation Centers in Southeast Asia and Greater China

In Southeast Asia and Greater China where many assembly factories for the world are based, OMRON helps with overseas expansion at its country headquarters and 9 Automation Centers*2 that demonstrate control applications using latest automation devices.

Please visit the Global Network for the latest information.

https://www.ia.omron.com/global_network

*1. As of March 2020.

*2. 35 Automation Centers are located around the world. As of February 2022.

Cross-border Support – Consultation Desk arranges your service request to be carried out Globally –

OMRON account manager pass your request to our Consultation Desk, which Will allow you to use our technical service without constraints of various procedures, languages and borders.

17 years of experience in providing UV LED curing systems (as of 2022)

OMRON was one of the first to exploit the advantage of the UV LED light source and released its first curing system with UV LEDs which replaced lamp irradiation systems, the ZUV Series, in 2005. With the extended variety of heads, lenses, and controllers, the ZUV Smart Curing System became the most popular curing system with UV LEDs in Japan in 2007.*3 Now in 2022 OMRON is manufacturing the ZUV Series at its own factory and has a proven track record of selling the ZUV Series in various countries around the world since its release in 2005.

*3. Based on 2009 LED related market research issued by Fuji Chimera Research Institute, Inc. on March 12, 2009.

Meeting diverse UV curing needs

Five spot sizes for reliableUV bonding

UV irradiation using a standard head and spot lens is recommended for general UV curing. The UV irradiation area size can be changed simply by replacing the head lens. You can choose the best spot size for the workpiece from five lenses with different spot diameters, enabling reliable curing of UV adhesives.

Reduce tact time and footprint by combining lens and head

Line beam lens for large area curing

The lens with a wide beam width provides relatively uniform elliptical irradiation. This enables UV curing of even previously difficult workpieces with a single irradiation.

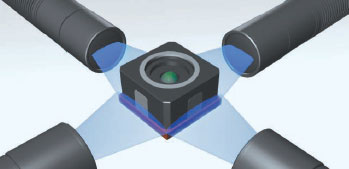

Bonding of camera module housings to substrates

UV curing across a wide area using four heads with the line beam lens reduces tact time.

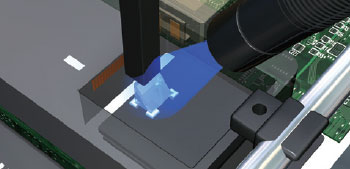

Diffuse illumination head x diffusing lens for curing at a distance

This combination maintains the irradiation power of 800 mW/cm2 for curing even when the head is 30 mm away from the workpiece. This solves the problem that irradiation cannot be performed close to the workpiece.

UV bonding of optical pickup prisms

Diffuse beam irradiation enables UV curing with a working distance of 30 mm.

Ultra light focus lens for quick curing

The use of the ultra light focus lens with a spot diameter of 2 mm achieves maximum irradiation of 13,200 mW/cm2 *1. Strong irradiation power allows fast curing.

Bonding of needles to syringes

High-speed UV curing with the ultra light focus lens shortens tact time of the bonding process.

*1. Under the following conditions: 100% irradiation power, 25°C room temperature, and with heat sink. Values for reference only.

Side-view lens for irradiation in small spaces

The head with the lens that delivers irradiation at right angles to the head only needs about 1/7 of the installation space of the standard head with the spot lens. Installation flexibility enables UV irradiation in narrow spaces.

Minimization of rear space

Installation space of production equipment can be effectively used. This lens is also suited to retrofitting in confined spaces in existing machines.

Long life reducing operating costs

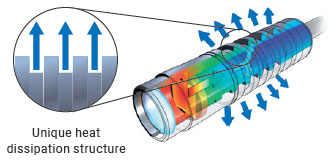

Reduce replacement frequency of light source with unique heat dissipation structure

The life of a UV LED can be shortened if the heat from the LED cannot escape. All the ZUV Heads use OMRON's unique heat dissipation structure to avoid rise in temperature during light emission, having a long life and reducing replacement frequency of their light source.

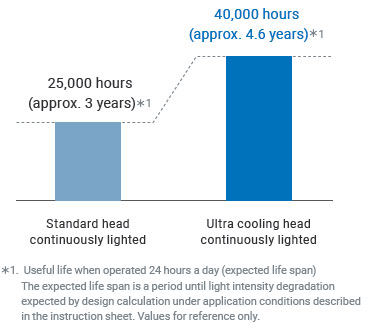

Significantly cut operating costs with ultra cooling head

The ultra cooling head can be used for about 4.6 years which are longer than the standard head, greatly reducing operating costs.

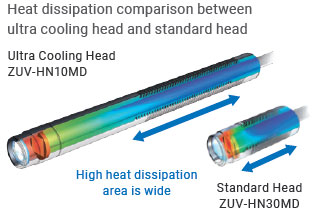

Long body for super-long life

The ultra cooling head has a long body where the number of heat dissipation ribs was increased from 21 of the ZUV-HN30MD Standard Head to 40.

Extensive heat dissipation achieved 1.6 times longer life than the standard head and more stable irradiation intensity.

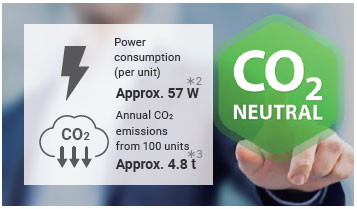

Lower CO2 emissions through reduced power consumption

The highly stable UV LED light source is designed to save power by turning ON when needed. This can significantly reduce not only electricity costs but also CO2 emissions, contributing to carbon neutrality. In addition, the LED light source that does not use mercury reduces environmental impact.

*2. Power consumption may vary depending on device conditions.

*3. It was assumed that the head was operated 24 hours a day for 260 days and ON time/equipment operating time = 1/3.

CO2 emissions were calculated using the receiving end coefficient of 4.1 t/10,000 kWh published by the Federation of Electric Power Companies of Japan.

Excellent functionality and usability facilitate on-site operations

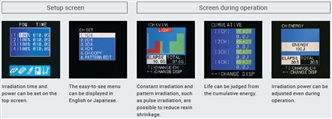

Easy-to-operate LCD display

The LCD display simplifies setting. Since it shows irradiation status during operation, UV curing can be performed without expert skills.

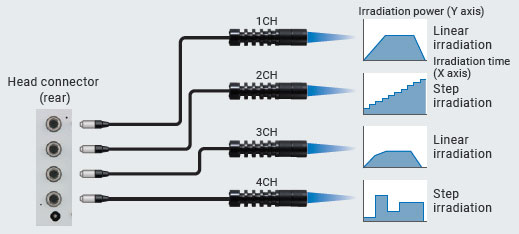

Programmed irradiation from each head

A single controller can independently control four heads.

This enables irradiation from different heads with different power, duration, and timing.

Irradiation patterns, such as step irradiation and linear irradiation, can be programmed.

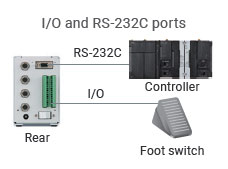

Multi-access link for external control and data transfer

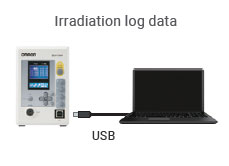

The multi-access link functionality enables external control via the I/O and RS-232C ports and data transfer to a PC via the USB port, providing great usability.

You can control inputs from the external devices via the I/O ports or the RS-232C port to start or stop irradiation, change irradiation patterns, and raise alarms.

The cumulative irradiation energy, counts, and other data can be transferred to a PC via USB. This is useful for storing quality data and analyzing failures.

The Power Tuning function is provided to compensate irradiation power based on the outputs from a luxmeter. Power can be simply compensated during a pre-operation check.

last update: May 16, 2022